An integrated module and power device

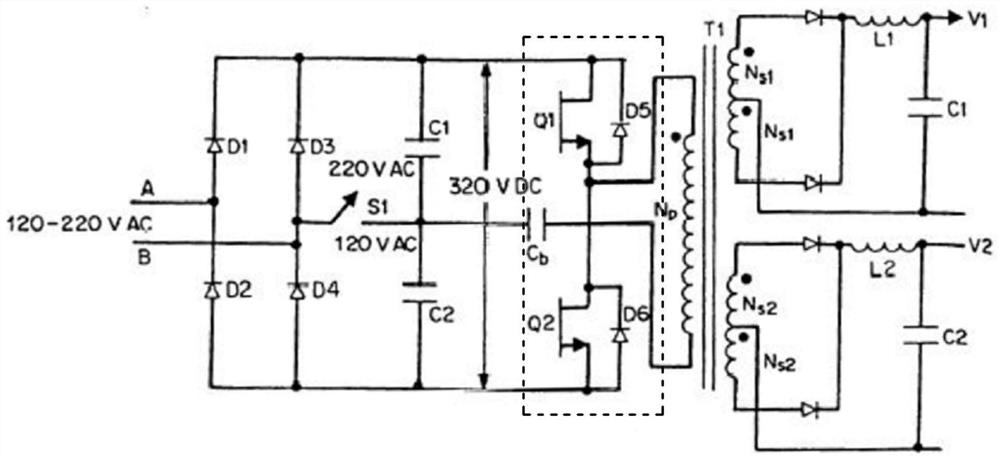

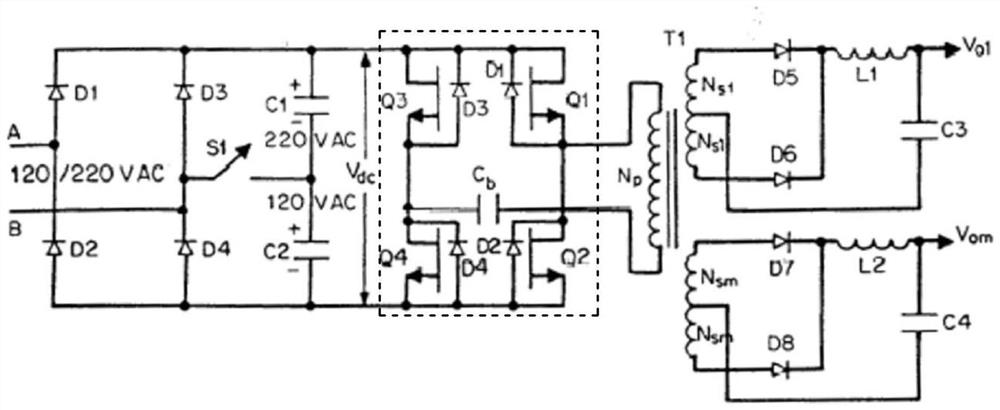

A technology for integrating modules and devices, applied in semiconductor devices, electro-solid devices, semiconductor/solid-state device components, etc., it can solve the problems of component aging failure, component damage, large current load, etc., and achieve high mold clamping and packaging pressure. , reduce parasitic inductance, reduce the effect of path and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

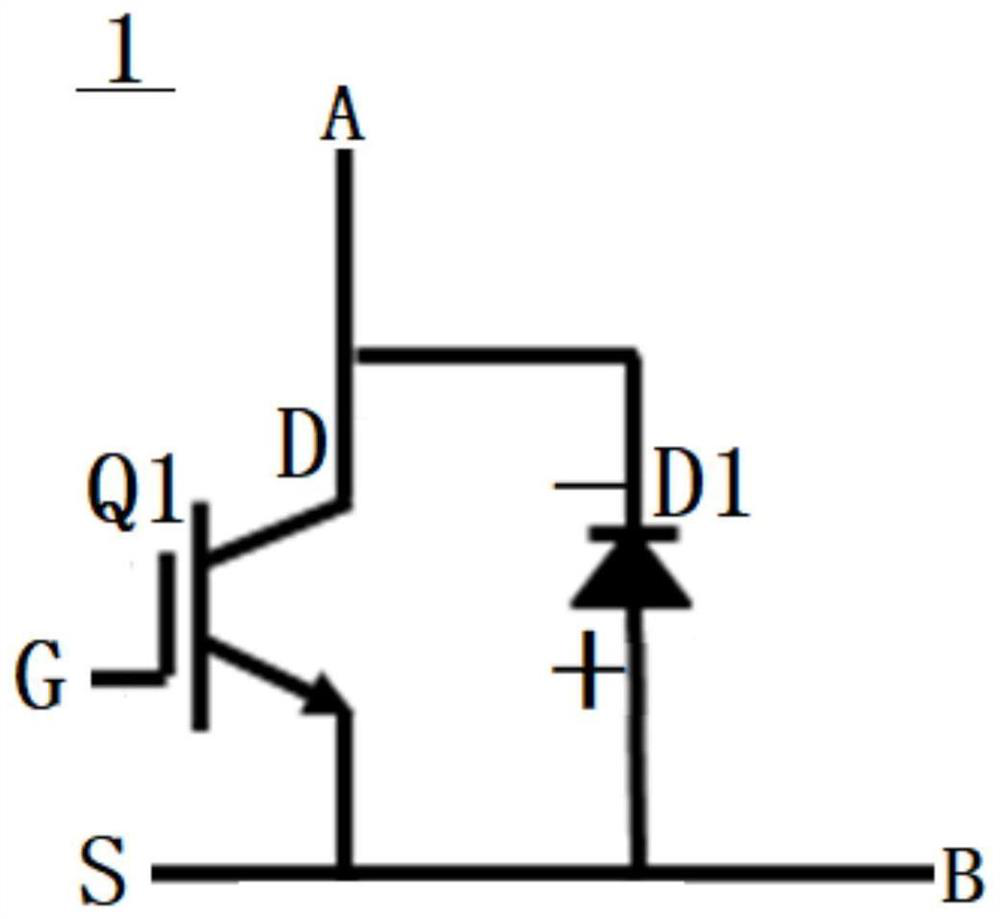

[0063] In the same device group, the cathode of the diode is bonded to the module substrate, and the drain of the switch transistor is bonded to the module substrate. Specifically, the device group to which this embodiment is applied is the first device group 10 . Specifically, in the embodiment of the present invention, the module substrate 3 is used as the O pole, corresponding to the image 3 In the circuit structure shown, the cathode of the first diode 101 is bonded to the second connection surface layer 312 of the module substrate, and the drain D01 of the first switch tube 102 is bonded to the module substrate 3 On the first connection surface layer 311 ; the gate G01 and the source S01 of the first switch tube 102 face away from the module substrate 3 .

Embodiment 2

[0065] In the same group of devices, the anode of the diode is bonded on the module substrate, and the source of the switch tube is bonded on the module substrate, and the module substrate corresponds to the switch The gate position of the tube is provided with a grid connector; the start and end of the grid connector pass through the two connection surfaces of the module substrate respectively, and the start end of the grid connector is connected to the switch tube the gate bonding; the connection remains insulated from the module substrate. Specifically, the device group to which this embodiment is applied is the second device group 20 .

[0066] Specifically, the module substrate 3 is used as the O pole, the anode of the second diode 201 is bonded to the first connection surface layer 311 of the module substrate 3, and the source S02 of the second switch tube 202 is bonded to combined on the second connection surface layer 312 of the module substrate 3; the module substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com