Mask manufacturing method and mask manufactured through method

A manufacturing method and mask technology, applied in application, textile and papermaking, protective clothing, etc., can solve problems such as entering the soil, silver ion poisoning, soil pollution, etc., and achieve the effect of lasting antibacterial effect, improving antibacterial effect, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of mouth mask, its manufacture method comprises the following steps:

[0061] (1) Material pretreatment: provide an intermediate filter layer and carry out antibacterial pretreatment on the intermediate filter layer with antibacterial liquid, wherein, the antibacterial liquid includes component A and component B, first use component A of antibacterial liquid to soak the intermediate filter layer, Then roll press, air-dry, then use antibacterial liquid B component to brush evenly to a surface of the middle filter layer and air-dry;

[0062] Wherein, the manufacture method of antibacterial liquid is as follows:

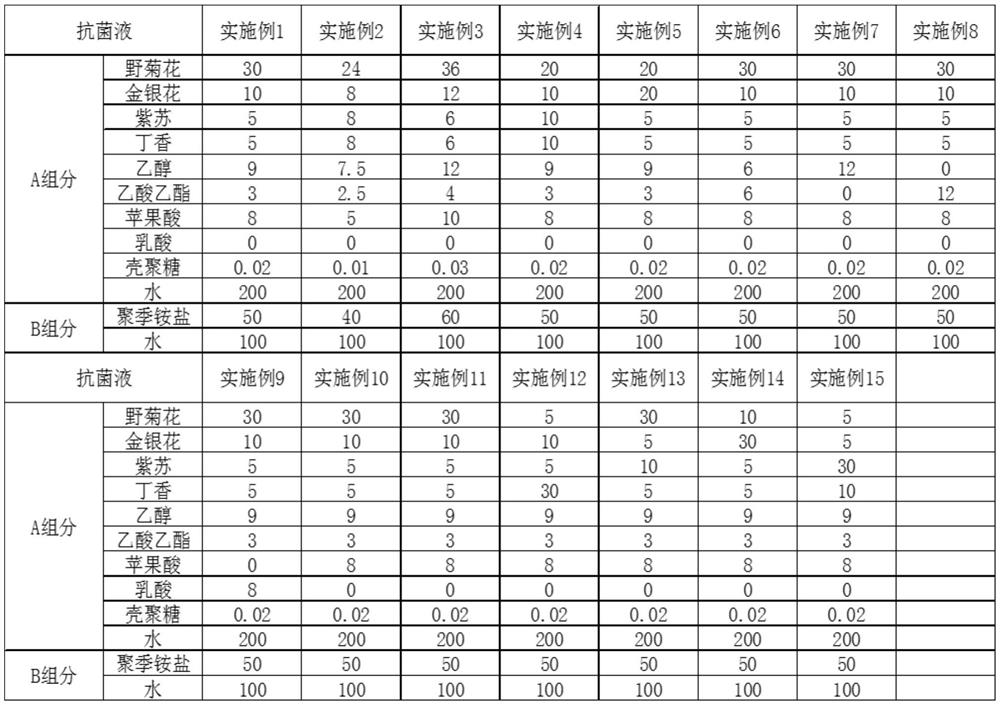

[0063] (1.1) Take by weighing 50kg of Chinese medicine composition according to the formula in table 1 and pulverize it to obtain pulverized mixture;

[0064] (1.2) Add a mixed solution of 200kg water and 12kg leaching accelerator to the pulverized mixture and stir to obtain a leachate mixture; wherein the leaching accelerator contains 9kg ethanol and 3kg...

Embodiment 2

[0071] A kind of mouth mask, the difference with embodiment 1 is:

[0072] In this embodiment, the total addition amount of the traditional Chinese medicine composition of antibacterial liquid A component is 40kg, the total addition amount of leaching accelerator is 10kg, the addition amount of malic acid is 5kg, the addition amount of chitosan is 0.01kg, the antibacterial The addition amount of the polyquaternium salt of liquid B component is 40kg, and the addition amount of water is 100kg.

Embodiment 3

[0074] A kind of mouth mask, the difference with embodiment 1 is:

[0075] In this embodiment, the total addition amount of the traditional Chinese medicine composition of antibacterial liquid A component is 60kg, the total addition amount of leaching accelerator is 16kg, the addition amount of malic acid is 10kg, the addition amount of chitosan is 0.03kg, antibacterial The addition amount of the polyquaternium salt of liquid B component is 60kg, and the addition amount of water is 100kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com