Treatment system for coal chemical industry wastewater

A treatment system and denitrification technology, applied in the field of coal chemical wastewater treatment system, can solve the problem of affecting the effect of pre-denitrification treatment and high dissolved oxygen content in effluent, and achieve the goal of improving efficiency, reducing carbon sources and reducing dissolved oxygen concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

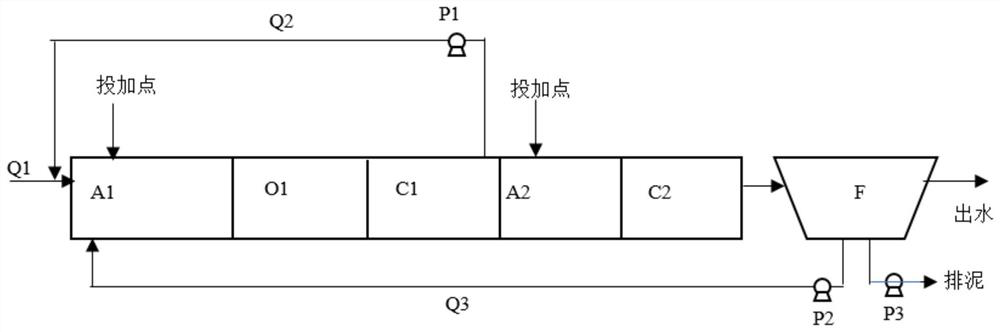

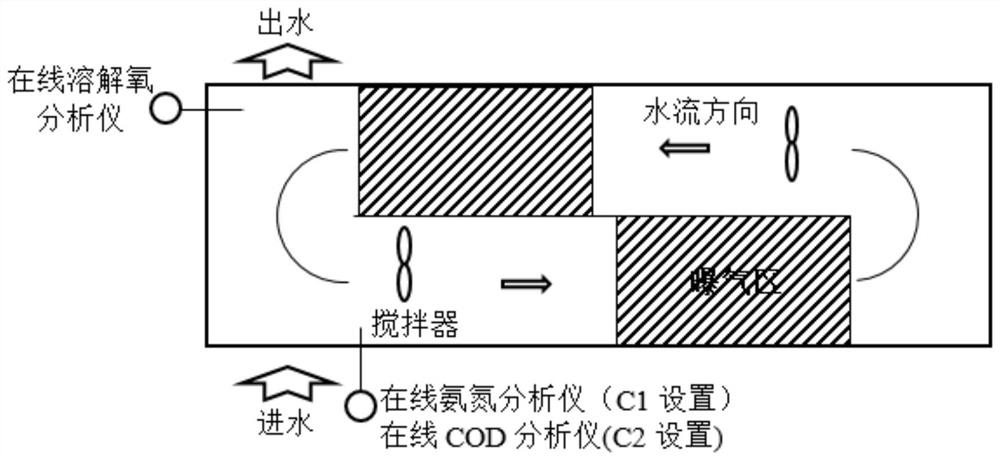

[0057] Such as figure 2 As shown, the treatment system for coal chemical wastewater according to the first embodiment of the present invention includes a front denitrification zone A1, a nitrification decarbonization zone O1, a first facultative oxygenation zone C1, a post denitrification zone A2, and a second denitrification zone. Facilitating zone C2, and secondary settling tank F. Among them, part of the mixed liquid in the first facultative zone C1 and part of the sludge in the secondary settling tank F are returned to the inlet of the pre-denitrification zone A1. To this end, the processing system also includes: a mixed liquid reflux pump P1 and corresponding pipelines, so that the reflux mixed liquid Q2 from the first facultative oxygenation zone C1 flows back to the inlet of the pre-denitrification zone A1, and the mixed liquid reflux pump P1 can It is a variable-frequency adjustable flow volumetric submersible pump; sludge return pump P2 and corresponding pipelines, so...

no. 2 example

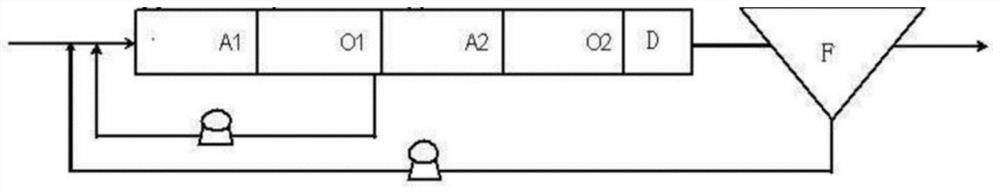

[0087] The treatment system for coal chemical wastewater according to the second embodiment of the present invention includes a front denitrification zone A1, a nitrification decarbonization zone O1, a post denitrification zone A2, and a secondary settling tank F. The front denitrification zone A1, the nitrification decarbonization zone O1, the post denitrification zone A2, and the secondary settling tank F according to the second embodiment are similar to those of the first embodiment, and the description thereof is omitted here. It should be noted that the thickness of the sludge bed in the secondary settling tank F according to the second embodiment can be kept within a suitable range, such as 1-2.5m, 1-2m, 1.5-2m, 1.5-2.5m, preferably 1.5-2.5m, promote the bottom sludge to be in a hydrolyzed state, the activated sludge itself hydrolyzes to produce absorbable organic matter as a carbon source, and denitrifies with the nitrate in the water to further remove the total nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com