Thermal-insulation sound-insulation fireproof colored steel sandwich plate and manufacturing process thereof

A fireproof and soundproof, sandwich panel technology, applied in the directions of heat preservation, sound insulation, fire prevention, etc., can solve the problems of insufficient consideration of the sound insulation performance of the color steel plate, insufficient adhesion between the core material and the steel plate, etc. Application prospect, high flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

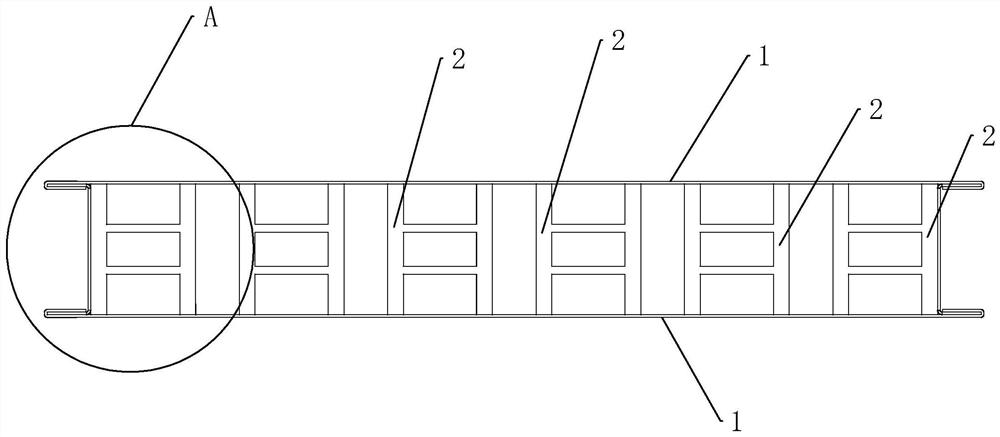

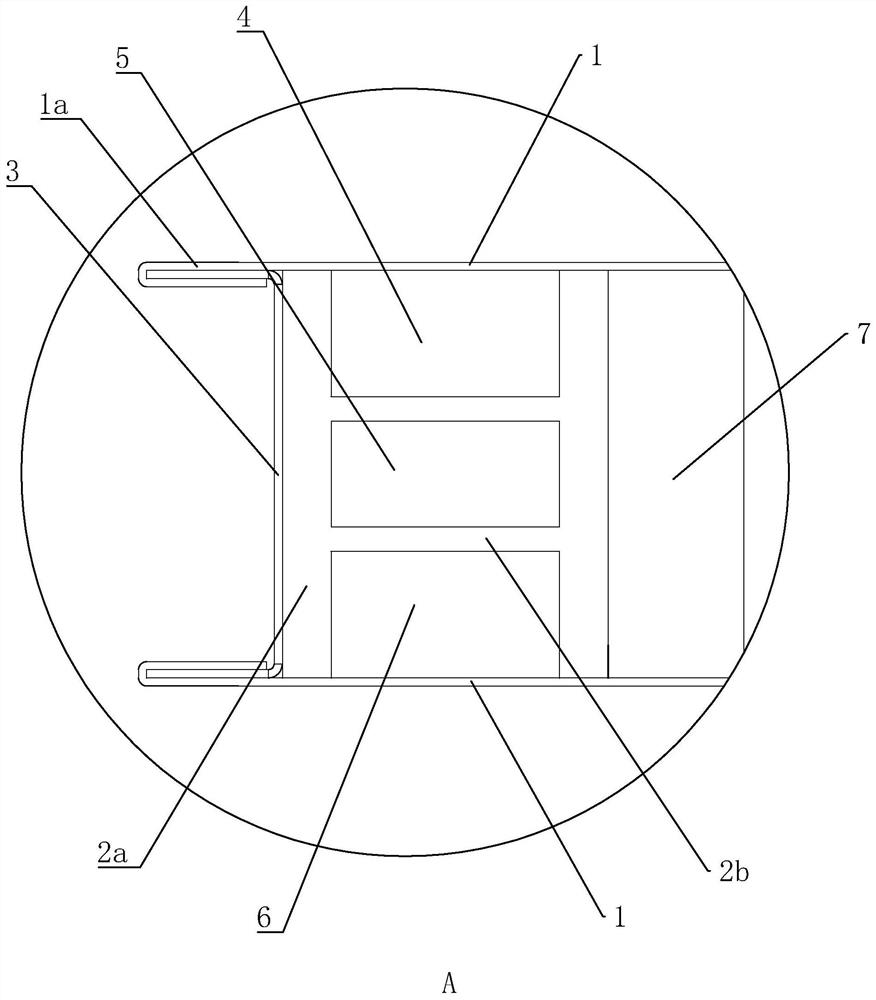

[0061] see Figure 1-3 , a heat-preserving, fire-proof and sound-insulating color steel sandwich panel, comprising two layers of color steel plates 1, two side plates 3, two sealing plates 8 and a core material, a plurality of keel frames 2 are arranged in the gaps of the core materials, and the keel frames 2 can improve the performance of the present invention. The structural strength of the color steel sandwich panel, the dragon frame 2 is made of glass magnesium plate material. The glass magnesium board material has good fire performance and is non-combustible, which can improve the fire protection level of the color steel sandwich panel, and has high structural strength, which can improve the pressure bearing capacity of the color steel sandwich panel. It should be noted that in other embodiments , the dragon skeleton 2 can be made of other types of materials, as long as the strength can be achieved. The keel frame 2 includes two horizontal plates 2a and two vertical plat...

Embodiment 2

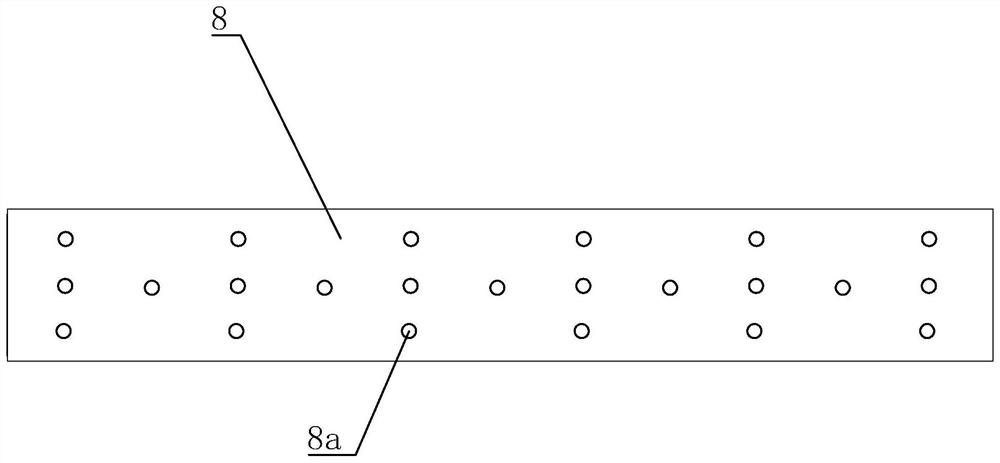

[0079] A heat-preserving, fire-proof and sound-insulating color steel sandwich panel. The shape and structure of this embodiment is basically the same as that of Embodiment 1, the only difference being that the second cavity 5 of this embodiment has been vacuumized. The vacuum environment can block the transmission and heat conduction, which plays a vital role in reducing the thermal conductivity of the material. In addition, the vacuum environment does not transmit sound, which enhances the sound insulation performance of the color steel sandwich panel. The manufacturing process of this embodiment is basically the same as that of Embodiment 1, the difference is that in the sealing step, only the through holes 8a communicating with the first chamber 4, the third chamber 6 and the fourth chamber 7 are blocked, and after natural foaming, the The color steel sandwich panel is vacuumed to a vacuum degree of -0.09Mpa~-0.12Mpa, and the through hole 8a communicating with the second ca...

Embodiment 3

[0082] A method for manufacturing heat-preserving, fire-proof and sound-insulating color-steel sandwich panels. The color-steel sandwich panels produced by the process have good sound insulation performance, high structural strength, high repeatability of the operation process, and are convenient for mechanized and automatic processing.

[0083] see Figure 1-3 , a method for making heat-preserving, fire-proof and sound-insulating color-steel sandwich panels, comprising the following steps:

[0084] S1. Floor laying: first lay the bottom color steel plate 1 on the operating table;

[0085] S2. Lay the keel frame 2: apply the adhesive on the top and bottom surfaces of the longitudinal plates 2b, and evenly arrange several keel frames 2 on the color steel plate 1, leaving gaps between two keel frames 2;

[0086] S4, roof laying: laying the top color steel plate 1 on the keel frame 2;

[0087] S5. Erection of side panels 3: Insert the folded edges at the bottom of the two "匚"-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com