Mining reamer bit

A technology for reaming drill bits and drill bits, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of high maintenance and maintenance costs, poor device reliability, and large stress impact, and achieves reduction of maintenance and maintenance costs. The structure is simple and efficient. The effect of reaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

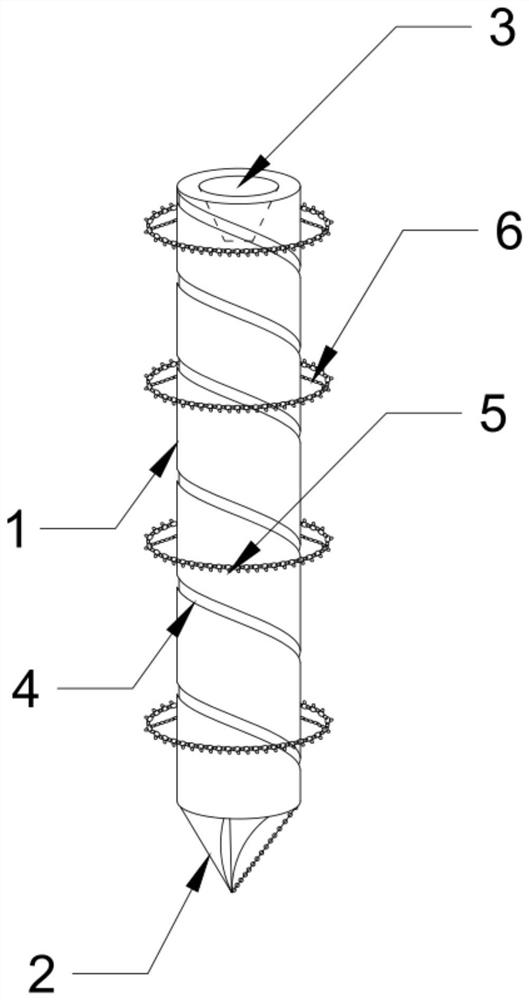

[0019] Such as figure 1 As shown, the present invention provides a mining reaming drill bit, comprising a drill bit body 1, one end of the drill bit body 1 is provided with a drill point 2, and the other end is provided with a threaded inner hole 3 for connecting a drill rod, the drill bit The outer circular surface of the main body 1 is provided with a spiral guide groove 4, the drill tip 2 is provided with a drill edge, and the drill edge is provided with a tungsten carbide diamond composite wear-resistant layer, and the outer circular surface of the drill bit body 1 There are multiple rings of ring-shaped swing chains 5 at intervals along the axial direction, and a swing gap is left between the ring-shaped swing chains 5 and the outer circular surface of the drill body 1, and the side of the ring-shaped swing chain 5 away from the drill body 1 Diamond composite sheets are evenly distributed.

[0020] Two flexible connectors 6 are evenly distributed on the side of the ring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com