Integrated tester and test method for shock absorption, noise reduction and impact resistance performance of composite materials

A technology of impact resistance and composite materials, applied in the direction of analytical materials, instruments, measuring devices, etc., can solve problems such as low integration, changes in inherent characteristic parameters, high cost, etc., achieve comprehensive test indicators, reduce costs, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the embodiments and drawings, but the protection scope of the present invention is not limited by the embodiments and drawings.

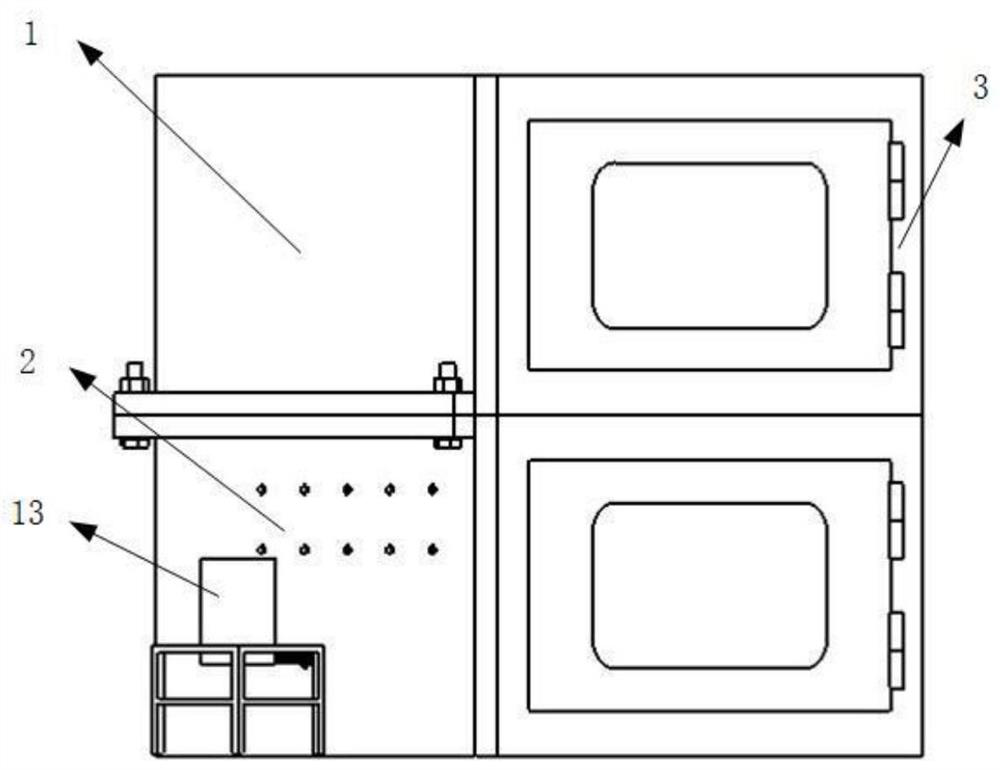

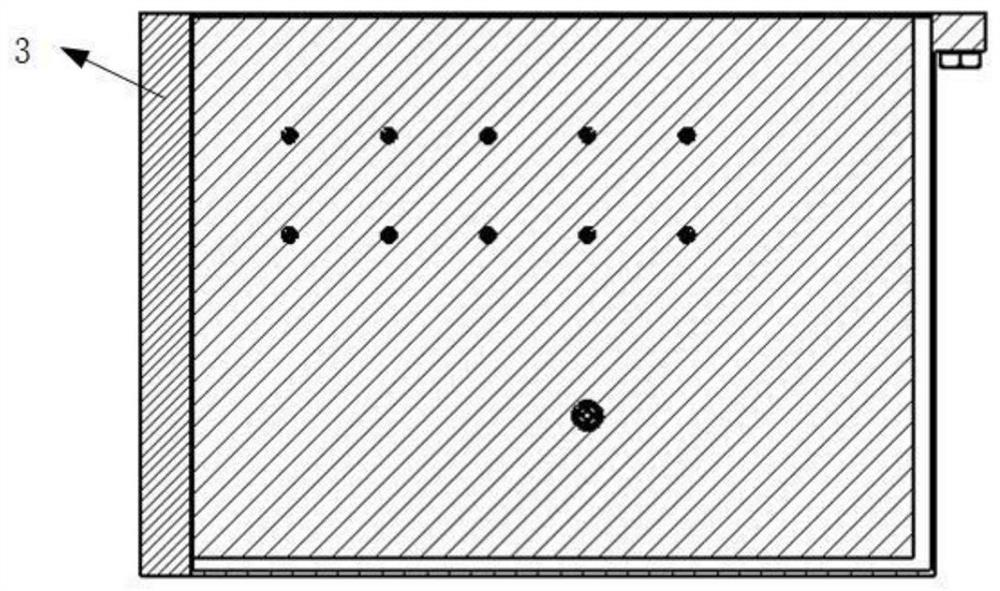

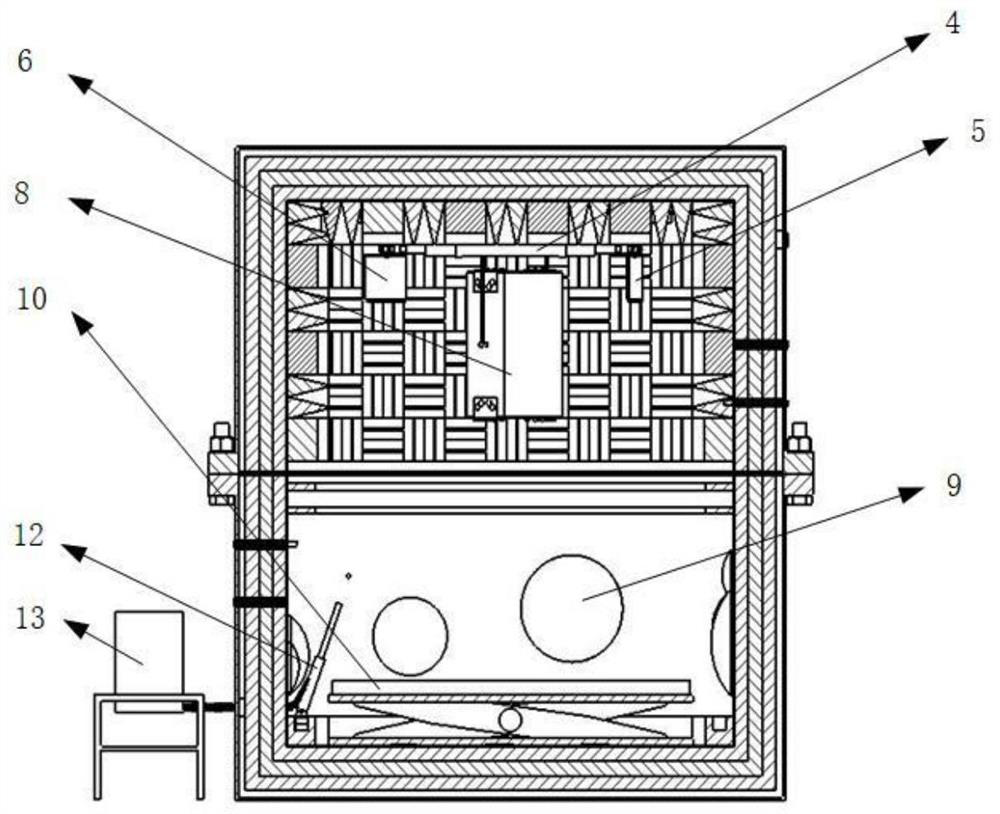

[0054] figure 1 It is the external outline diagram of the integrated tester system for shock absorption, noise reduction and impact resistance performance of composite materials according to the specific embodiment of the present invention, figure 2 It is a diagram of the perforation channel of the composite material shock absorption, noise reduction and impact resistance performance integrated tester system according to the specific embodiment of the present invention, image 3 It is the internal structure diagram of the integrated tester system for shock absorption, noise reduction and impact resistance performance of composite materials according to the specific embodiment of the present invention. Figure 4 It is a schematic diagram of the perforated fixture in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com