Integrated circuit board structure of electrochemical detection electrode and manufacturing method of integrated circuit board structure

A detection electrode and integrated circuit technology, applied in chemical instruments and methods, structural connection of printed circuits, printed circuit manufacturing, etc., can solve the problem that vertical graphene electrodes cannot detect equipment combination costs, etc., and is conducive to chip and integration The effects of simplification, ease of mass production, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

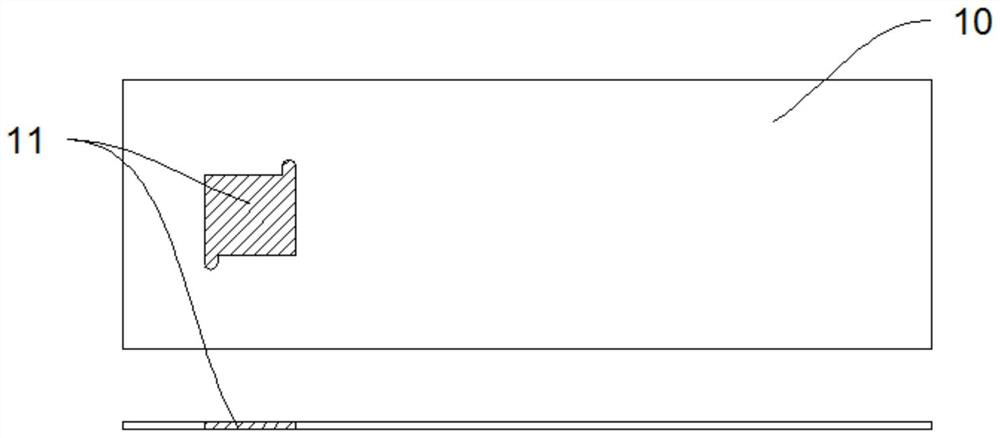

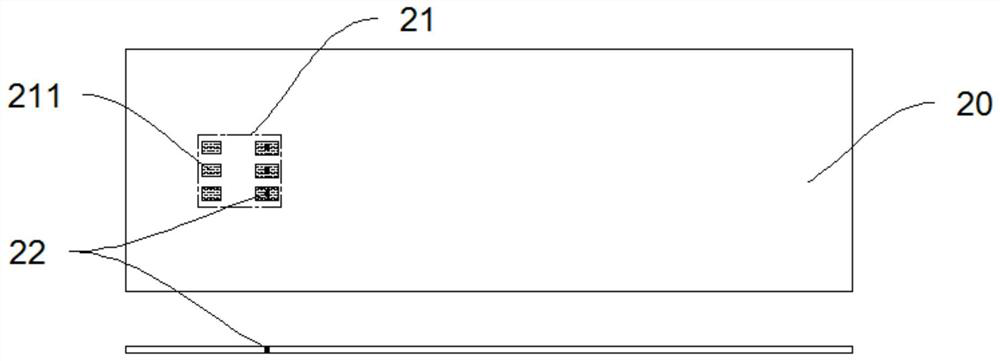

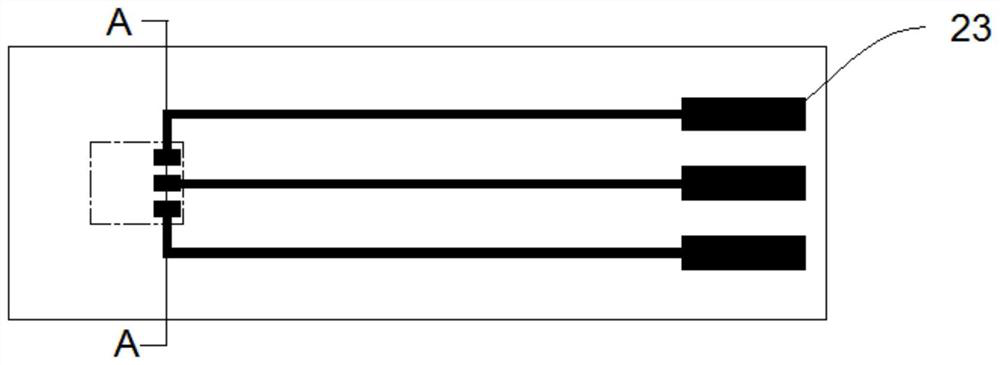

[0036] like Figure 1-4 As shown, the integrated circuit board structure of an electrochemical detection electrode of the present invention includes a first substrate 10 and a second substrate 20 connected together up and down, and the first substrate 10 and the second substrate 20 are glass fiber plates, Non-conductive material plates such as ceramic plates or glass plates, the thickness of which is 0.2-0.3mm. Connected together by pressing. The first substrate 10 is provided with a window opening 11 , and the second substrate 20 is provided with a connection end 21 at a position corresponding to the window opening 11 , and the connection end 21 includes a plurality of pads 211 . The number of pads is 2-6, and at least two pads 211 are provided with pins 22 respectively. In this embodiment, there are 6 pads 211 in each connection end 21, am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com