Method and apparatus for producing positive electrode active material for secondary battery

A positive electrode active material and secondary battery technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, nickel compounds, etc., can solve the problem of uneven particle size and composition, reduced productivity, retention time and reaction time. Changes and other issues, to achieve the effect of easy particle size control, uniform particle size, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

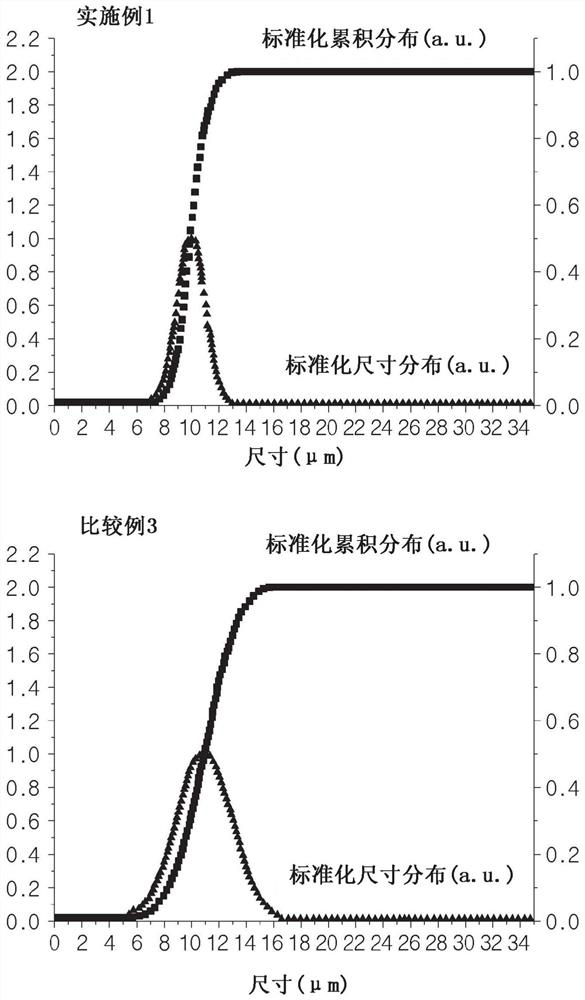

Embodiment 1

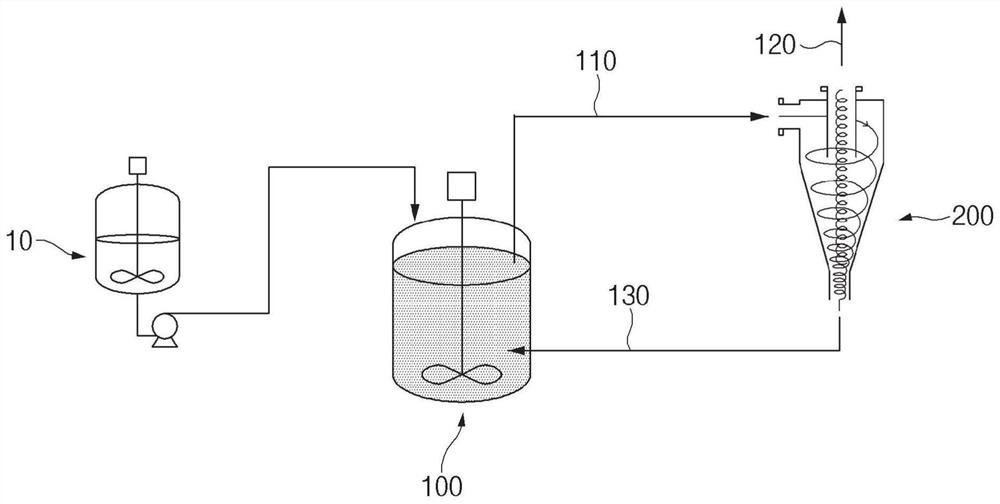

[0120] NiSO 4 、CoSO 4 and MnSO 4 The nickel:cobalt:manganese molar ratio was mixed in water in an amount of 80:10:10 to prepare a transition metal-containing solution with a concentration of 2M. The reactor containing the transition metal-containing solution was connected to a 20 L batch reactor set at 60°C. Additionally, prepare 25 wt% aqueous NaOH and 15 wt% NH 4 OH aqueous solution and connect them to batch reactors respectively.

[0121] 4 L of deionized water was put into the batch reactor, and then the reactor was purged with nitrogen gas at a rate of 2 L / min to remove dissolved oxygen in the water and create a non-oxidizing atmosphere in the reactor. Afterwards, 25 ml of 50 wt% aqueous NaOH and 500 ml of 15 wt% NH 4 OH aqueous solution, and then stirred at a speed of 500 rpm and a temperature of 55° C. to maintain a pH of 12.2.

[0122] Afterwards, the transition metal-containing solution, NaOH aqueous solution and NH 4 OH aqueous solution, and reacted for 30 min...

Embodiment 2

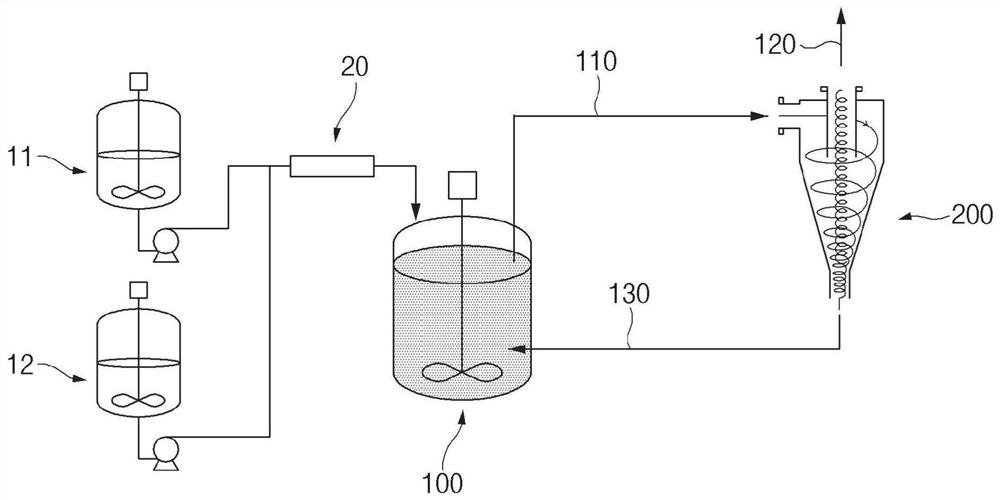

[0125] As a solution containing transition metals, NiSO 4 、CoSO 4 and MnSO 4 Mix in water in such an amount that the molar ratio of nickel:cobalt:manganese is 95:2.5:2.5 to prepare a first transition metal-containing solution with a concentration of 2M, and NiSO 4 、CoSO 4 and MnSO 4Nickel:cobalt:manganese was mixed in water in such an amount that the molar ratio of nickel:cobalt:manganese was 50:25:25 to prepare a second transition metal-containing solution having a concentration of 2M. A first transition metal-containing solution reactor and a second transition metal-containing solution reactor containing the first transition metal-containing solution and a second transition metal-containing solution, respectively, are connected to the static mixer, respectively, and the divided A batch reactor (20 L) was connected to the outlet side of the static mixer. Additionally, prepare 25 wt% aqueous NaOH and 15 wt% NH 4 OH aqueous solution and connect them to the reactor respect...

Embodiment 3

[0129] When the batch reactor (20 L) was full, the addition of the transition metal-containing solution, aqueous NaOH and NH 4 OH aqueous solution, the reaction slurry in the batch reactor is conveyed to the hydrocyclone through the transfer line by the pump, and the concentrated The reaction slurry was then introduced into the batch reactor. Except after the concentrated reaction slurry was reintroduced into the batch reactor until the reactants in the batch reactor reached 4L, by adding the transition Metal solutions, NaOH aqueous solution and NH 4 OH aqueous solution to initiate the reaction, prepare Ni in the same manner as in Example 1 0.8 co 0.1 mn 0.1 (OH) 2 precursor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com