Process for recycling waste mortar during solar silicon wafer slicing

A technology of solar silicon wafers and cutting waste sand, which is applied in the direction of detergent compounding agent, non-ionic surface active compound, detergent composition, etc., can solve the problems of large sewage treatment and other environmental protection costs, and the cost increase of environmental protection equipment products. Achieve the effects of easy particle size control, high yield and less breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

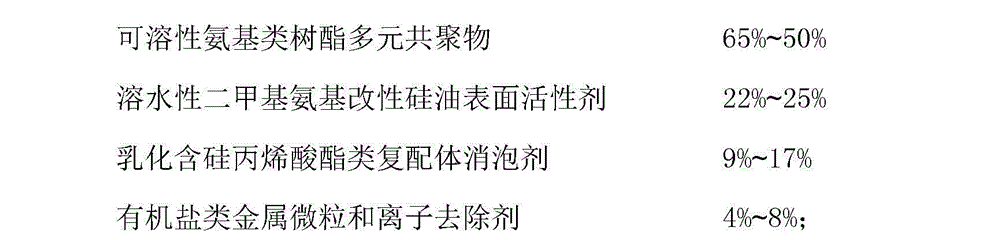

Method used

Image

Examples

Embodiment Construction

[0020] The process steps of the present invention are described in detail below by taking the treatment of 100kg wire-cutting waste mortar as a specific example, solid-liquid separation, and liquid and sand are carried out to remove impurities and purify respectively;

[0021] The first step of grading and surface cleaning of the separated sand: Weigh 100kg of separated sand and add it to 300kg of polyethylene glycol mixture containing 5% sand cleaning solution, stir for 75 minutes with different stirring speeds according to the program, and then add the mortar to the solid-liquid separation system, part of the unusable sand is discharged together with the mixed liquid, and the separation liquid is adjusted and separated for the second time to prepare a new cleaning liquid, and the reusable separated sand enters the second step of surface cleaning treatment;

[0022] The first step of grading and surface cleaning of separated sand: Weigh 80kg of sand from the available separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com