High-performance reaction kettle stirrer for chemical machinery

A technology of chemical machinery and kettle stirrer, which is applied in chemical/physical/physical chemical fixed reactors, mixer accessories, chemical instruments and methods, etc., and can solve problems such as inability to pulverize, uneven mixing of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

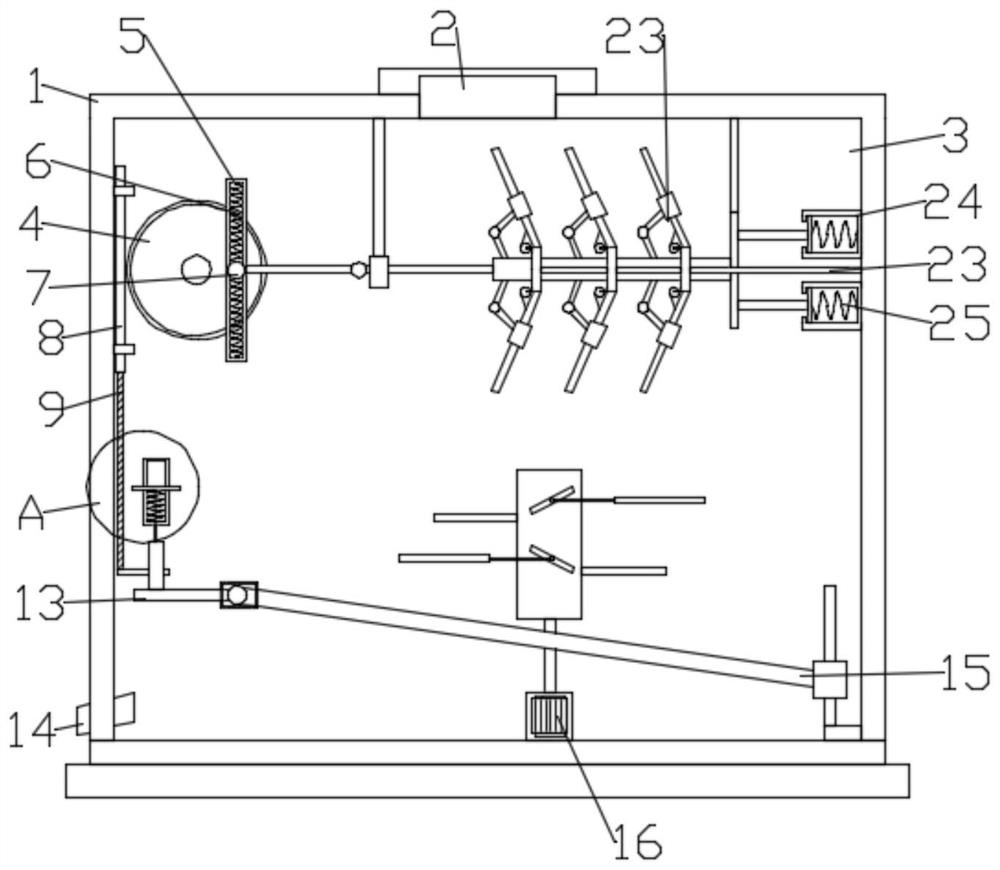

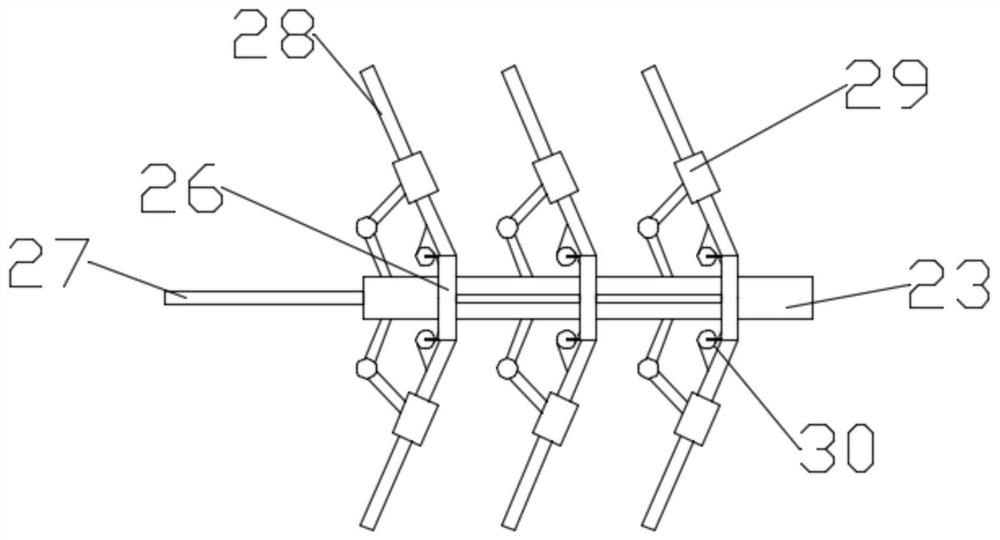

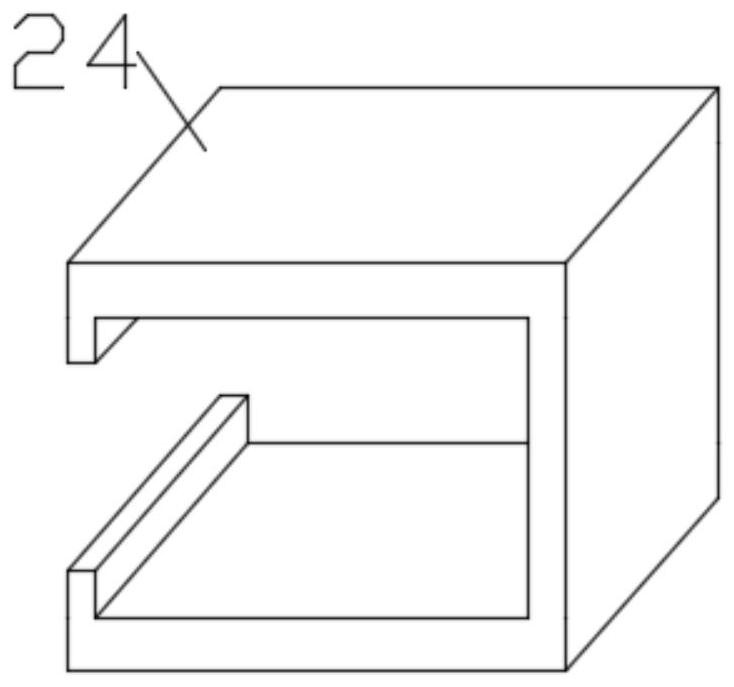

[0021] Such as figure 1 As shown, in the embodiment of the present invention, a high-performance reaction kettle agitator for chemical machinery includes a kettle body 1 and a feeding port 2. The bottom of the kettle body 1 is fixedly installed on a buffer base, and the buffer base is made of an elastomer material. In addition, a stirring chamber 3 is provided in the kettle body 1, and a feeding port 2 is provided at the center of the upper surface of the kettle body 1, and the feeding port 2 and the stirring chamber 3 are connected, and a driving assembly is provided in the stirring chamber 3, and the driving assembly A mixing component is connected, and a crushing component 16 is arranged below the mixing component;

[0022] The drive assembly includes a servo motor, the servo motor is fixedly installed on the side wall of the kettle body 1, and the output end of the servo motor is fixedly connected with a worm gear 4, and the front side wall of the worm gear 4 is fixedly eq...

Embodiment 2

[0030] Such as figure 1 As shown, in the embodiment of the present invention, a high-performance reaction kettle agitator for chemical machinery includes a kettle body 1 and a feeding port 2. The bottom of the kettle body 1 is fixedly installed on a buffer base, and the buffer base is made of an elastomer material. In addition, a stirring chamber 3 is provided in the kettle body 1, and a feeding port 2 is provided at the center of the upper surface of the kettle body 1, and the feeding port 2 and the stirring chamber 3 are connected, and a driving assembly is provided in the stirring chamber 3, and the driving assembly A mixing component is connected, and a crushing component 16 is arranged below the mixing component;

[0031] The drive assembly includes a servo motor, the servo motor is fixedly installed on the side wall of the kettle body 1, and the output end of the servo motor is fixedly connected with a worm gear 4, and the front side wall of the worm gear 4 is fixedly eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com