High-permeability wide-temperature-range power type nickel-zinc LTCF material as well as preparation method and application thereof

A high-permeability, power-type technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of large decrease in magnetic permeability and failure to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

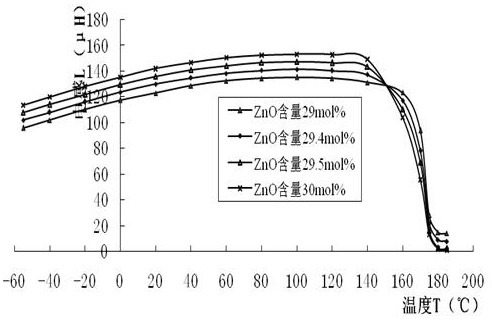

[0028] A high magnetic permeability wide temperature power type nickel-zinc LTCF material, the specific composition percentage is: main component content: NiO 15.50mol%, ZnO 29.50mol%, CuO 7.00mol%, Fe 2 o 3 48.00 mol%,

[0029] The auxiliary component content: MnCO 3 0.40wt%, Bi 2 o 3 0.30wt%;

[0030] The preparation method is as follows:

[0031] First of all, the high-frequency vibrating mixing system is used to effectively improve the mixing uniformity of the oxides of various raw materials, to achieve the effect of high-speed primary crushing, to complete the dry mixing, and to control the mixing time to 55 minutes, and then to further use the sintering kiln for pre-sintering to control the pre-sintering The temperature is 850°C;

[0032] Further, large-flow circulating sand mill wet abrasive (4 hours for primary abrasive, 4.5 hours for secondary fine abrasive) is used to refine powder particles to improve powder activity, reduce reaction activation energy and e...

Embodiment 2

[0041] A high magnetic permeability wide temperature power type nickel-zinc LTCF material, the specific composition percentage is: main component content: NiO 15.00mol%, ZnO 29.00mol%, CuO 6.50mol%, Fe 2 o 3 49.50 mol%,

[0042] The auxiliary component content: MnCO 3 0.30wt%, Bi 2 o 3 0.40wt%.

[0043] The preparation method is as follows:

[0044] First of all, the high-frequency vibrating mixing system is used to effectively improve the mixing uniformity of the oxides of various raw materials, to achieve the effect of high-speed primary crushing, to complete the dry mixing, and to control the mixing time to 45 minutes, and then to further use the sintering kiln for pre-sintering to control the pre-sintering The temperature is 860°C;

[0045] Further, large-flow circulating sand mill wet abrasive (4 hours for primary abrasive, 4.5 hours for secondary fine abrasive) is used to refine powder particles to improve powder activity, reduce reaction activation energy and e...

Embodiment 3

[0048] A high magnetic permeability wide temperature power type nickel-zinc LTCF material, the specific composition percentage is: main component content: NiO 15.80mol%, ZnO 29.40mol%, CuO 6.80mol%, Fe 2 o 3 48.00 mol%,

[0049] The auxiliary component content: MnCO 3 0.35wt%, Bi 2 o 3 0.35wt%.

[0050] The preparation method is as follows:

[0051] First of all, the high-frequency vibrating mixing system is used to effectively improve the mixing uniformity of the oxides of various raw materials, to achieve the effect of high-speed primary crushing, to complete the dry mixing, and control the mixing time to 50 minutes, and then further use the sintering kiln for pre-sintering to control the pre-sintering The temperature is 840°C;

[0052] Further, large-flow circulating sand mill wet abrasive (4 hours for primary abrasive, 4.5 hours for secondary fine abrasive) is used to refine powder particles to improve powder activity, reduce reaction activation energy and effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sintering temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com