Resin cementing material for oil-gas well as well as preparation method and application thereof

A technology of resin glue and oil and gas wells, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of corrosion resistance, inability to change completely, and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

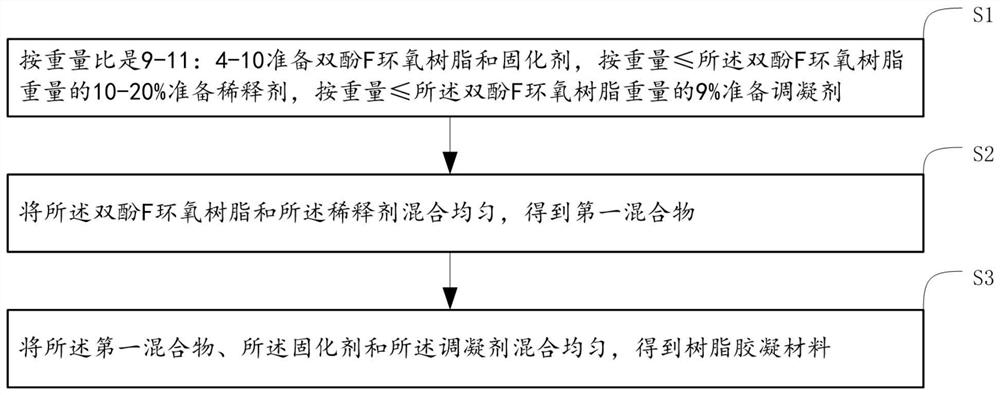

[0058] On the other hand, if figure 1 As shown, the embodiment of the present invention also provides a method for preparing a resin gelling material for oil and gas wells, the method comprising:

[0059] S1, prepare bisphenol F epoxy resin and curing agent by weight ratio of 9-11: 4-10, prepare diluent by weight ≤ 10-20% of the weight of the bisphenol F epoxy resin, by weight ≤ the described 9% of bisphenol F epoxy resin weight prepares coagulant;

[0060] S2, uniformly mixing the bisphenol F epoxy resin and the diluent to obtain a first mixture;

[0061] S3, uniformly mixing the first mixture, the curing agent and the coagulation regulator to obtain a resin cementitious material for oil and gas wells.

[0062] After mixing the bisphenol F epoxy resin and the diluent, the reason for adding the curing agent and the coagulation agent is that the simple mixing of the resin and the diluent will not cause a curing reaction, and the mixture obtained after mixing the two can be us...

Embodiment 1

[0070] At room temperature, add 100 parts of bisphenol F epoxy resin NPEF-170 into a beaker, add 20 parts of diluent dodecyl glycidyl ether, stir evenly, and let stand for 5 minutes. Add 40 parts of curing agent 3,3'-diethyl-4,4'-diaminodiphenylmethane into the beaker and stir evenly.

Embodiment 2

[0072] The difference between this example and Example 1 is that: after adding the curing agent and stirring evenly, add 0.5 parts of coagulation regulator N, N-dimethylaniline. The performance test method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com