Cold liquid heat exchange system and liquid cooling system

A technology of heat exchange system and cold liquid, applied in indirect heat exchangers, cooling/ventilation/heating transformation, lighting and heating equipment, etc., can solve the problems of reducing the deployment density of server cabinets, occupying a large space, and system failure, etc. Achieve low cost, ensure uninterrupted work, and enhance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

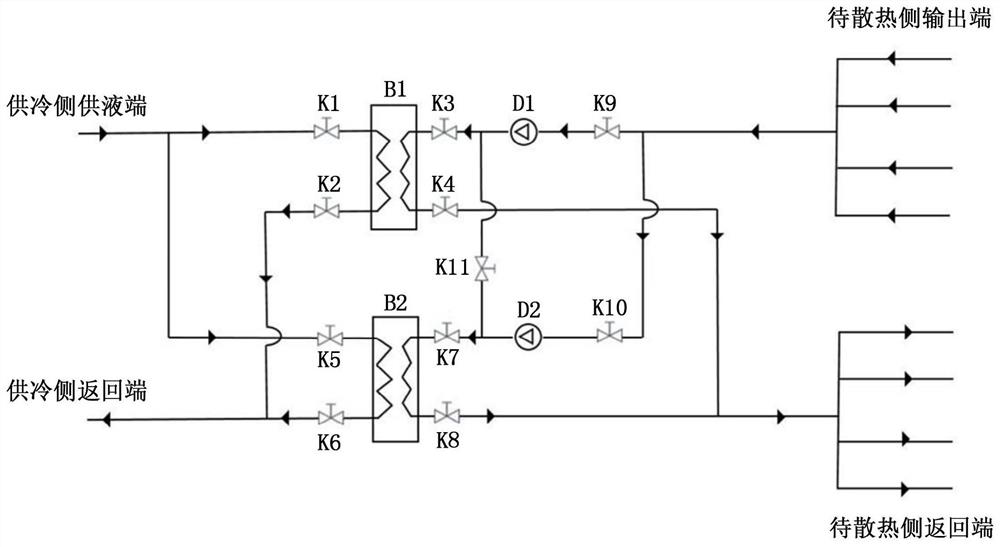

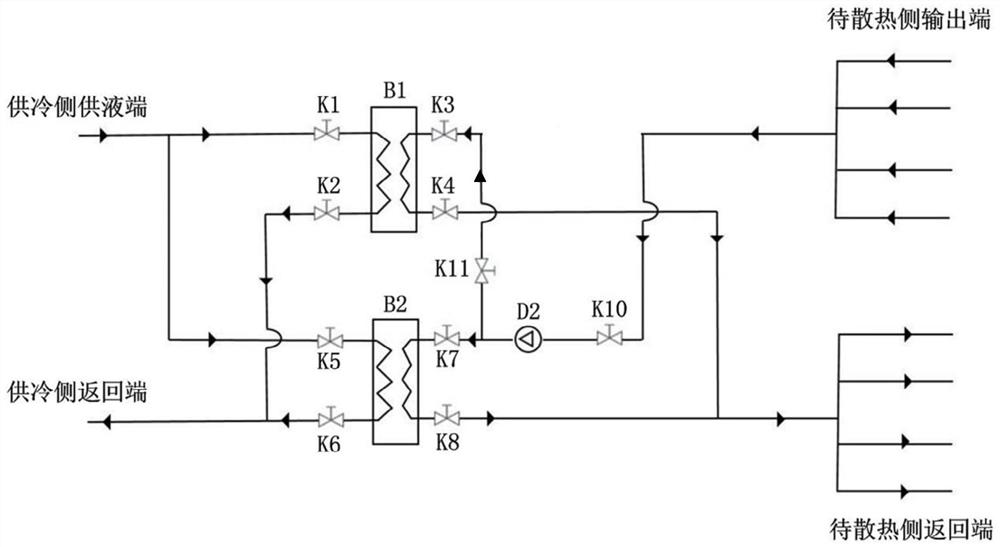

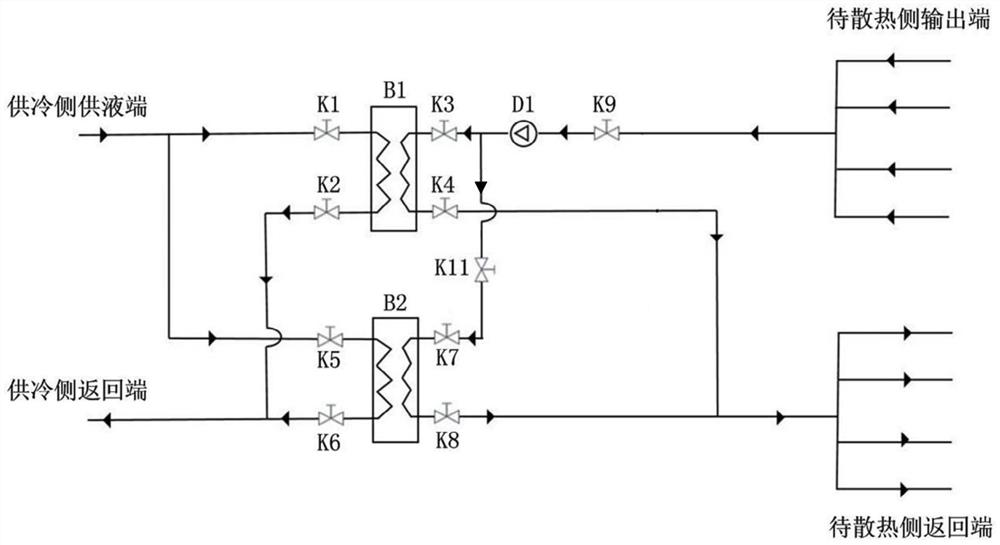

[0030] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding and should be considered as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted from the following description for clarity and conciseness.

[0031] In the existing CDU redundancy technical solutions, only the liquid conveying device (such as a pump) is redundant, which cannot cope with the failure of the heat exchanger; or two CDUs are used as backups for each other, which will increase the cost and occupy the larger space. In view of the above defects, in the embodiment of the present invention, a single CDU can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com