Lithium metal negative electrode protection method for improving lithium utilization efficiency

A lithium metal negative electrode, lithium metal technology, applied in the direction of negative electrode, positive electrode, electrode manufacturing, etc., can solve the problems of low Coulombic efficiency, inhomogeneous side reaction activity, low cycle capacity retention rate of lithium battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

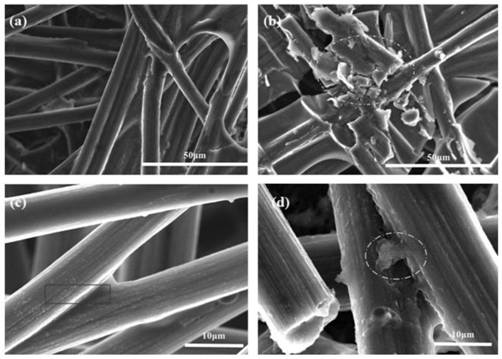

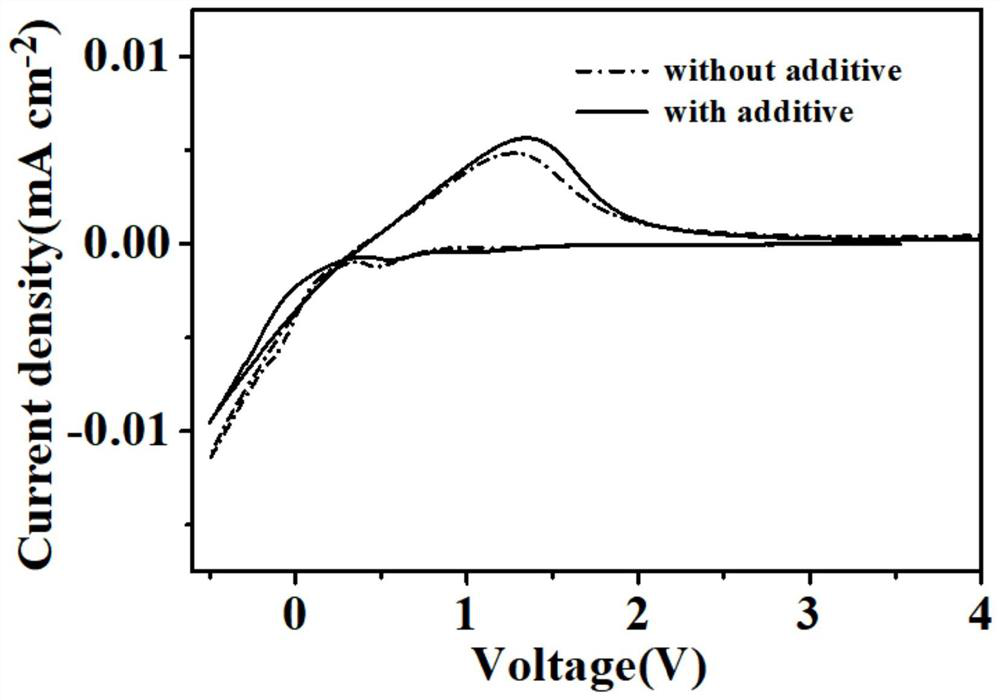

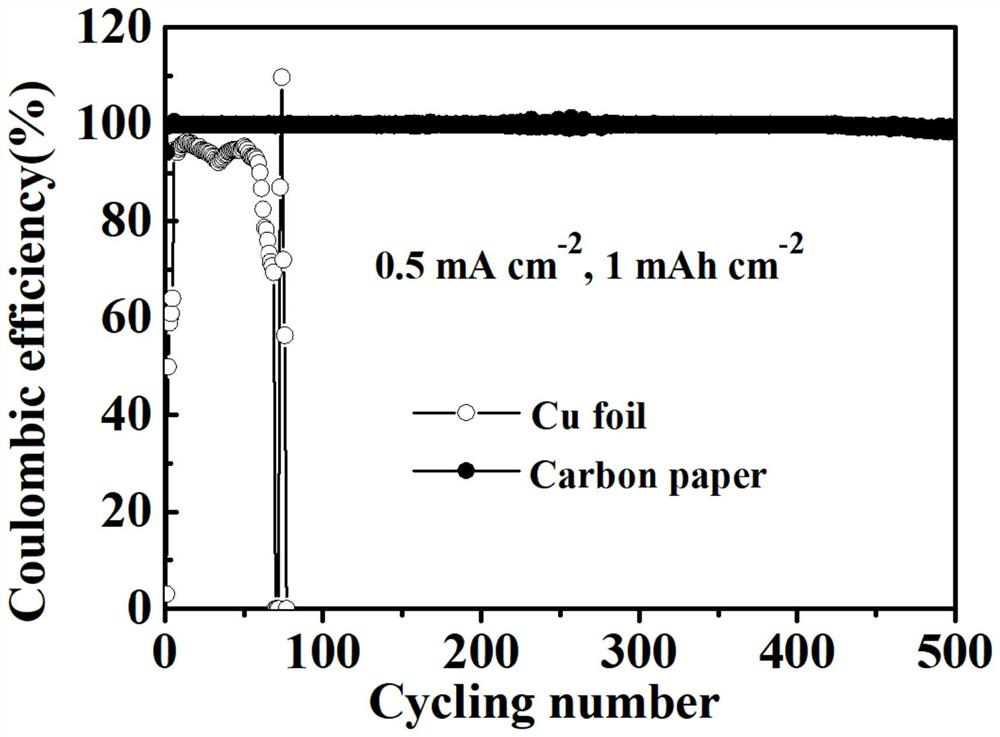

[0028] This embodiment provides a lithium metal negative electrode protection method that improves lithium utilization efficiency. In lithium batteries: the lithium metal deposited on the current collector is used as the negative electrode of the battery, where the current collector is carbon paper, and the capacity of lithium metal deposited on the current collector is 0.6mAh / cm 2 ; Lithium iron phosphate is used as the positive electrode of the battery; the polymer is added as an additive to the ester electrolyte, and the amount of the polymer added is 2wt% of the ester electrolyte.

[0029] The above-mentioned process of depositing lithium metal on the current collector as the negative electrode of the battery includes: first assembling a half-cell with the positive electrode carbon paper and the negative electrode lithium sheet, and depositing a certain capacity of metal on the carbon paper by setting the current density and time constant current discharge. Lithium, and th...

Embodiment 2

[0033] This embodiment provides a lithium metal negative electrode protection method that improves lithium utilization efficiency. In lithium batteries: the lithium metal deposited on the current collector is used as the negative electrode of the battery, where the current collector is carbon paper, and the capacity of lithium metal deposited on the current collector is 0.1mAh / cm 2 ; Lithium iron phosphate is used as the positive electrode of the battery; the polymer is added as an additive to the ester electrolyte, and the amount of the polymer added is 2wt% of the ester electrolyte.

[0034] The above-mentioned process of depositing lithium metal on the current collector as the negative electrode of the battery includes: first assembling a half-cell with the positive electrode carbon paper and the negative electrode lithium sheet, and by setting the current density and time constant current discharge, a certain capacity will be deposited on the carbon paper. Lithium metal, a...

Embodiment 3

[0038] This embodiment provides a lithium metal negative electrode protection method that improves lithium utilization efficiency. In a lithium battery: the lithium metal deposited on the current collector is used as the negative electrode of the battery, where the current collector is carbon paper, and the capacity of lithium metal deposited on the current collector is 5mAh / cm 2 ; Lithium iron phosphate is used as the positive electrode of the battery; the polymer is added as an additive to the ester electrolyte, and the amount of the polymer added is 2wt% of the ester electrolyte.

[0039] The above-mentioned process of depositing lithium metal on the current collector as the negative electrode of the battery includes: first assembling a half-cell with the positive electrode carbon paper and the negative electrode lithium sheet, and by setting the current density and time constant current discharge, a certain capacity will be deposited on the carbon paper. Lithium metal, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com