Medical waste treatment device based on compression crushing treatment technology

A technology of medical waste and treatment equipment, which is applied in the field of medical waste treatment equipment based on compression and pulverization treatment technology, which can solve the problems of inability to sterilize medical waste, endanger the personal safety of operators, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

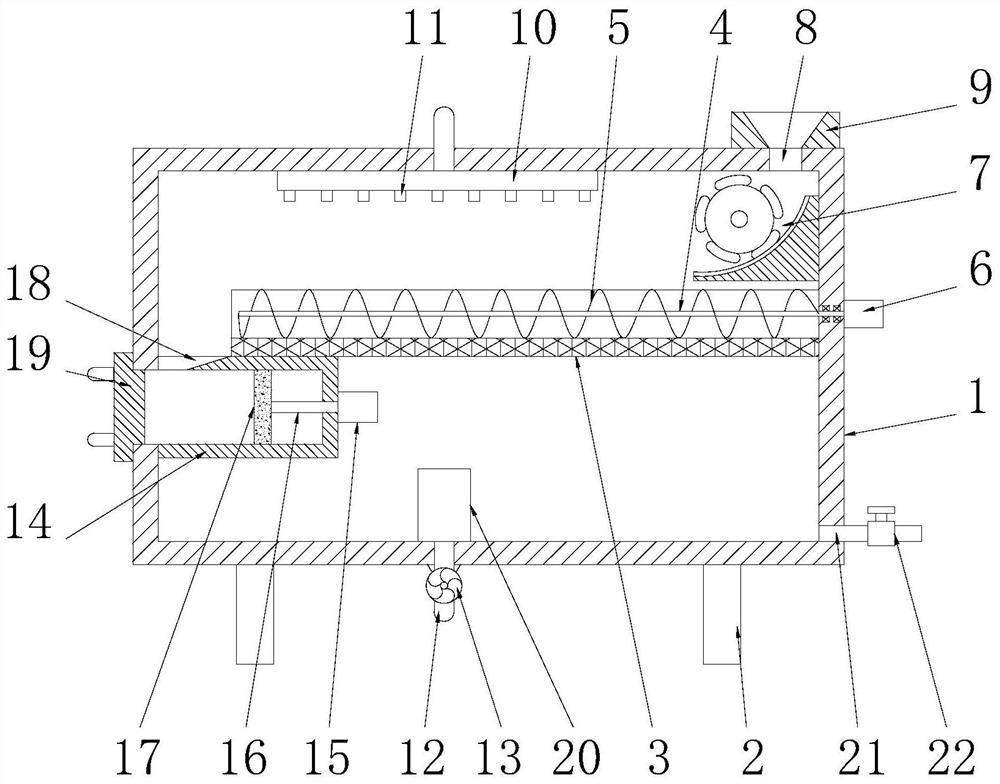

[0024] See figure 1, a medical waste treatment device based on compression crushing treatment technology, including a casing 1, the casing 1 is a cylindrical structure, the bottom of the casing 1 is uniformly provided with a number of legs 2, and the bottom of the casing 1 The middle part of the inner cavity is provided with a transmission grid slot 3, and the end of the transmission grid slot 3 is fixedly connected to the inner cavity wall of the casing 1. The transmission grid slot 3 is made of metal mesh. The cross section of the transmission grid slot 3 It is a semi-circular structure, and a transmission shaft 4 is arranged in the transmission mesh tank 3, the axis of the transmission mesh groove 3 coincides with the axis of the transmission shaft 4, and the end of the transmission shaft 4 penetrates the side wall of the casing 1 and is connected in rotation On the feed motor 6, the transmission shaft 4 is rotatably connected to the casing 1, the feed motor 6 is fixedly in...

Embodiment 2

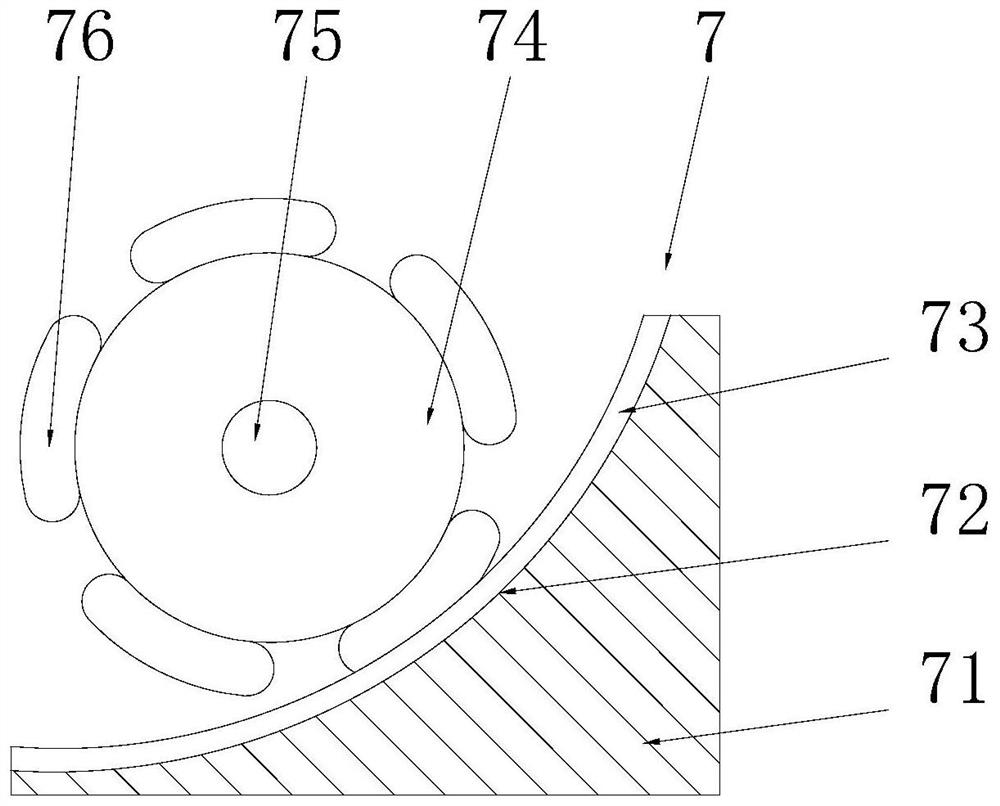

[0028] See figure 2 The difference from Embodiment 1 is that the crushing mechanism 7 includes a crushing seat 71 and a crushing roller 74, the crushing seat 71 is fixedly installed on the inner cavity side wall of the casing 1, and the left end of the crushing seat 71 is provided with There are crushing surfaces 72 matched with the crushing roller 74 and the feeding hole 8 respectively, the crushing surface 72 is an arc surface, and several fixed blades 73 are uniformly arranged on the crushing surface 72, and the fixed blades 73 are arc blades. The crushing roller 74 is arranged on the left side of the crushing surface 72, and the crushing roller 74 is rotatably connected to the casing 1 through the crushing shaft 75, and one end of the crushing shaft 75 penetrates the side wall of the casing 1 and is rotatably connected to the external motor (not shown in the figure), the outer circular surface of the crushing roller 74 is evenly provided with some movable blades 76 that m...

Embodiment 3

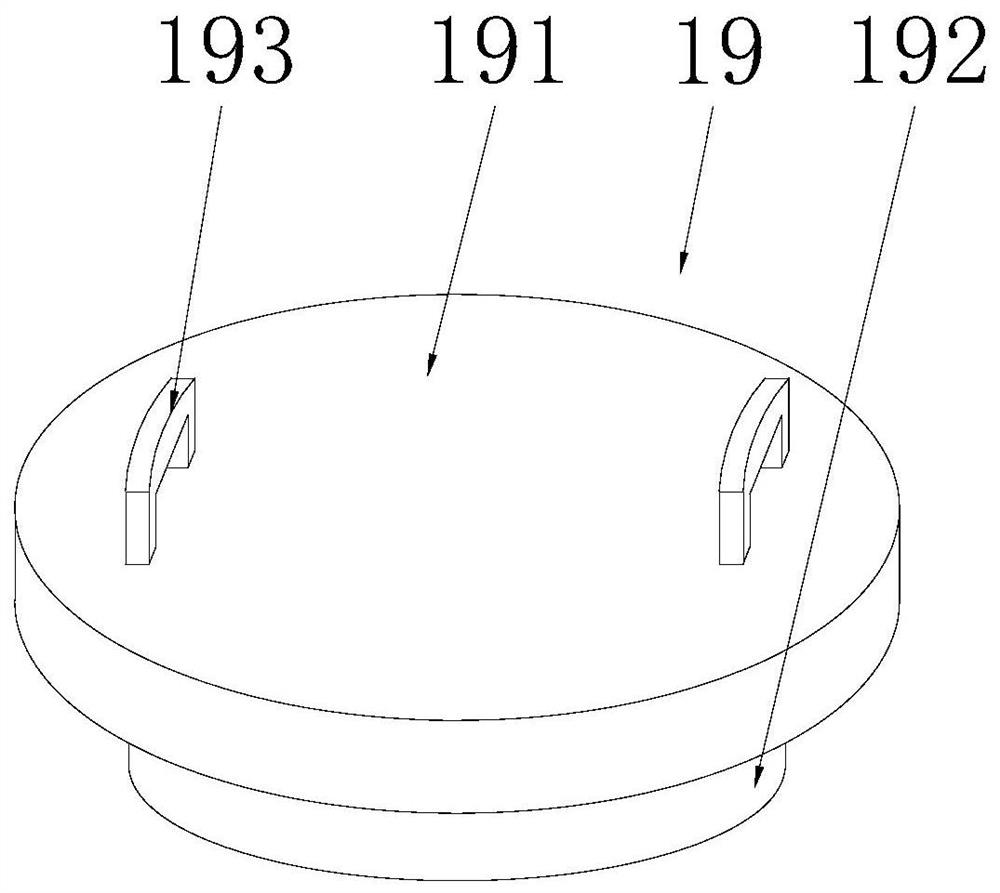

[0030] See image 3 The difference from Embodiment 1 is that the sealing cover 19 includes a cover body 191, the bottom end of the cover body 191 is fixedly connected with a sealing boss 192 matched with the discharge cylinder 14, and the cover body 191 and the sealing boss The posts 192 are integrally formed, and the sealing convex post 192 is screwed to the discharge cylinder 14. The top of the cover body 191 is symmetrically provided with handrails 193. The handrails 193 are U-shaped structures. The handrail 193 rotates the cover 191, and then rotates the sealing boss 192, so that the sealing boss 192 can seal or open the discharge barrel 14, so as to ensure the forming, processing and discharging of medical waste fragments, which can greatly improve the convenience of the whole device application .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com