Large fair-faced mirror surface concrete member and manufacturing method thereof

A technology of fair-faced concrete and a manufacturing method, which is applied in the directions of manufacturing tools and ceramic molding machines, etc., can solve problems such as the limitation of the application range of fair-faced concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

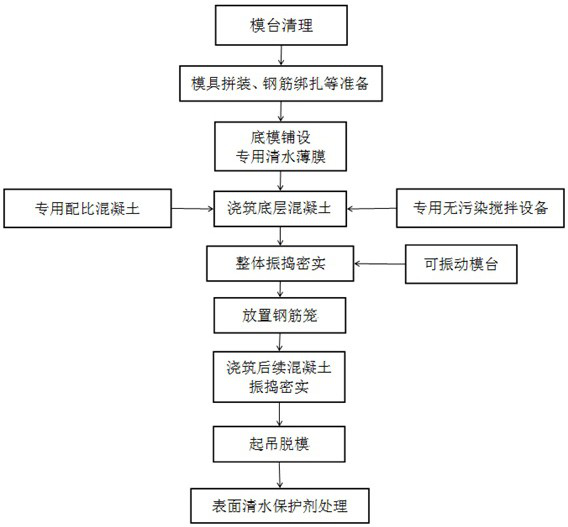

Method used

Image

Examples

Embodiment 1

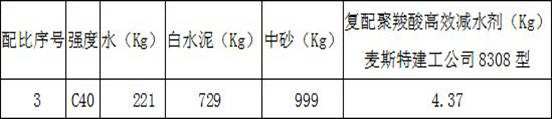

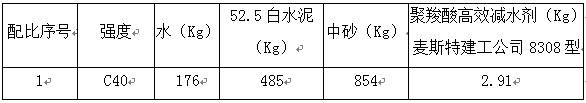

[0030] This embodiment is the pouring method of traditional clear-water mirror concrete components, and its concrete is common clear-water concrete. The formula and proportion of clear-water concrete are shown in Table 1. The mold adopts steel mold and BASF8511 clear-water release agent, and clear-water concrete is stirred by a mixing building. , The vibrating rod is used for vibrating during the pouring process.

[0031] Table 1. Fair-faced concrete mix ratio

[0032]

[0033] The clear-water mirror-finish concrete member formed in Example 1 is observed to have a large color difference in the finish, and there are many air bubbles, the surface of the finish is pitted and the color is dark, and there are residual traces of vibrating rods in the finish.

Embodiment 2

[0035] This embodiment is improved on the basis of Example 1, and the surface of the steel mold is replaced with clear water mold release agent sprayed with clear water formwork paint on the surface of the steel mold. For projects with strict requirements on formwork protection and concrete appearance quality, clear water formwork paint is sprayed on the bottom form. The formula of clear water concrete, the mixing method of clear water concrete and the vibration method in the pouring process are the same as in Example 1.

[0036] The clear-water mirror-finish concrete member formed in Example 2 is observed to have improved color difference compared with Example 1, but there are still uneven color, more air bubbles, and residual traces of vibrating rods.

[0037] Through the comparison of Example 1 and Example 2, it can be obtained that the coating material and flatness on the surface of the bottom mold are the main factors affecting the color difference.

Embodiment 3

[0039] This embodiment is further improved on the basis of Example 2. The steel base mold is coated with clear water formwork paint and replaced with a silica gel base film, and the silica gel film is adhered to the base form. The formula of clear water concrete, the mixing method and pouring of clear water concrete Vibration method in the process is identical with embodiment 1.

[0040] The clear-water mirror concrete member formed in embodiment 3 is observed, and its color difference is bigger than embodiment 1, and is not smooth, and the light and shade of the finishing surface intersects, and there are many air bubbles. Therefore, the silica gel film is not suitable for pouring of clear-water concrete. Through this embodiment, it is considered that the main factors affecting the chromatic aberration of the finish are the flatness and surface tension of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com