Thick coating type PE clear primer

A clear primer and thick coating technology, applied in the field of wood primer, which can solve the problems of easy cracking, slow drying speed and general adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

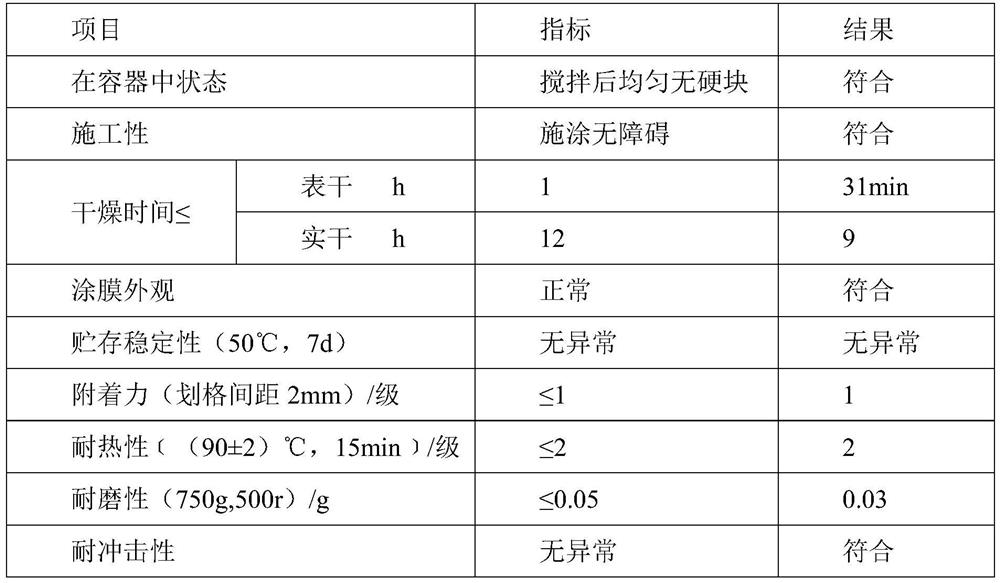

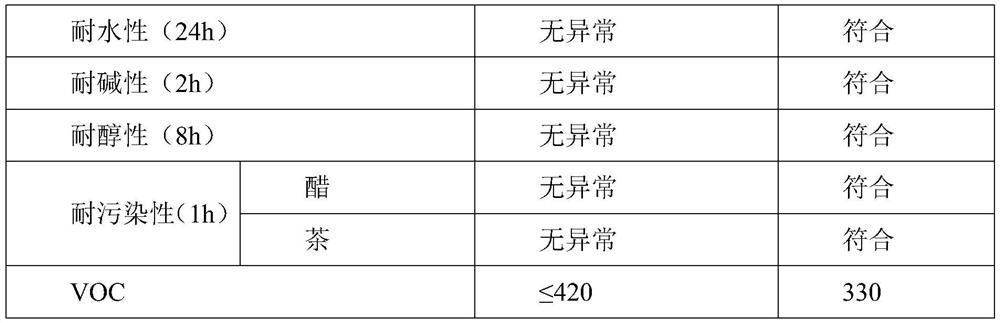

Examples

preparation example Construction

[0022] The preparation method of the first component of the embodiment of the present invention is as follows:

[0023] Step 1: Mix unsaturated polyester resin, polyether resin, and dispersant, and disperse at a medium speed for 10-15 minutes until fully uniform, ensuring that the viscosity is 10000±500CPS / 25°C;

[0024] Step 2: Add filler to the solution obtained in Step 1, and disperse evenly;

[0025] Step 3: Add defoamer, leveling agent, anti-greening agent, 3-5 parts by weight of unsaturated solvent to the mixture obtained in step 2, and disperse evenly;

[0026] Step 4: Add the remaining unsaturated solvent to the mixture obtained in Step 3, and disperse until the fineness is ≤50um, and the viscosity is controlled at 10000±500CPS / 25°C.

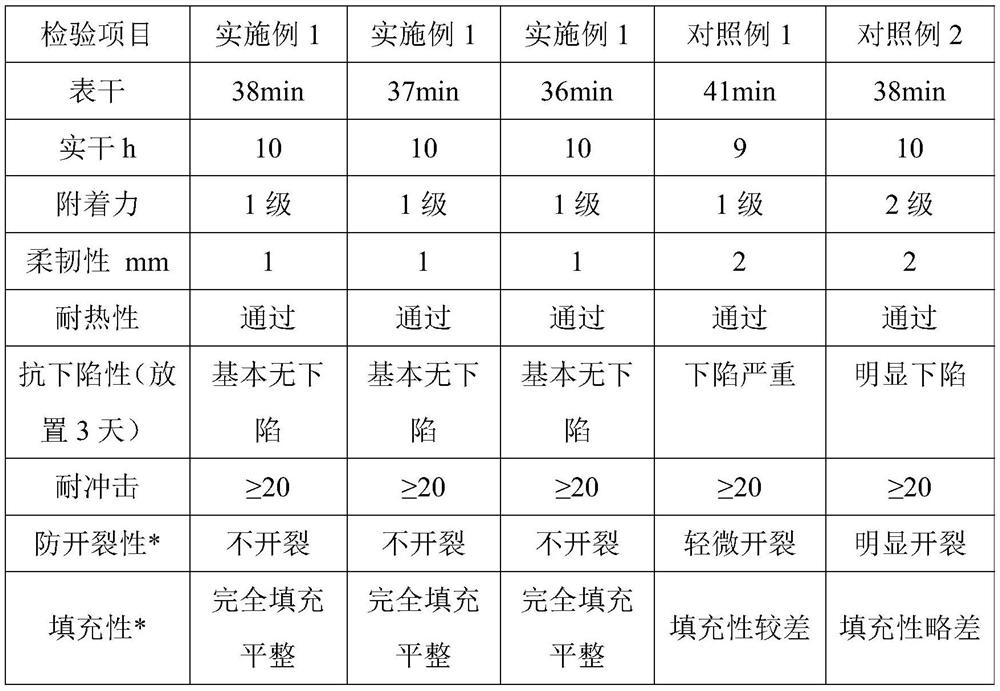

Embodiment 1

[0028] Component A of the embodiment of the present invention consists of 65 parts by weight of unsaturated polyester resin, 2 parts by weight of polyether resin, 0.2 parts by weight of dispersant, 15 parts by weight of transparent powder, 3 parts by weight of talcum powder, 0.3 parts by weight of The antifoaming agent of 0.3 weight part, the leveling agent of 0.1 weight part, the anti-greening agent of 0.1 weight part, the unsaturated solvent composition of 3 weight parts;

[0029] Component B consists of 40 parts by weight of ethyl acetate, 25 parts by weight of dimethyl carbonate, and 35 parts by weight of styrene.

Embodiment 2

[0031] Component A of the embodiment of the present invention consists of 75 parts by weight of unsaturated polyester resin, 3 parts by weight of polyether resin, 0.3 parts by weight of dispersant, 20 parts by weight of transparent powder, 5 parts by weight of talcum powder, 0.5 parts by weight of The defoamer, the leveling agent of 0.5 weight part, the anti-greening agent of 0.2 weight part, the unsaturated solvent composition of 5 weight parts;

[0032] Component B consists of 45 parts by weight of ethyl acetate, 30 parts by weight of dimethyl carbonate, and 40 parts by weight of styrene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com