High-hardness super-wear-resistant two-component waterborne polyurethane terrace coating

A water-based polyurethane and floor coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of poor physical properties, oil-based product performance and service life are on a par, wear resistance and scratch resistance are not consistent, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

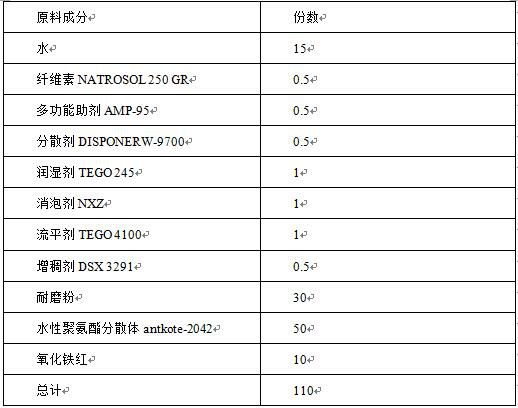

[0045] A kind of high hardness super wear-resisting two-component waterborne polyurethane floor coating of the present embodiment comprises the raw material of following parts by weight:

[0046] A component:

[0047]

[0048] The wear-resistant powder is a combination of 40% white corundum, 25% glass powder, 30% nano-quartz powder and 5% wax powder.

[0049] According to the above ratio, disperse the component A material at a high speed to a fineness of less than 50 microns, mix it evenly and put it in a bucket for use.

[0050] B component:

[0051] aquolin-270.

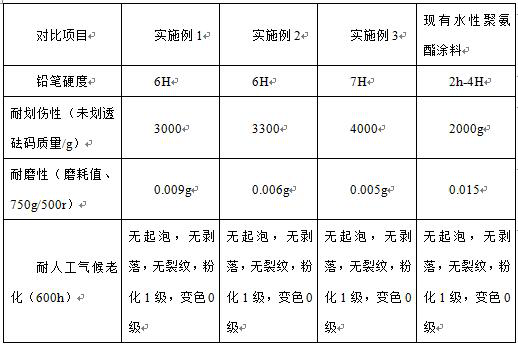

[0052]When in use, mix component A and component B with a mass ratio of 3:1 through mechanical stirring, add 15% deionized water to dilute, and evenly coat the tinplate sheet and the non-asbestos fiber cement board by roller coating Product samples were obtained. The performance indicators of the tested products are shown in Table 1.

Embodiment 2

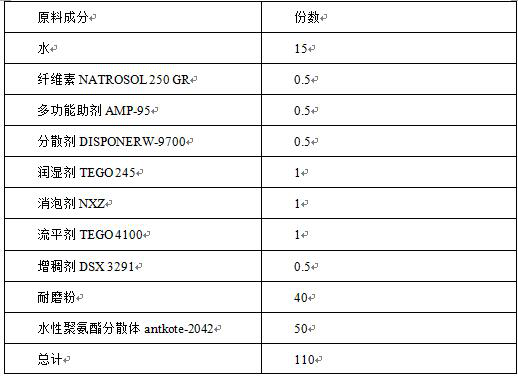

[0054] A kind of high hardness super wear-resisting two-component waterborne polyurethane floor coating of the present embodiment comprises the raw material of following parts by weight:

[0055] A component:

[0056]

[0057] The wear-resistant powder is a combination of 40% white corundum, 25% glass powder, 30% nano-quartz powder and 5% wax powder.

[0058] According to the above ratio, disperse the component A material at a high speed to a fineness of less than 50 microns, mix it evenly and put it in a bucket for use.

[0059] B component:

[0060] Waterborne polyurethane curing agent.

[0061] When in use, mix component A and component B with a mass ratio of 5:1 through mechanical stirring, add 15% deionized water to dilute, and evenly coat the tinplate sheet and asbestos-free fiber cement board by rolling Product samples were obtained. The performance indicators of the tested products are shown in Table 1.

Embodiment 3

[0063] A kind of high hardness super wear-resisting two-component waterborne polyurethane floor coating of the present embodiment comprises the raw material of following parts by weight:

[0064] A component:

[0065]

[0066] The wear-resistant powder is a combination of 40% white corundum, 25% glass powder, 30% nano-quartz powder and 5% wax powder.

[0067] According to the above ratio, disperse the component A material at a high speed to a fineness of less than 50 microns, mix it evenly and put it in a bucket for use.

[0068] B component:

[0069] Waterborne polyurethane curing agent.

[0070] When in use, mix component A and component B with a mass ratio of 4:1 through mechanical stirring, add 15% deionized water to dilute, and evenly coat the tinplate sheet and non-asbestos fiber cement board by roller coating Product samples were obtained. The performance indicators of the tested products are shown in Table 1.

[0071] Table 1: The basic performance index table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com