Method for recycling waste mercury sulfate reagent

A recovery method and waste sulfuric acid technology, applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high cost and complicated mercury sulfate treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

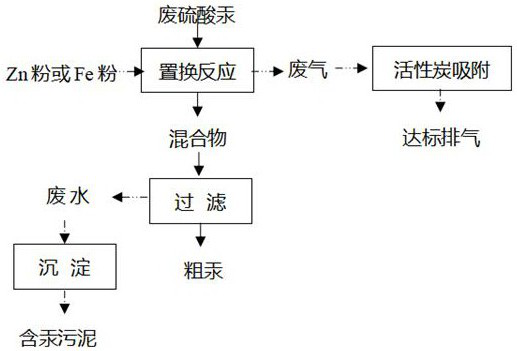

Image

Examples

Embodiment 1

[0018] Take 5g of waste mercuric sulfate reagent and add it to 1L of deionized water (temperature 80°C), stir to dissolve, then move it into a 2L reaction kettle, add 2.5g of Zn powder to it, stir evenly, and react at a controlled temperature of 50°C for 0.2h.

[0019] Cool to room temperature at the end of the reaction to generate metal crude Hg and ZnSO 4 solution, the metal crude Hg is filtered and purified to obtain the elemental mercury product, and the purity of mercury is 98.42% after testing.

Embodiment 2

[0021] Take 5g of waste mercuric sulfate reagent and add it to 1L of deionized water (temperature 80°C), stir to dissolve, then move it into a 2L reaction kettle, add 2.5g of Fe powder to it, stir evenly, and react for 0.2h at a controlled temperature of 50°C.

[0022] Cool to room temperature at the end of the reaction to generate metal crude Hg and FeSO 4 solution, the crude metal Hg is filtered and purified to obtain the elemental mercury product, and the purity of mercury is 97.78% after testing.

Embodiment 3

[0024] Take 5g of waste mercuric sulfate reagent and add it to 1L of deionized water (temperature 80°C), stir to dissolve, then move it into a 2L reactor, add 4g of Zn powder to it, stir evenly, and react at a controlled temperature of 80°C for 0.5h.

[0025] Cool to room temperature at the end of the reaction to generate metal crude Hg and ZnSO 4 solution, the metal crude Hg is filtered and purified to obtain the elemental mercury product, and the purity of mercury is 98.73% after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com