Moisture-absorbing loop pile polyester carpet and manufacturing method thereof

A carpet and polyester technology, applied in the field of moisture-absorbing loop pile polyester carpet and its preparation, can solve the problems of low tensile strength, pile shedding, and high frequency of yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

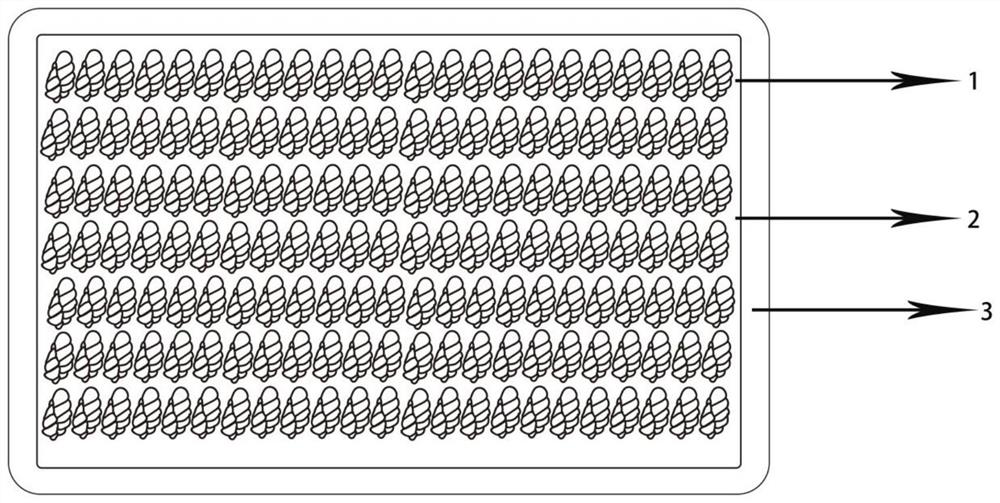

[0041] This example involves a kind of hygroscopic loop pile polyester carpet, such as figure 1 shown, including:

[0042] Blanket surface layer 1: pile structure, with Z-twisted yarn tufts processed by plying and threading polyester filament fibers, implanted into the base fabric layer to form a plurality of twist-like protrusions;

[0043] Base fabric layer 2: network silk base fabric;

[0044] Anti-slip layer 3: the bottom styrofoam anti-slip and water-repellent layer.

[0045] The preparation of this moisture-absorbing loop pile polyester carpet comprises the steps:

[0046] 1) Spinning: 40 pieces of 150D DTY polyester filaments are used to ply to form a 6000D ply yarn; a two-for-one twister is used to twist the yarn, and the yarn is Z twist. The twist is 96T / m.

[0047] Weaving: Tufted weaving adopts S-twist tufting loom, the yarn is reversely penetrated into the tufting machine needle to tuft on the base fabric layer, and the yarn is driven by the needle to pierce th...

Embodiment 2

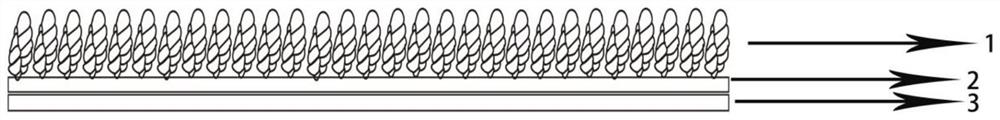

[0052] This example involves a kind of hygroscopic loop pile polyester carpet, such as figure 2shown, including:

[0053] Blanket surface layer 1: pile structure, with Z-twisted yarn tufts processed by plying and threading polyester filament fibers, implanted into the base fabric layer to form a plurality of twist-like protrusions;

[0054] Base fabric layer 2: network silk base fabric;

[0055] Anti-slip layer 3: The bottom TPE anti-slip and water-repellent layer.

[0056] The preparation of this imitation cotton polyester water-absorbing carpet comprises the steps:

[0057] 1) Spinning: 32 DTY polyester filaments of 300D are used to ply into 9600D ply yarn, and the yarn is twisted by a two-for-one twister, and the yarn is Z twist. The twist is 50T / m.

[0058] 2) Dyeing: Put the yarn into the dyeing vat for dyeing.

[0059] 3) Weaving: S twist tufting loom is used for tufting weaving. The dyed yarn is reversely penetrated into the tufting machine needle to tuft on the b...

Embodiment 3

[0064] This example involves a kind of hygroscopic loop pile polyester carpet, including:

[0065] Blanket surface layer: pile structure, with Z-twisted yarn tufts processed by plying and threading polyester filament fibers, implanted into the base fabric layer to form multiple twist-shaped protrusions by self-twisting;

[0066] Base fabric layer: PP needle-punched non-woven fabric;

[0067] Anti-Slip Layer: Bottom layer of non-slip, water-repellent fabric.

[0068] The preparation of this moisture-absorbing loop pile polyester carpet comprises the steps:

[0069] 1) Spinning: 42 ATY polyester 200D filaments are used to ply into 8400D ply yarn; two-for-one twister is used to twist the yarn, and the yarn is Z twist. The twist is 60T / m.

[0070] Weaving: Tufted weaving adopts S-twist tufting loom, the yarn is reversely penetrated into the tufting machine needle to tuft on the base fabric layer, and the yarn is driven by the needle to pierce through the base fabric layer , in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com