Treatment method of wet curtain paper broke

A processing method, technology of wet curtain paper, applied in fiber raw material processing, paper, papermaking, etc., can solve the problems of high wet strength requirements, long processing time, waste of fiber raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

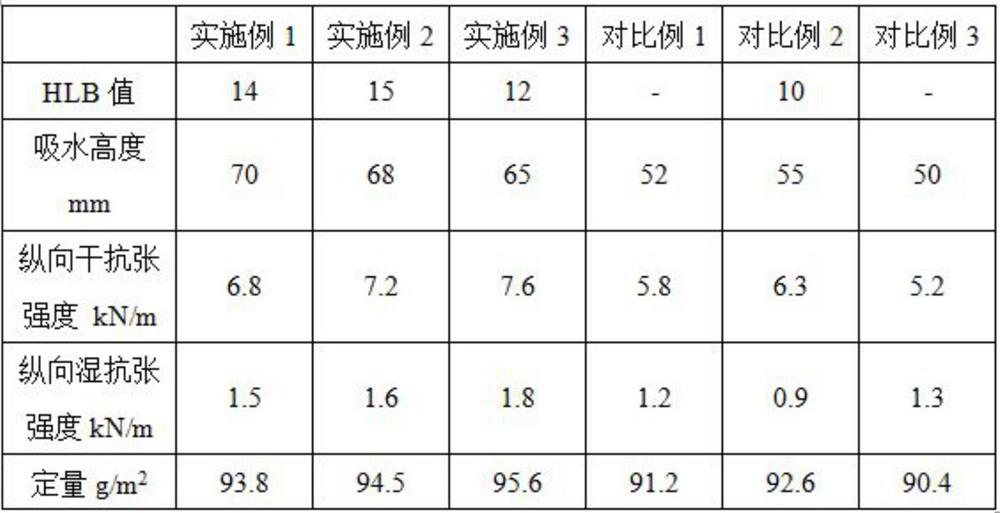

Examples

Embodiment 1

[0025] A method for processing damaged wet curtain paper, comprising the following steps:

[0026] Step 1: Evenly put the broken paper and waste paper produced during production into the pulper, add water, turn on the steam valve and heat to 82°C for preliminary disintegration to obtain pulp. The disintegration time is 2.5 hours. The concentration is 4.3%;

[0027] Step 2: Send the slurry obtained after the treatment in step 1 to the slurry storage tank, and pump it to a disc refiner for slight disintegration until the slurry is completely disintegrated;

[0028] Step 3: Send the slurry treated in step 2 to a beater, then add nonylphenol polyoxyethylene ether and naphthenate, the beating concentration is 6%, the beating degree is 35°SR, and the nonylphenol polyoxyethylene ether and naphthenate are added. The added mass of phenolic polyoxyethylene ether accounts for 2% of the total mass of the slurry; the added mass of the naphthenate accounts for 1.0% of the total mass of the...

Embodiment 2

[0031] A method for processing damaged wet curtain paper, comprising the following steps:

[0032] Step 1: Evenly put the broken paper and waste paper produced during production into the pulper, add water, open the steam valve and heat to 80°C for preliminary disintegration to obtain pulp. The disintegration time is 2 hours and the pulp concentration 5%;

[0033] Step 2: Send the slurry obtained after the treatment in step 1 to the slurry storage tank, and pump it to a disc refiner for slight disintegration until the slurry is completely disintegrated;

[0034] Step 3: Send the slurry treated in step 2 to a beater, then add nonylphenol polyoxyethylene ether and naphthenate, the beating concentration is 8%, the beating degree of beating is 38°SR, and the nonylphenol polyoxyethylene ether and naphthenate are added. The added mass of phenolic polyoxyethylene ether accounts for 5% of the total mass of the slurry; the added mass of the naphthenate accounts for 0.5% of the total ma...

Embodiment 3

[0037] A method for processing damaged wet curtain paper, comprising the following steps:

[0038] Step 1: Evenly put the broken paper and waste paper produced during production into the pulper, add water, open the steam valve and heat to 85°C for preliminary disintegration to obtain pulp. The disintegration time is 2.2 hours. The concentration is 4%;

[0039] Step 2: Send the slurry obtained after the treatment in step 1 to the slurry storage tank, and pump it to a disc refiner for slight disintegration until the slurry is completely disintegrated;

[0040] Step 3: Send the slurry treated in step 2 to a beater, then add nonylphenol polyoxyethylene ether and naphthenate, the beating concentration is 7%, the beating degree of beating is 36°SR, and the nonylphenol polyoxyethylene ether and naphthenate are added. The added mass of phenol polyoxyethylene ether accounts for 4% of the total mass of the slurry; the added mass of the naphthenate accounts for 0.8% of the total mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com