Inspection and detection method for organic matter content in soil

A technology of organic matter content and detection method, which is applied in chemical analysis by titration, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., which can solve the trouble of operation and difficult temperature of electric furnace control, inability to achieve complete oxidation of organic matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

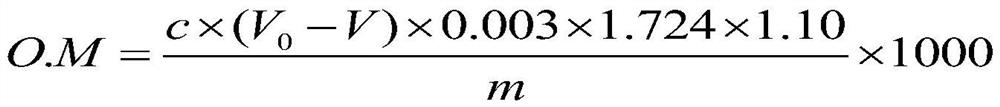

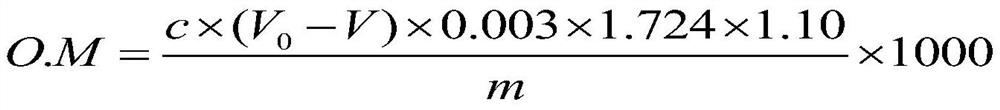

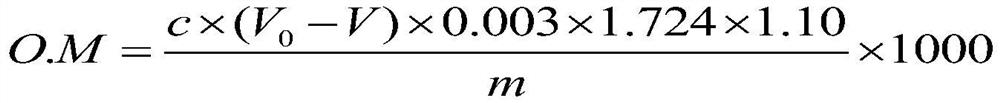

[0054] Weigh 0.3368g, 0.3416g, 0.2705g (accurate to 0.0001) of 100 mesh air-dried soil samples into three glass conical flasks, then add 10.00ml 0.4mol / L potassium dichromate-sulfuric acid solution, shake well and Insert a glass funnel into each flask. Put all the triangular flasks in the iron reagent tray, heat the oven to a constant temperature of 120°C in advance, put the tray with samples in the oven and bake at 120°C for 2 hours, shake once in the middle, and take the tray out of the oven after 2 hours Take it out, cool it for a while, rinse the small funnel with water directly, wash the lotion into the Erlenmeyer flask, control the total volume of the solution in the Erlenmeyer flask at 50mL~60mL, add 3 drops of o-phenanthroline indicator, and use ferrous sulfate standard solution Titrate the remaining K 2 Cr 2 o 7 , The discoloration process of the solution is orange-yellow-blue-green-brown red.

Embodiment 2

[0056] Using the NY / T 1121.6-2006 method, weigh 0.3368g, 0.3416g, and 0.2705g (accurate to 0.0001) of 100-mesh air-dried soil samples into three hard test tubes, and then add 10.00ml 0.4mol / L to the triangular flask Potassium dichromate-sulfuric acid solution, shake well and insert a glass funnel into each test tube mouth. Insert the test tubes into the wire cage one by one, and then sink the wire cage into the oil bath pot heated to 185℃~190℃ on the electric furnace, so that the liquid level in the tube is lower than the oil level, and the temperature of the oil bath should drop after putting it in. To 170°C-180°C, start timing when the solution in the test tube boils. At this moment, the temperature of the electric furnace must be controlled to prevent the solution from boiling violently. During this period, the wire cage can be gently lifted and shaken in the oil bath for several times to make the liquid temperature uniform. , and maintained at 170°C to 180°C, after 4.5min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com