Solid-core polarization-maintaining cut-off-free single-mode microstructure optical fiber and preparation process thereof

A technology of microstructured optical fiber and preparation process, which is applied in the direction of multi-layer core/clad optical fiber, manufacturing tools, clad optical fiber, etc., which can solve the problems of difficulty in optical fiber preparation, no solution, and difficulty in maintaining the microstructure of optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

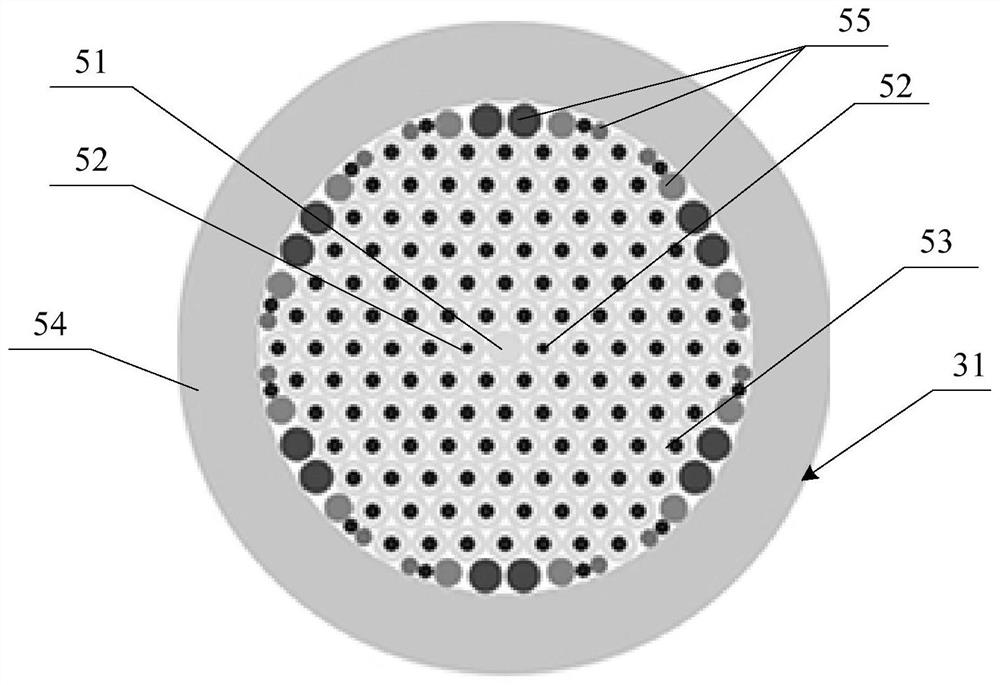

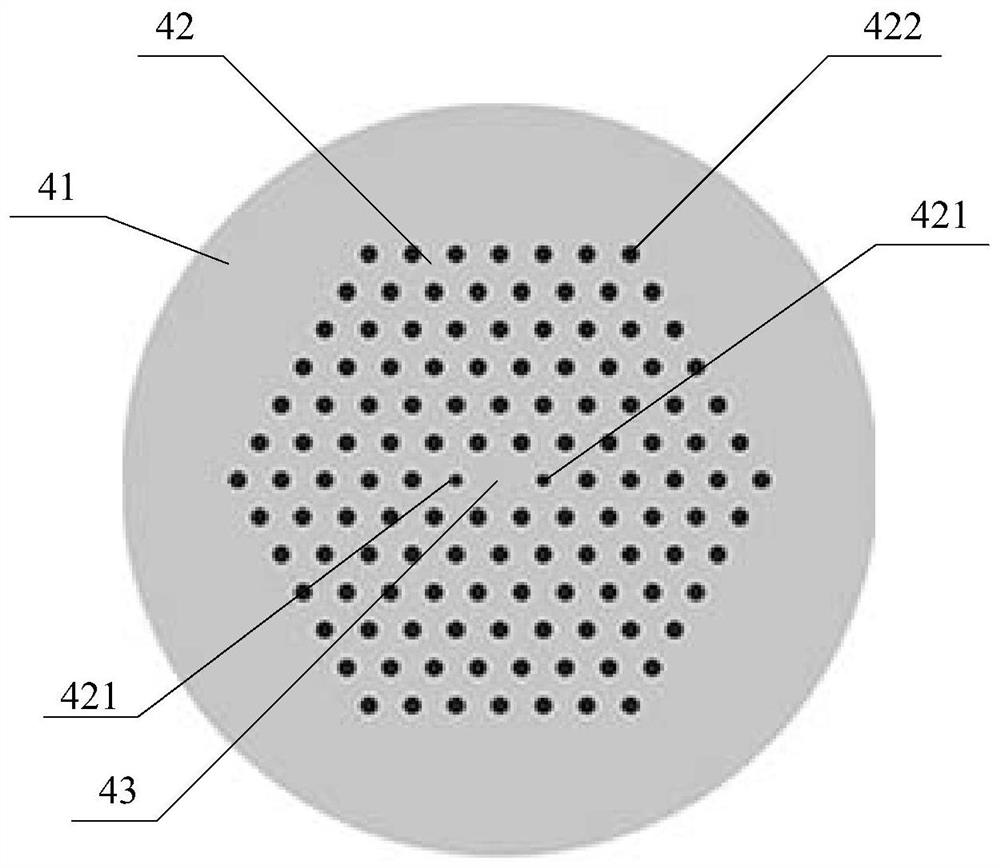

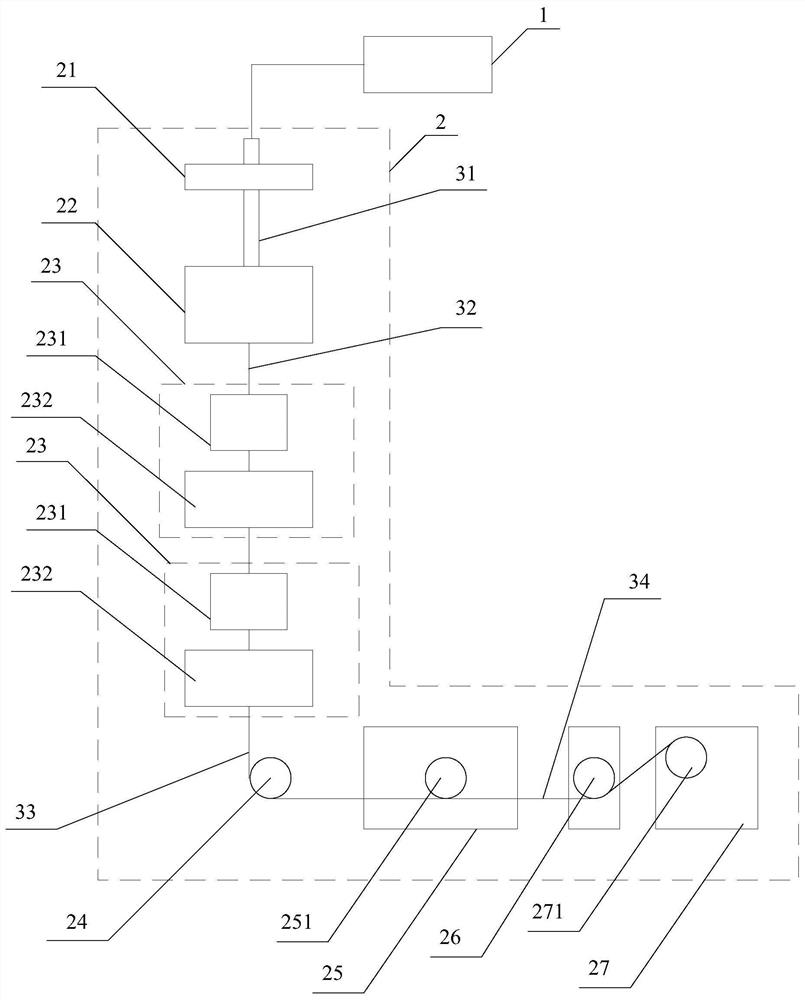

[0045] The preparation process of a solid-core polarization-maintaining non-cut-off single-mode microstructure optical fiber proposed in this embodiment, according to Figure 1a As shown, from the inside to the outside close to stack six circles of quartz capillary, the first quartz capillary 52 is Figure 1a Two quartz capillaries distributed symmetrically in the lateral direction in the innermost quartz capillary, that is, the number of the first quartz capillary 52 is 2, and the number of the second quartz capillary 53 is 124; after the stack is formed, the optical fiber prefabricated Rod 31; the optical fiber preform rod 31 is drawn into optical fiber, and the two first quartz capillaries 52 are independently controlled by partial pressure during the process of drawing the optical fiber. , the number of air holes included in the inner cladding is 126, the ratio of the aperture of the first air hole 421 to the aperture of the second air hole 422 is 0.75, and the ratio between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com