Gas transfer type anti-freezing and high-temperature-resistant cable

A transferable, high-temperature-resistant technology, applied in the direction of insulated cables, power cables, and power cables with shielding layers/conductive layers, etc., can solve problems that affect the efficiency of cable use, low power transmission speed, and power transmission efficiency that is easily affected by external temperatures Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

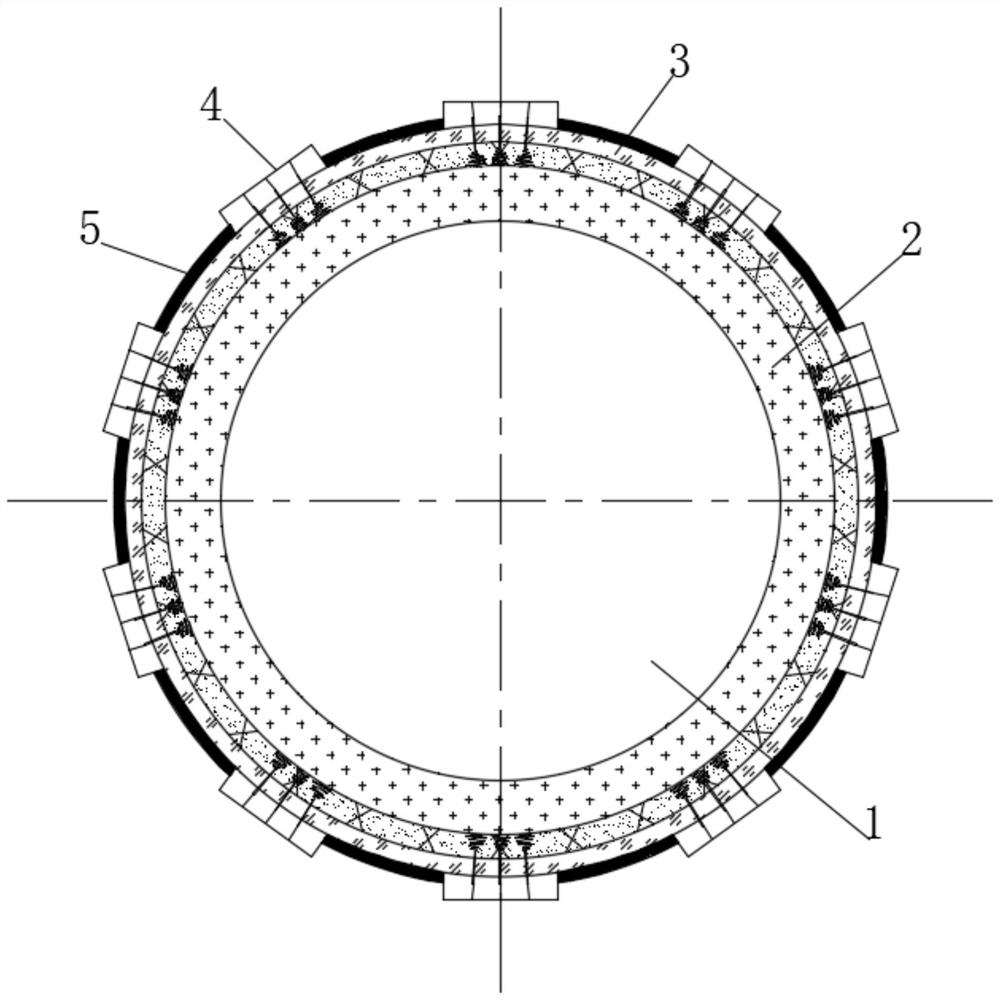

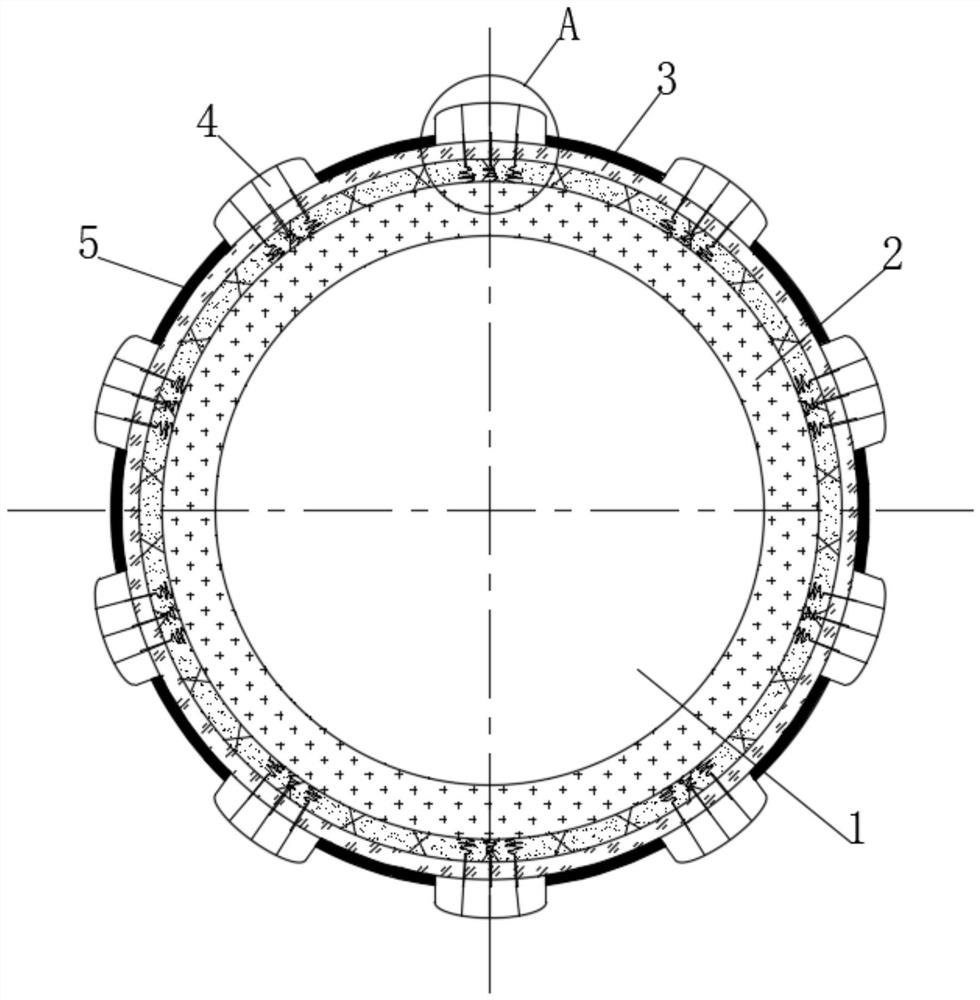

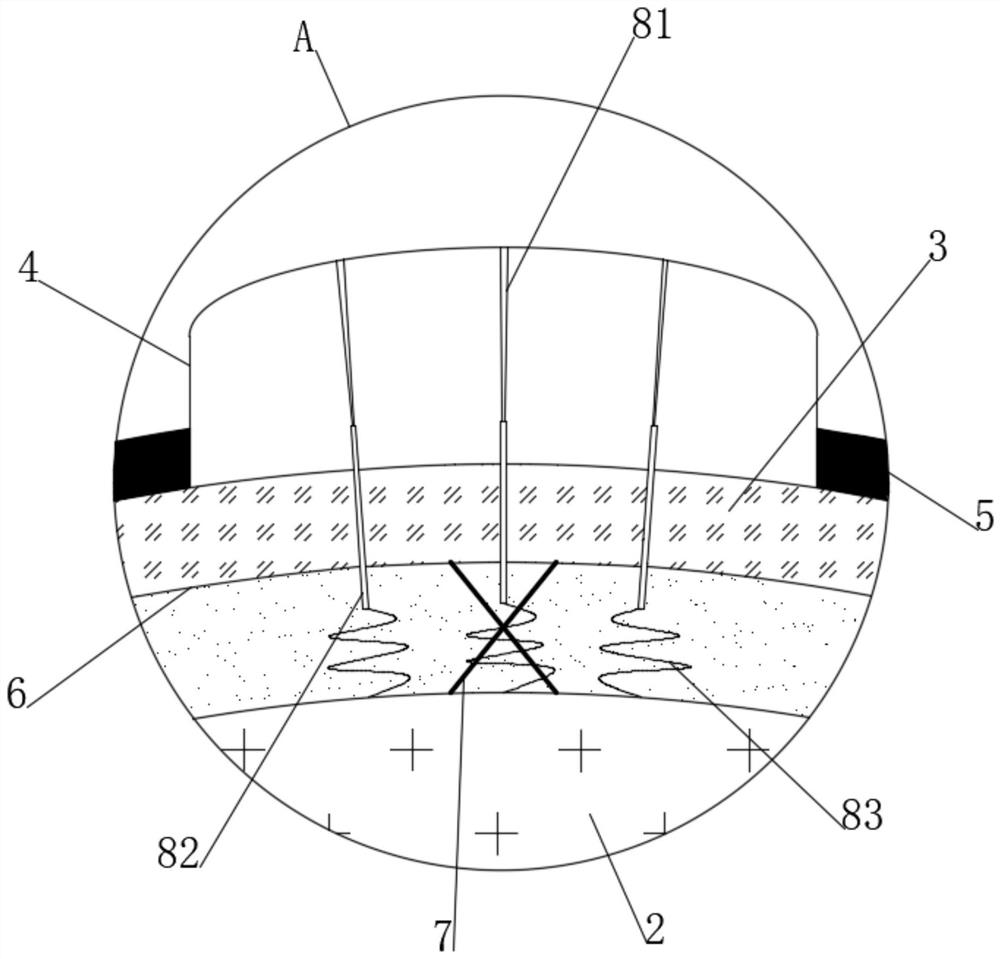

[0036] see figure 1 , a gas transfer type antifreeze and high temperature resistant cable, including a core layer 1, the outer end of the core layer 1 is wrapped with a cable sheath, and the cable sheath includes an inner sheath 2 and an outer sheath 3 and is connected to the inner sheath 2 and the flexible interlayer 6 between the outer sheath 3, the outer end of the outer sheath 3 is fixedly connected with a plurality of evenly distributed self-bulging cladding layers 4 and temperature-insulating layers 5, and a plurality of self-bulging cladding layers 4 and temperature-insulating layers 5 are alternately distributed and touch each other.

[0037] see image 3 , the flexible interlayer 6 includes a plurality of low-condensation heat insulation nets 7 connected between the inner sheath 2 and the outer sheath 3 and interlayer protective gas filled between the inner sheath 2 and the outer sheath 3, the interlayer protective gas is A gas with poor thermal conductivity, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com