Preparation method of pyroelectric sensitive element

A pyroelectric and sensitive technology, which is applied to thermoelectric devices with thermal changes in dielectric constant, electrical radiation detectors, etc. It can solve the problems of low film firmness, fewer production processes, and difficulty in patterning, and achieve good electrical conductivity. properties, chemical stability, improved absorption efficiency, and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

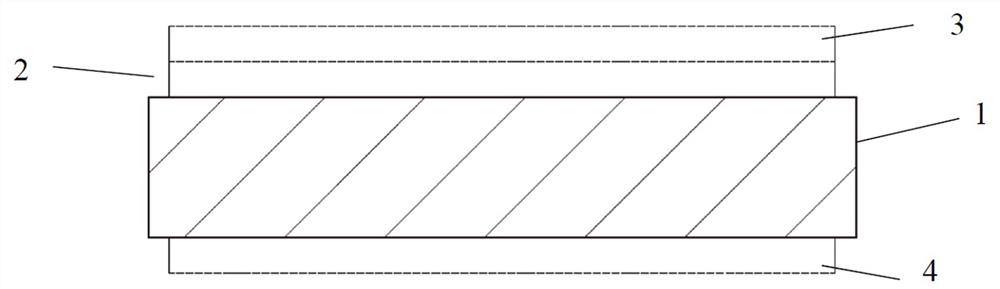

[0034] Such as figure 1 Shown is a specific embodiment of the pyroelectric sensing element provided by the present invention, wherein the pyroelectric sensing element has a pyroelectric crystal 1, and the upper side of the pyroelectric crystal 1 is sequentially provided with an upper electrode 2 and an absorbing layer 3, the lower side of the pyroelectric crystal 1 is provided with a lower electrode 4, and both the upper electrode 2 and the lower electrode 4 have a double-layer structure, and the double-layer structure includes a nickel-chromium alloy layer and A gold layer, the nickel-chromium alloy layer is arranged close to the pyroelectric crystal 1 .

[0035] For the absorbing layer, preferably a gold black layer, that is, a blackened gold film; the pyroelectric crystal can be selected from lithium tantalate (LiTaO 3 ) crystals, genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com