Lithium ion battery positive plate, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive plates, applied in battery electrodes, non-aqueous electrolyte battery electrodes, positive electrodes, etc., can solve the problem of reducing the energy density of the battery cell, uneven distribution of the current density, and lithium separation at the edge of the battery cell and the ear. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

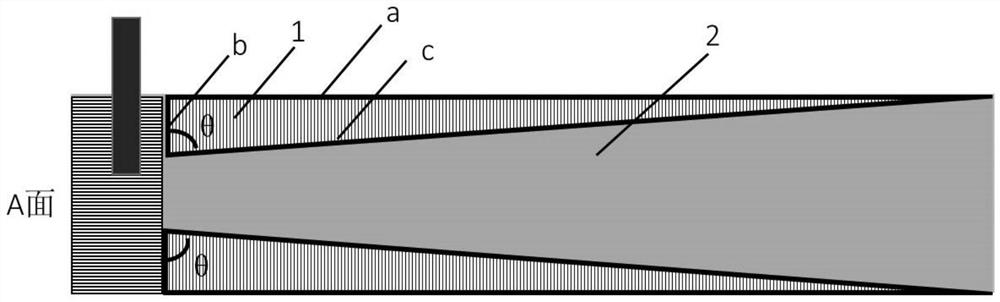

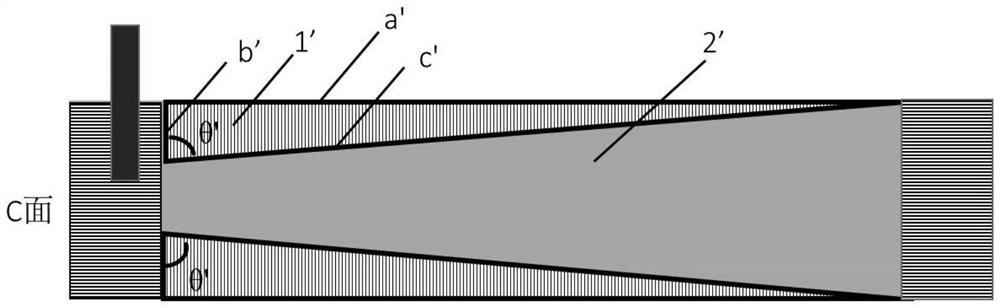

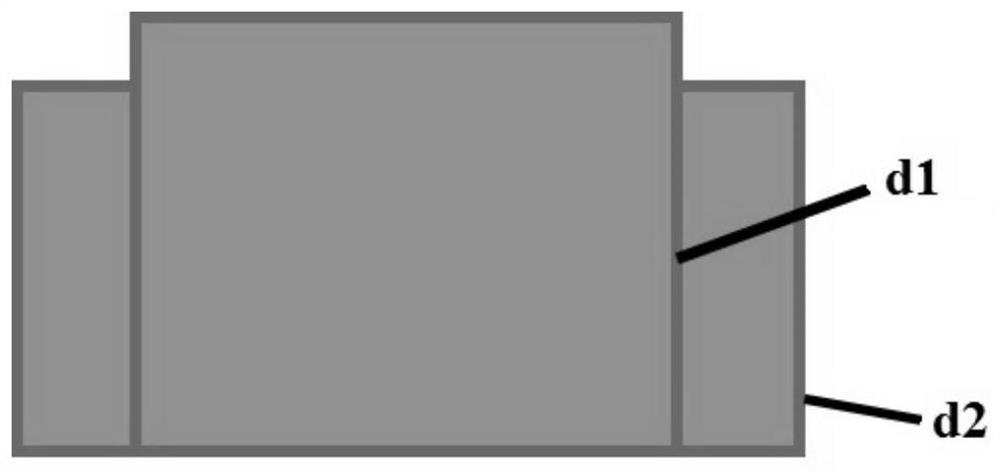

[0039] The present embodiment provides a kind of lithium-ion battery positive plate, such as Figure 1-Figure 3 As shown, the active material layer is coated on the A surface and the C surface (that is, the front and back surfaces) of the current collector. It consists of an unthinned area 2 connected to the thinned area 1 (located between the thinned areas at the edges of both sides), and the areal density of the active material in the thinned area 1 is less than that of the active material in the un-thinned area 2; The thin area 1 gradually widens along the length direction of the current collector, and its widest point is located at the end of the current collector close to the tab.

[0040] Wherein, the widths of the active material layers of the A surface and the C surface are both L5, and the width of the widest part of the thinned area is L2, L2 / L5=0.05; the surface density of the active material in the non-thinned area 2 is ρ1, reduced The surface density of the activ...

Embodiment 2

[0045] The difference between the positive electrode sheet and its preparation method and the lithium ion battery provided in this example and that of Example 1 is that L2 / L5=0.1 is controlled; other conditions are the same as those of Example 1.

Embodiment 3

[0047] The difference between the positive electrode sheet and its preparation method and the lithium ion battery provided in this example and that of Example 1 is that ρ2 / ρ1=0.9 is controlled; other conditions are the same as those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com