High-precision mechatronics control equipment

A control equipment, high-precision technology, applied in the direction of electrical equipment construction parts, electrical components, chemical instruments and methods, etc., can solve the problem of affecting the service life of mechatronic control devices, dust entering the computer, and affecting mechatronic control devices Normal use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

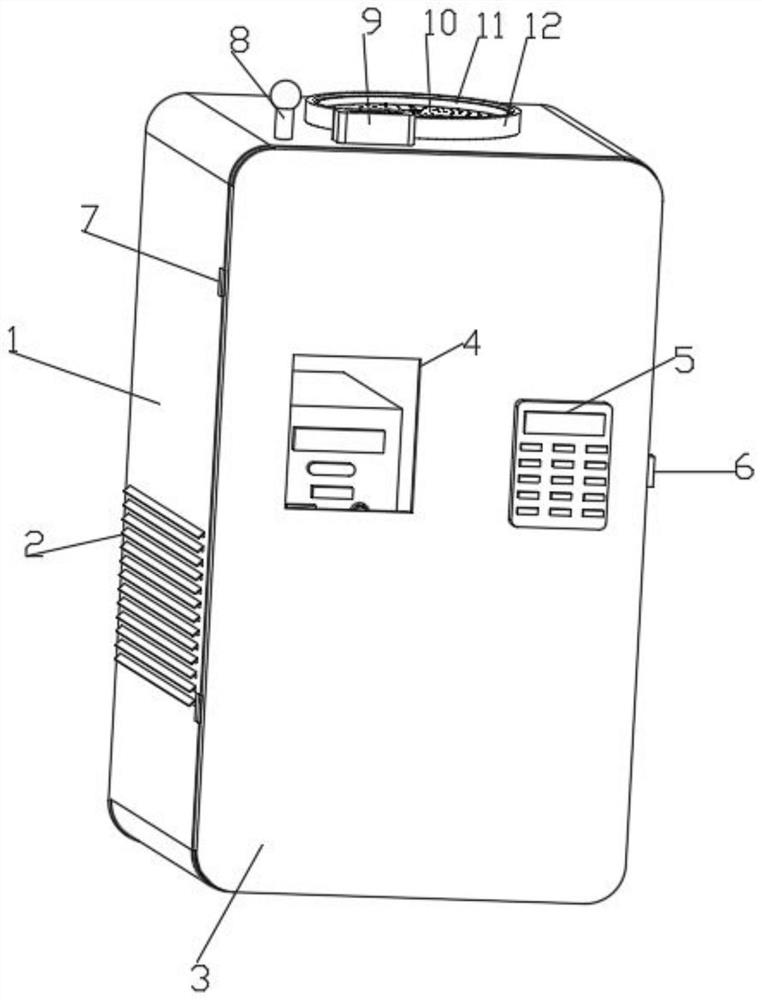

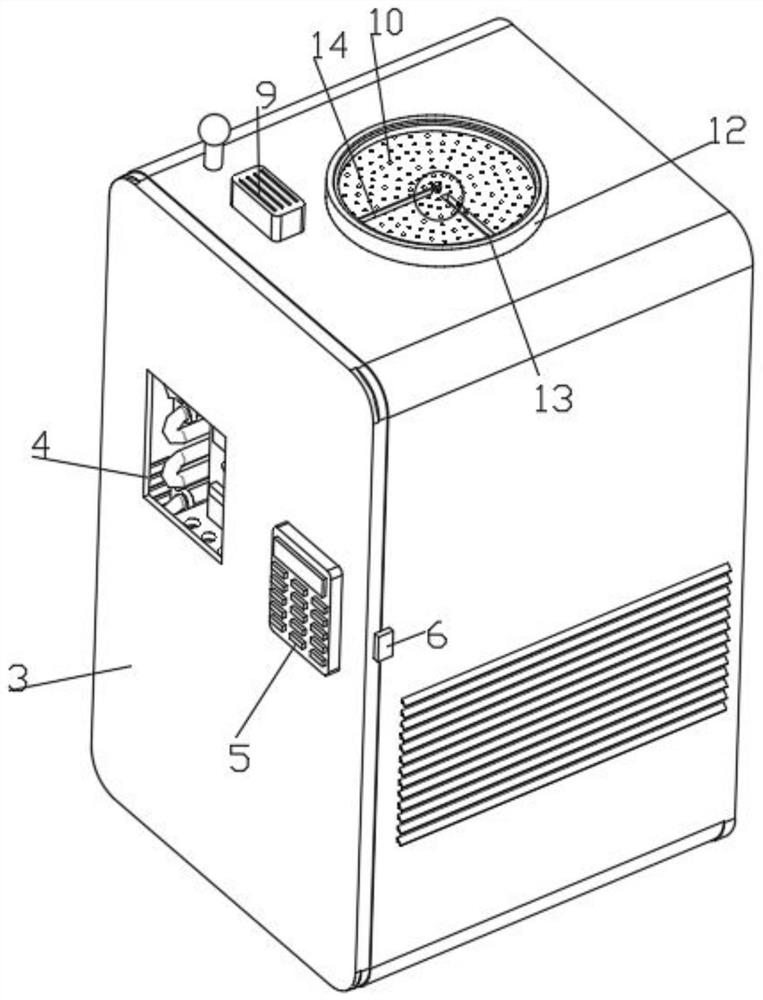

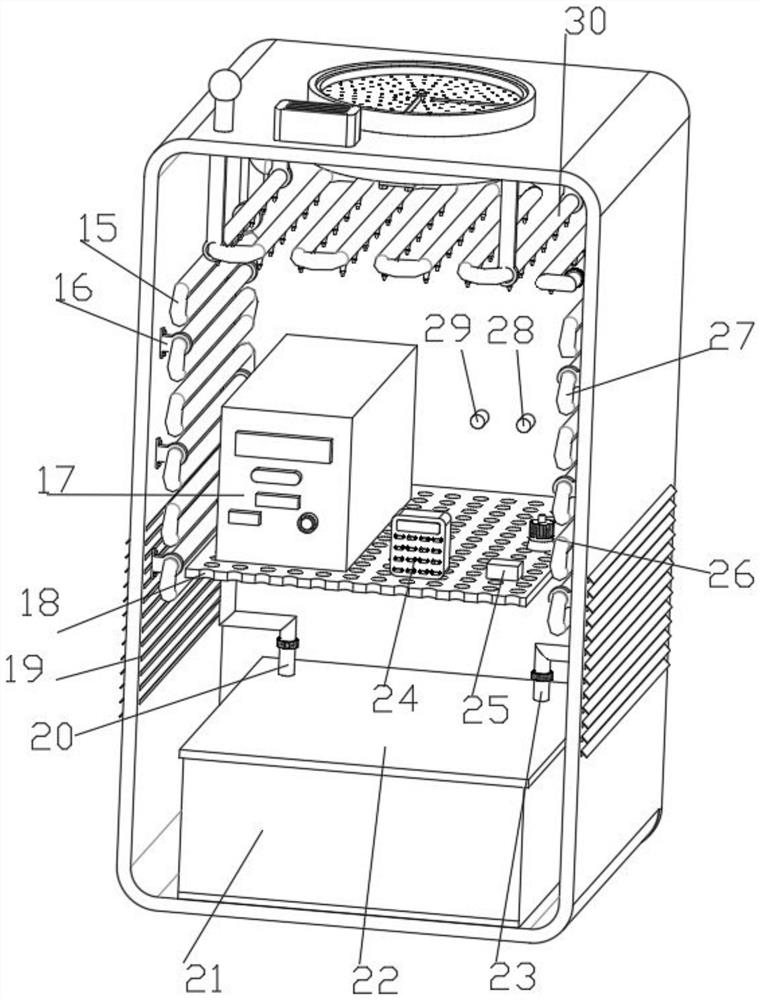

[0037] Such as Figure 1-8A high-precision electromechanical integrated control device is shown, including a box body 1, a first controller 5, an alarm lamp 8, a speaker 9, a control device 17, a second controller 24, an air switch 25, an automatic release button 26, a temperature Inductor 28, smoke sensor 29, driving motor 35 and water pump 36, the front side wall of box body 1 is connected with door panel 3, and the first controller 5 is fixedly installed on door panel 3, and the top of box body 1 is fixedly connected with alarm lamp 8, Loudspeaker 9 and air intake pipe 12, the middle end of air intake pipe 12 is fixedly connected with support ring 37, and support ring 37 is connected with straight barrel 11, and the bottom of straight barrel 11 is fixedly connected with filter plate 10 for filtering air dust, the bottom of air intake pipe 12 Be fixedly connected with support plate 34 by fixing bolt, support plate 34 top middle end places are fixedly installed with drive mot...

Embodiment 2

[0039] Embodiment 2 is a further improvement to Embodiment 1.

[0040] Such as Figure 1-8 A high-precision electromechanical integration control device shown includes a box body 1, a first controller 5, a warning light 8, a speaker 9, a control device 17, a second controller 24, an air switch 25, an automatic release button 26, A temperature sensor 28, a smoke sensor 29, a drive motor 35 and a water pump 36, the front side wall of the box body 1 is connected with a door panel 3, the left and right side walls of the box body 1 are respectively fixedly connected with a lock 6 and a hinge 7, the lock 6 and the The hinges 7 are all connected with the door panel 3, and the door panel 3 is provided with a glass window 4 for conveniently observing the internal situation of the box body 1. The first controller 5 is fixedly installed on the box body 1, and the top of the box body 1 is fixedly connected with an alarm lamp 8 and a loudspeaker. 9 and the air intake pipe 12, the middle e...

Embodiment 3

[0042] Embodiment 3 is a further improvement to Embodiment 1.

[0043] Such as Figure 1-8 A high-precision electromechanical integration control device shown includes a box body 1, a first controller 5, a warning light 8, a speaker 9, a control device 17, a second controller 24, an air switch 25, an automatic release button 26, A temperature sensor 28, a smoke sensor 29, a drive motor 35 and a water pump 36, a door panel 3 is connected to the front side wall of the box body 1, a first controller 5 is fixedly installed on the door panel 3, and an alarm light 8 is fixedly connected to the top of the box body 1 , loudspeaker 9 and air intake pipe 12, and the middle end of the air intake pipe 12 is fixedly connected with a support ring 37, and the support ring 37 is connected with a straight cylinder 11, and the bottom of the straight cylinder 11 is fixedly connected with a filter plate 10 for filtering air dust, and the air intake pipe 12 The bottom is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com