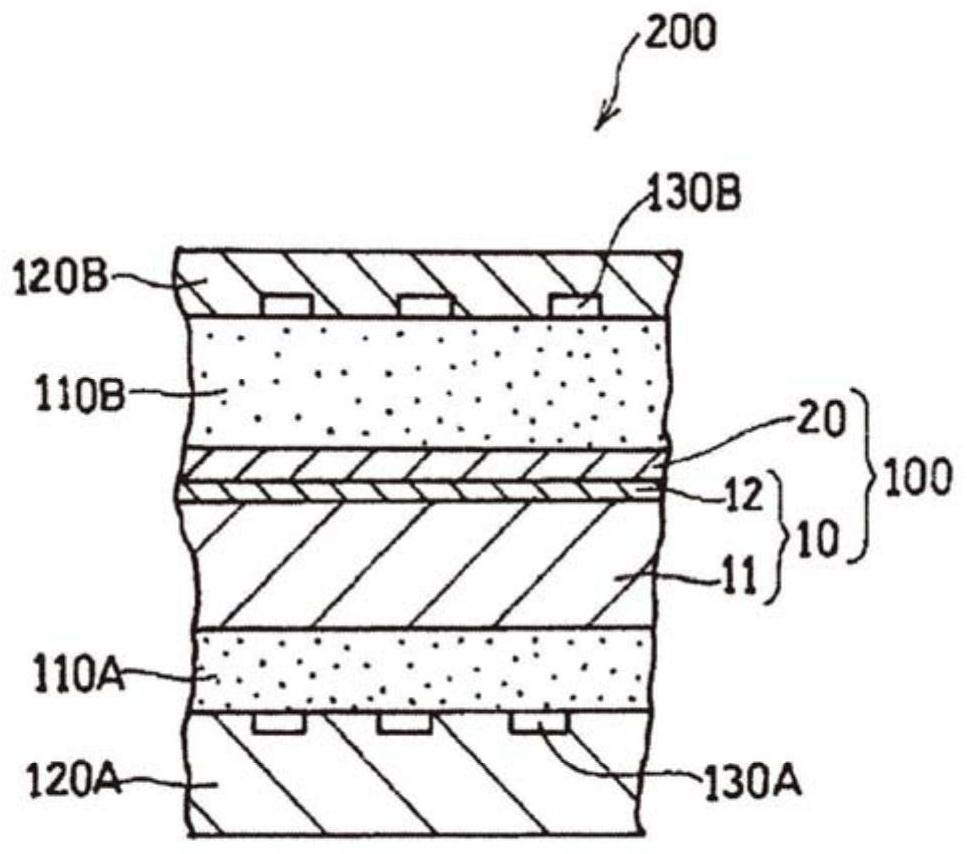

Electrolyte layer-anode composite member for fuel cell, cell structure, fuel cell, and method for manufacturing composite member

An electrolyte layer and fuel cell technology, applied in fuel cells, battery electrodes, solid electrolyte fuel cells, etc., can solve problems such as power generation performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0157] Anode A was produced by the following steps.

[0158] As an anode material, a mixed powder containing a spinel-type composite oxide (NiFe) containing Ni and Fe synthesized by an impregnation method was prepared 2 O 3 , the average particle size P 0 : 10 μm, 80% by volume) and a binder (acrylic resin, 20% by volume). Using this mixed powder, uniaxial press molding was performed to obtain a circular sheet-like molded body (precursor of an anode) having a diameter of 140 mm and a thickness of 0.8 mm.

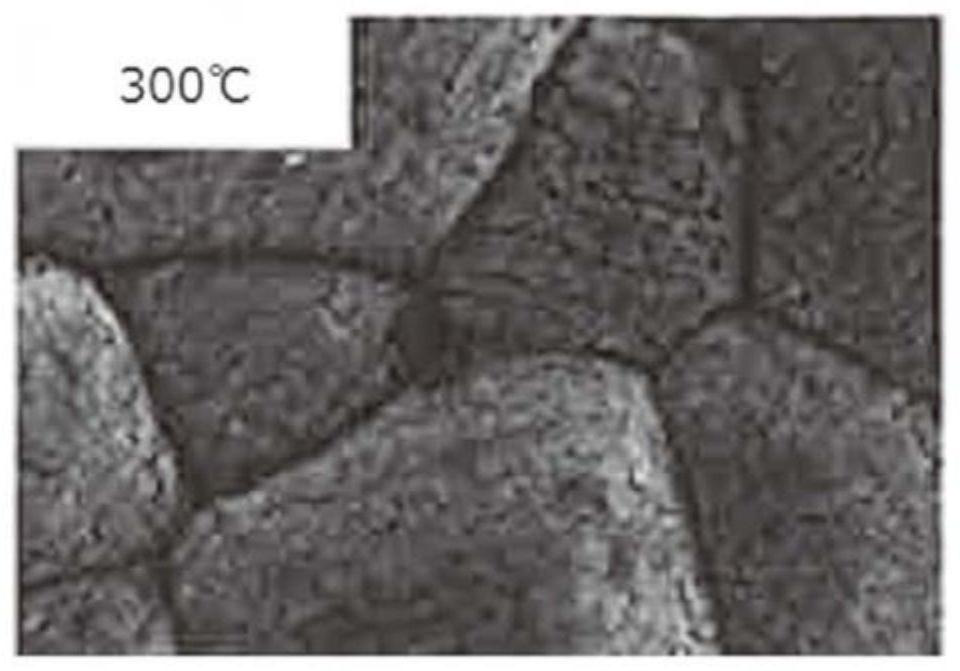

[0159] Then, in air, the obtained precursor of the anode was heated at 600°C for 1 hour to remove the binder, and thereafter fired at 1350°C for 2 hours in an oxygen atmosphere. Subsequently, the precursor of the anode was heated at 300° C. for 5 hours in a hydrogen atmosphere to reduce the composite oxide to a Ni—Fe composite metal, whereby Anode A was obtained. figure 2 A photograph of the surface of anode A taken using a scanning electron microscope (SEM) is shown. ...

manufacture example 2

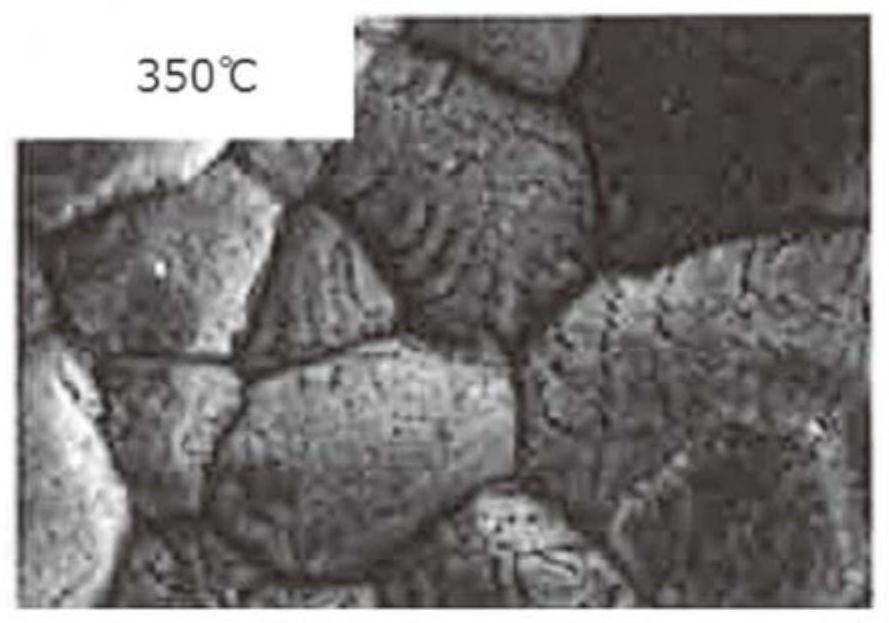

[0165]Anode B was produced and evaluated in the same manner as in Production Example 1, except that reduction treatment was performed at 350°C. Figure 8 The results are shown. in addition, image 3 A photograph of the surface of anode B taken using SEM is shown. The ratio of the bulk density Db of the anode B to the true density Dr of the Ni—Fe composite metal was 56%, and the particle diameter Pa of the particulate matter was 10 μm. In addition, the pore size P formed in the granular p is 130nm.

manufacture example 3

[0167] An anode C was produced and evaluated in the same manner as in Production Example 1, except that the reduction treatment was performed at 400°C. Figure 8 The results are shown. in addition, Figure 4 A photograph of the surface of anode C taken using SEM is shown. The ratio of the bulk density Db of the anode C to the true density Dr of the Ni—Fe composite metal was 54%, and the particle diameter Pa of the particulate matter was 24 μm. In addition, the pore size P formed in the granular p is 105nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com