Method for reducing soil moisture evaporation by using elm powder

A technology for soil moisture and elm wood powder, which is applied in land preparation methods, horticultural methods, soil conditioning materials, etc., can solve the problems of unknown type, application method and dosage of water-retaining agent, high energy consumption of mechanical farming, and high dosage of additives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

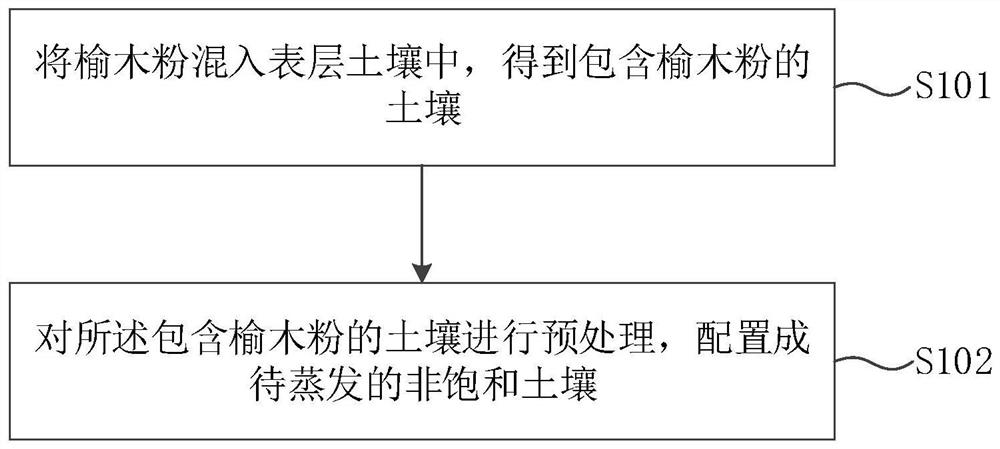

Method used

Image

Examples

Embodiment 1

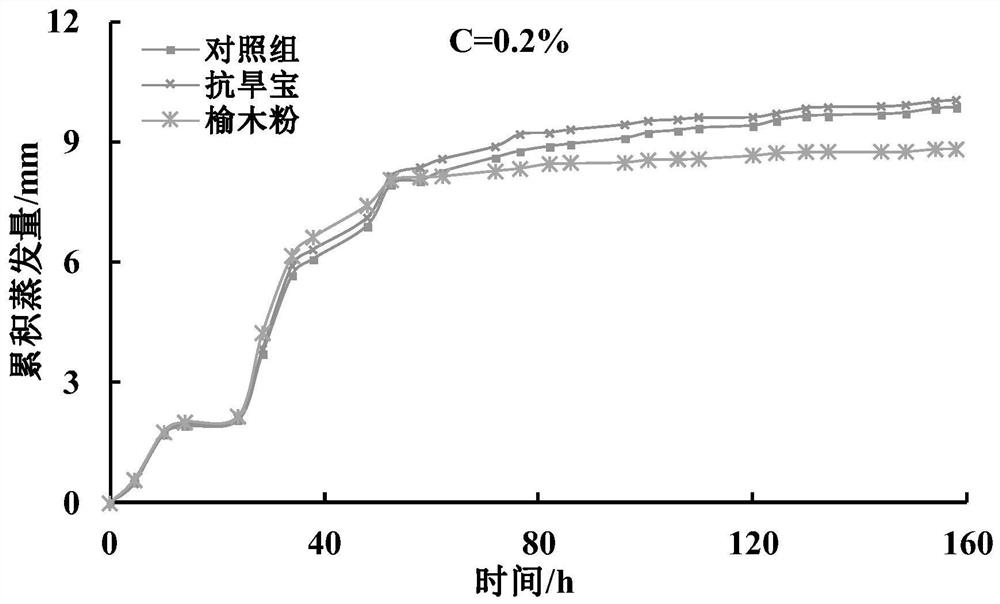

[0075] Embodiment 1 (high concentration additive evaporation test)

[0076] 1) Test materials and instruments

[0077] In the example of the present invention, the test soil is the typical red loam in Nanchang City, Jiangxi Province. The test materials and test instrument specifications / models are shown in Table 1, and the physical and chemical properties of the test soil particles are shown in Table 2.

[0078] Table 1 Test materials and instruments

[0079]

[0080] Table 2 Physical and chemical properties of test soil particles

[0081]

[0082] 2) Test plan

[0083] The inspiration of the present invention comes from Chinese opera pasting film technology. In order to fix the hair bun on the head and face, danjiao actors often soak the inner fibers of the elm bark after removing the outer skin (that is, horny hard skin) with boiling water, and the elm fiber is soaked in boiling water. After soaking, a gel will be produced, which has the characteristics of moisture ...

Embodiment 2

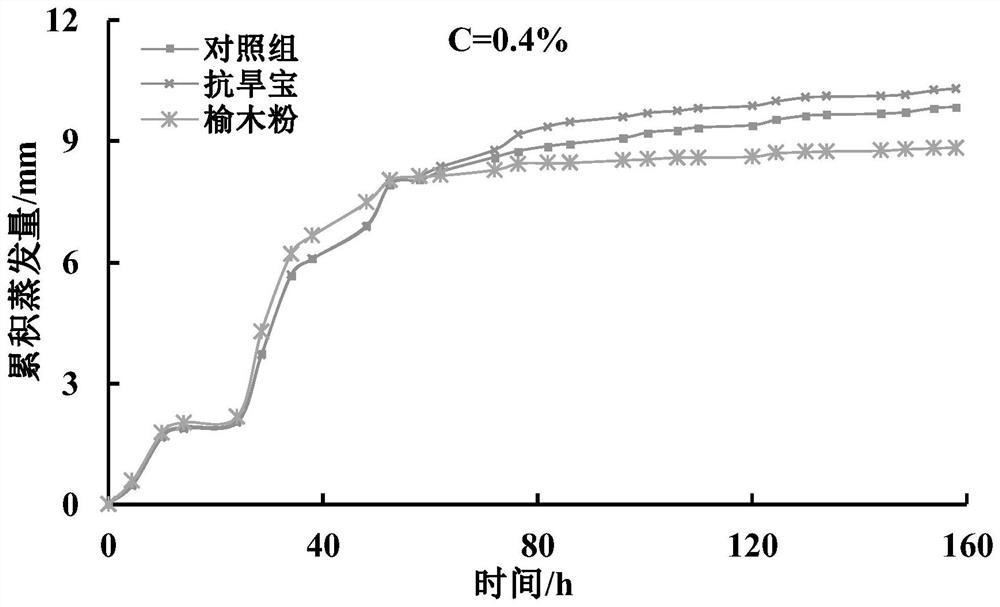

[0103] Embodiment 2 (low concentration additive evaporation test)

[0104] 1) Test materials and instruments

[0105] In this example of the present invention, the test soil is a typical red loam soil in Nanchang City, Jiangxi Province. The test materials and test instrument specifications / models are shown in the above-mentioned Table 1, and the physical and chemical properties of the test soil particles are shown in the above-mentioned Table 2.

[0106] 2) Test plan

[0107] The inspiration of the present invention comes from Chinese opera pasting film technology. In order to fix the hair bun on the head and face, danjiao actors often soak the inner fibers of the elm bark after removing the outer skin (that is, horny hard skin) with boiling water, and the elm fiber is soaked in boiling water. After soaking, a gel will be produced, which has the characteristics of moisture absorption and water retention stability. Therefore, the present invention attempts to adopt elm bark a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com