Dividing wall type continuous extraction tower

A technology of extraction tower and extraction unit, applied in the field of dividing wall continuous extraction tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

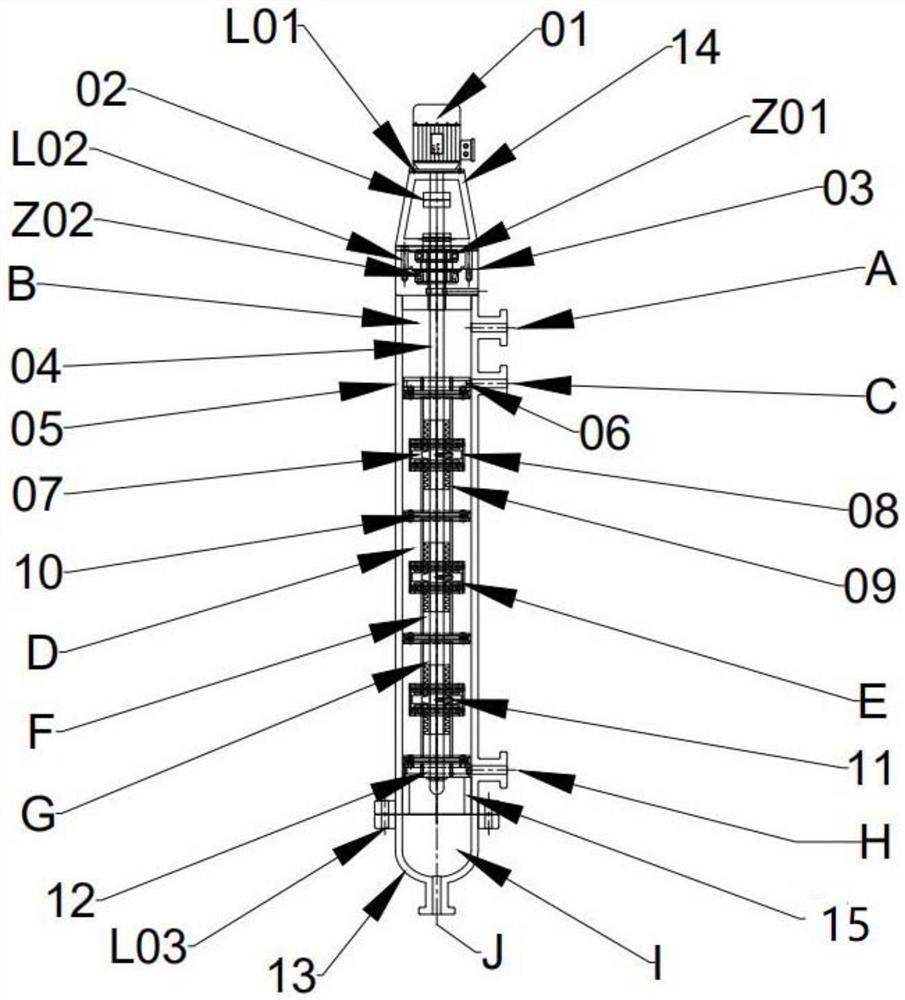

[0042] In order to make the present invention more comprehensible, an embodiment comprising 3 extraction units is described in detail below with reference to the accompanying drawings. The extraction units are upper, middle and lower extraction units from top to bottom.

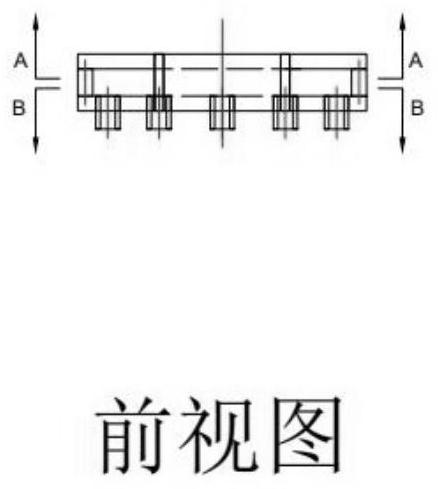

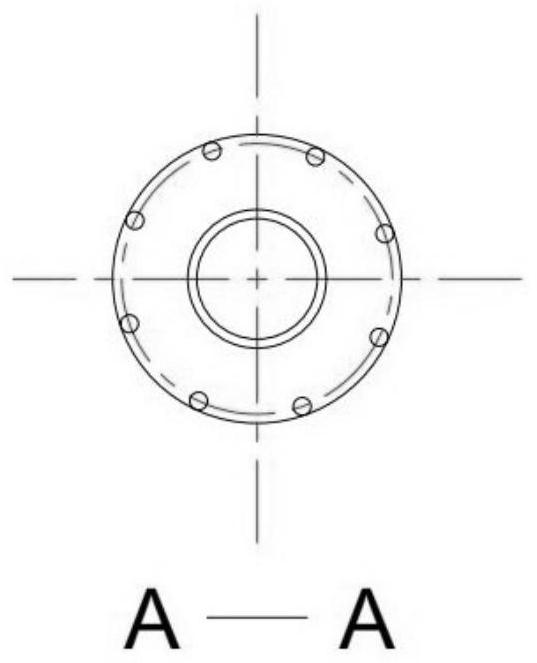

[0043] The present invention is a kind of dividing wall type continuous extraction tower, such as figure 1 As shown, it includes a motor 01, a frame 14, a shaft coupling 02, an upper end cover 03, a tower main shaft 04, a tower cylinder body 05, an upper feed distributor 06, an agitator 07, a screen cylinder 08, a partition body 09, a separator Phase plate 10, pin 11, lower feed distributor 12, lower end cover 13. The motor 01 is connected to the frame 14 through the screw 1 L01, and the frame 14 is connected to the upper end cover 03 through the screw 2 L02. The motor shaft is connected to the tower main shaft 04 in a threaded manner through the coupling 02, and the tower main shaft 04 passes through the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com