Centrifugal vortex electrostatic dust collector

An electrostatic precipitator, centrifugal technology, applied in the field of centrifugal vortex electrostatic precipitator, can solve the problem of poor dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

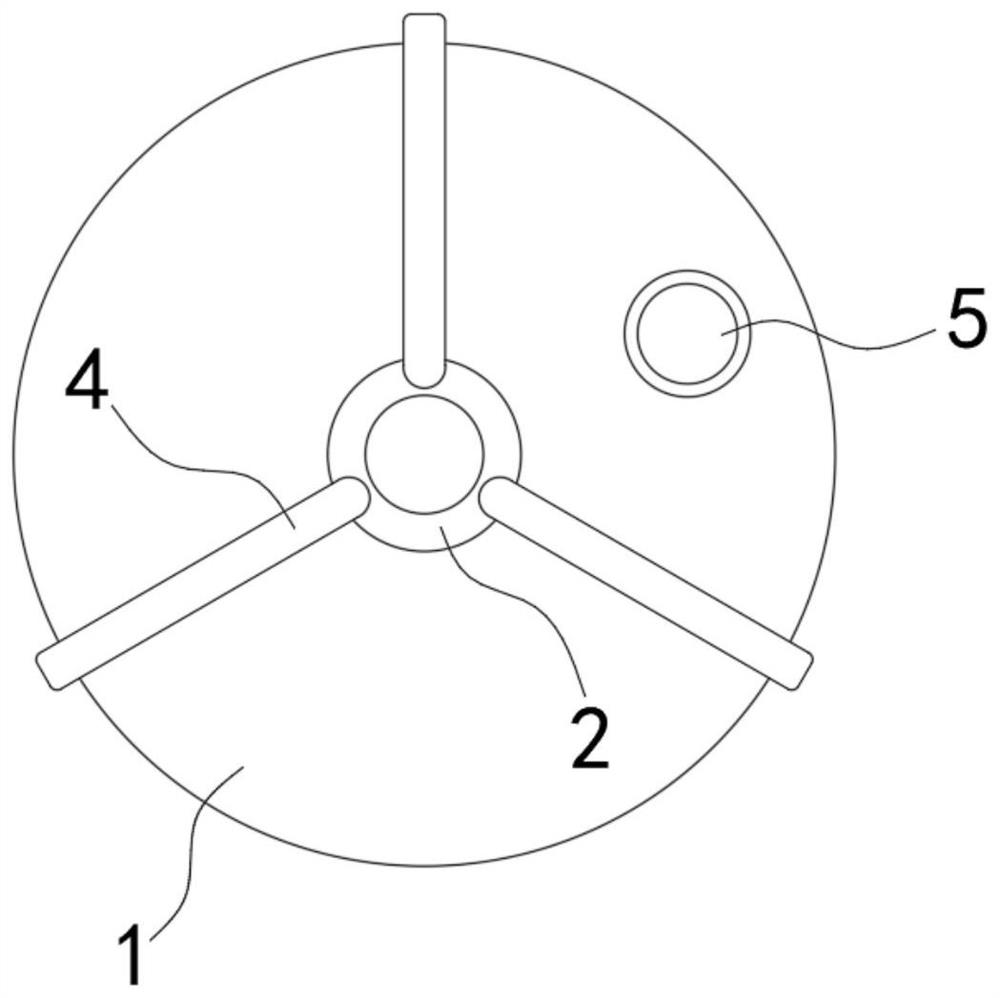

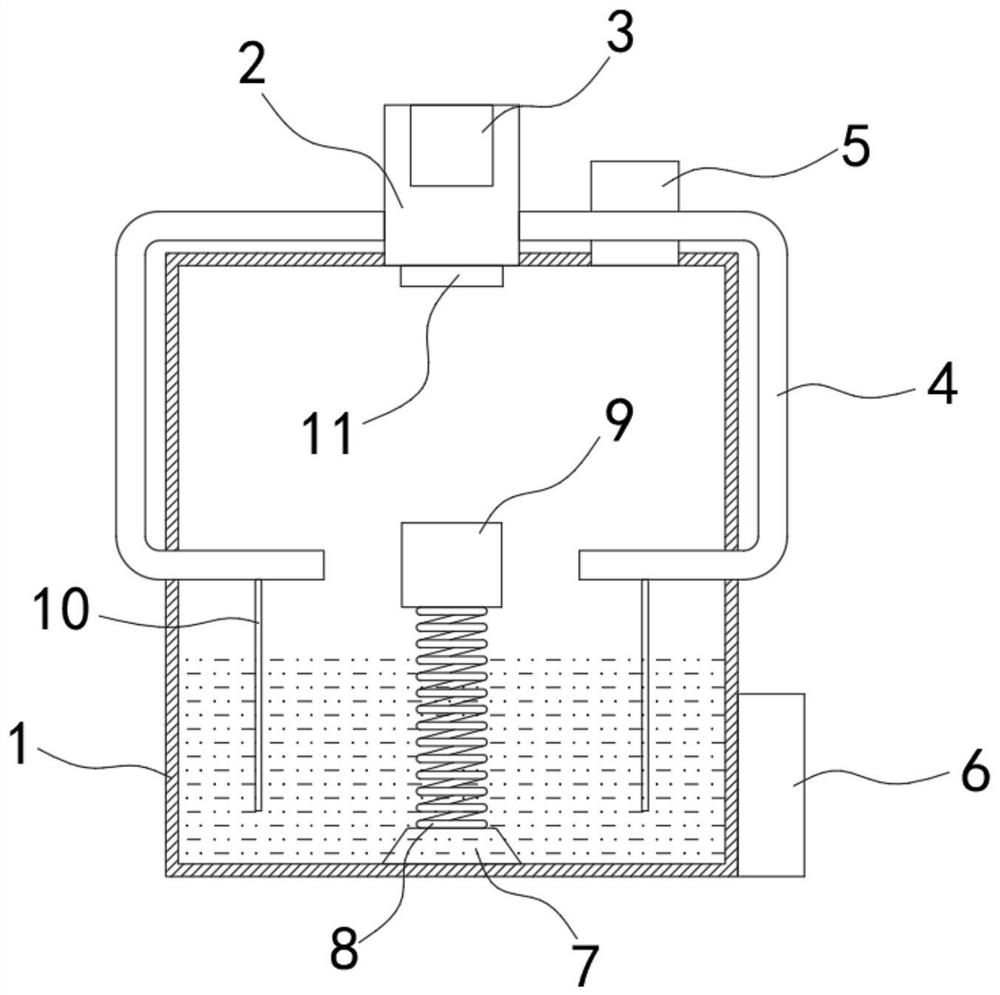

[0023] Such as Figure 1-3 As shown, a centrifugal vortex electrostatic precipitator includes a cylindrical, vertically arranged housing 1, in which water for dust removal is filled, and an air intake pipe 2 is fixedly connected to the upper end of the housing 1, and The air pipe 2 is fixedly connected with a conductive sheet 3, and the side wall of the air intake pipe 2 is fixedly connected with a plurality of shunt pipes 4. The size of each shunt pipe 4 is the same, and is evenly distributed around the air intake pipe 2, so that each shunt pipe 4 The air flow is balanced, the lower end of the shunt pipe 4 extends to the inside of the housing 1, the upper end of the housing 1 is provided with an exhaust pipe 5, the side wall of the housing 1 is fixedly connected with an electrostatic generator 6, and the bottom of the housing 1 The center position is fixedly connected with a mounting seat 7, and the upper end of the mounting seat 7 is fixedly connected with an eccentric sprin...

Embodiment 2

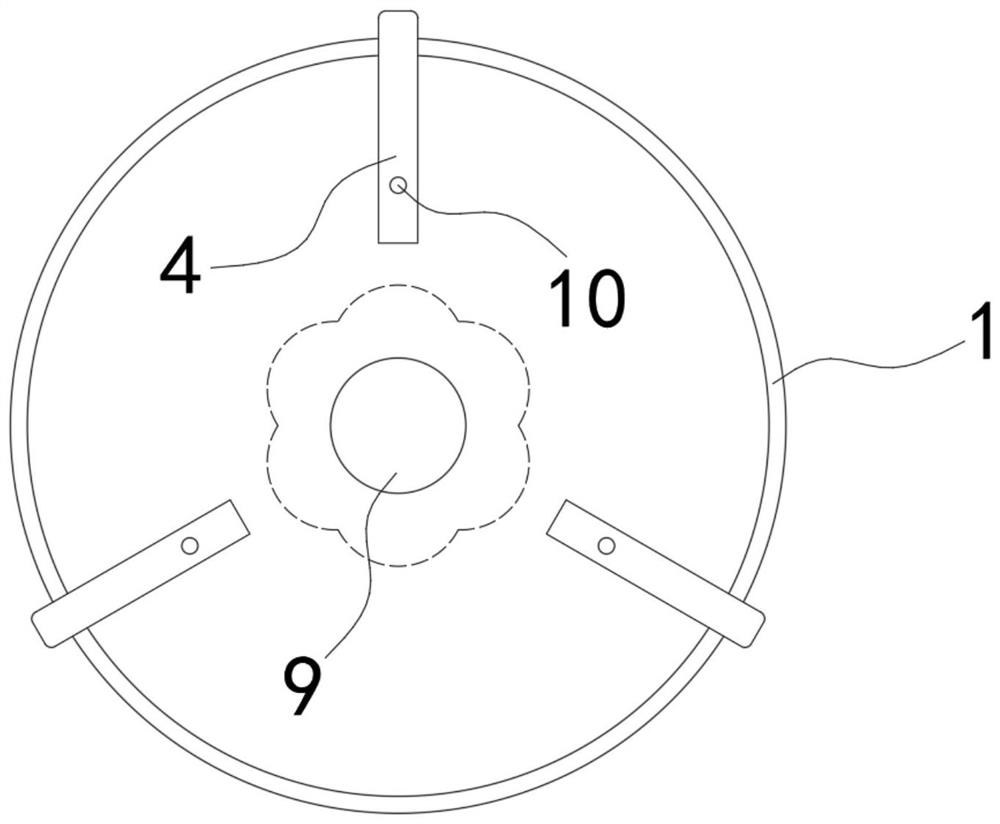

[0028] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that the output ends of each shunt tube 4 are arranged sequentially along the tangential direction of the sputtering block 9, and the output ends of each shunt tube 4 are of different lengths, as shown in Figure 5 As shown, the output end of the shunt tube 4 is located below the liquid level.

[0029] In this embodiment, since each shunt pipe 4 is distributed in the same direction around the tangential direction of the sputtering block 9, and the output ends of each shunt pipe 4 are of different lengths, that is, the exhaust speed is different, so multiple pipes will be formed in the water. The water streams that rotate around the same center and have different flow velocities will form a vortex centered on the sputtering block 9 under the action of multiple streams, with the entrance at the top and the exit at the bottom, which can continuously sputter The large particle impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com