Production process method of electronic-grade hydrofluoric acid

An electronic-grade hydrofluoric acid and production process technology, applied in hydrogen fluoride, fluorine/hydrogen fluoride and other directions, can solve the problems such as the inability to meet the quality standards in the mid-to-high-end market, and achieve the effect of quality improvement and assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

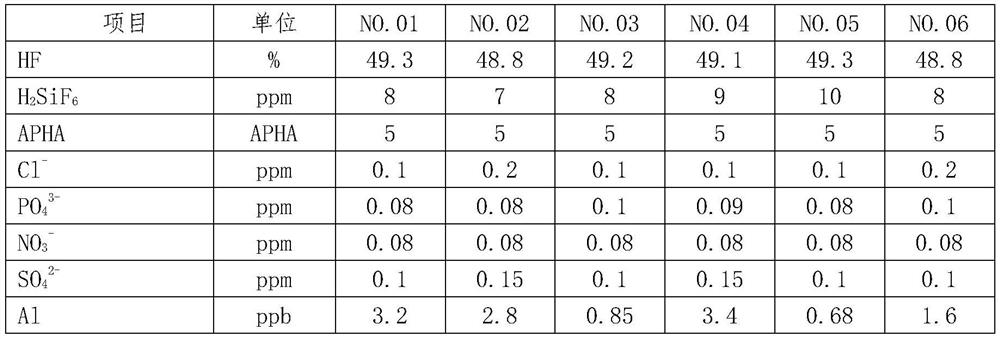

Embodiment 1

[0023] A kind of production process method of electronic grade hydrofluoric acid, its production process method comprises the following steps:

[0024] a. Pretreatment: Pump industrial anhydrous hydrogen fluoride into the degassing tower in a continuous manner to remove trace low boiling substances, and then add a strong oxidant. The strong oxidant is potassium permanganate or hydrogen peroxide or a combination of the two, and strong The amount of oxidizing agent is 0.028% of the mass of industrial anhydrous hydrogen fluoride liquid, and the strong oxidizing agent oxidizes the impurities in industrial anhydrous hydrogen fluoride, and the oxidation treatment time is 4.2h;

[0025] b. Rectification: add the pretreated industrial anhydrous hydrogen fluoride into the distillation tower for fine distillation to obtain high-purity hydrogen fluoride gas, and discharge the liquid from the bottom of the tower to prepare industrial-grade hydrofluoric acid. The temperature at the outlet ...

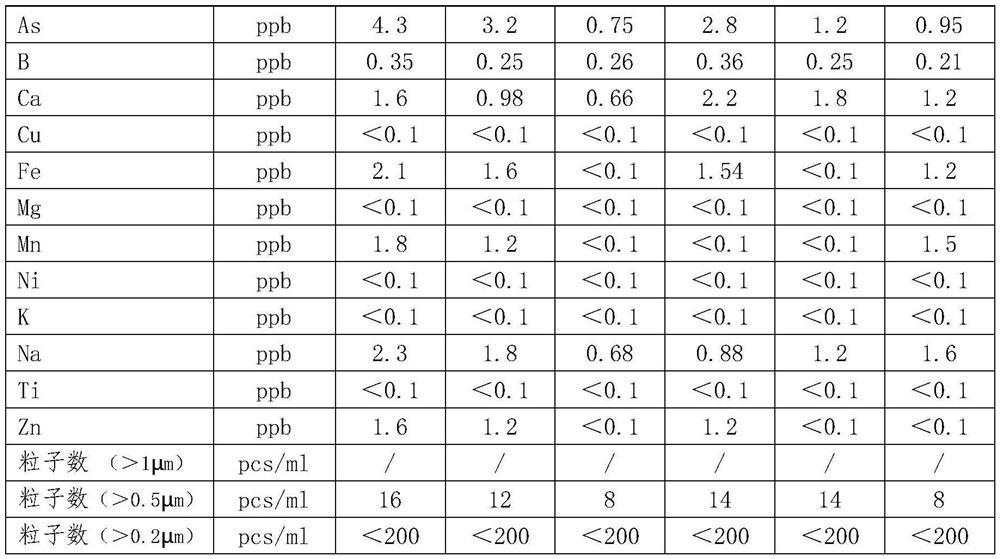

Embodiment 2

[0031] A kind of production process method of electronic grade hydrofluoric acid, its production process method comprises the following steps:

[0032] a. Pretreatment: Pump industrial anhydrous hydrogen fluoride into the degassing tower in a continuous manner to remove trace low boiling substances, and then add a strong oxidant. The strong oxidant is potassium permanganate or hydrogen peroxide or a combination of the two, and strong The amount of oxidizing agent is 0.029% of the mass of industrial anhydrous hydrogen fluoride liquid, and the strong oxidizing agent oxidizes the impurities in industrial anhydrous hydrogen fluoride, and the oxidation treatment time is 3.3h;

[0033] b. Rectification: add the pretreated industrial anhydrous hydrogen fluoride into the distillation tower for fine distillation to obtain high-purity hydrogen fluoride gas, and discharge the liquid from the bottom of the tower to prepare industrial grade hydrofluoric acid. The temperature at the outlet ...

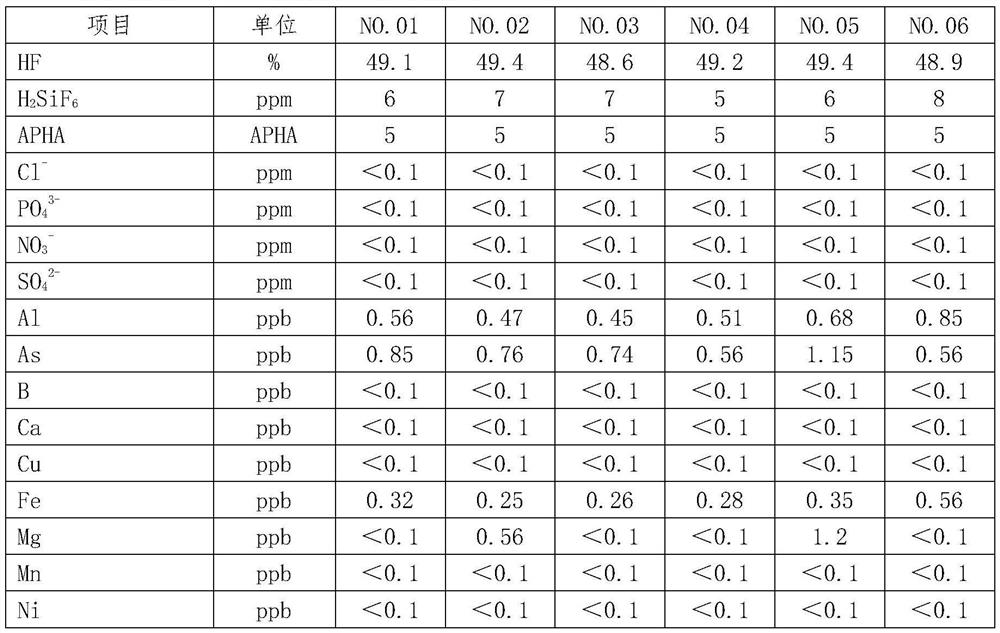

Embodiment 3

[0039] A kind of production process method of electronic grade hydrofluoric acid, its production process method comprises the following steps:

[0040] a. Pretreatment: Pump industrial anhydrous hydrogen fluoride into the degassing tower in a continuous manner to remove trace low boiling substances, and then add a strong oxidant. The strong oxidant is potassium permanganate or hydrogen peroxide or a combination of the two, and strong The amount of oxidizing agent is 0.03% of the mass of industrial anhydrous hydrogen fluoride liquid, and the strong oxidizing agent oxidizes the impurities in industrial anhydrous hydrogen fluoride, and the oxidation treatment time is 3.5h;

[0041] b. Rectification: add the pretreated industrial anhydrous hydrogen fluoride into the distillation tower for fine distillation to obtain high-purity hydrogen fluoride gas, and discharge the liquid from the bottom of the tower to prepare industrial-grade hydrofluoric acid. The temperature at the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com