Tire bead protective rubber and preparation method thereof

A kind of technology of spigot rubber and tires, which is applied in the field of rubber, can solve problems such as fatigue damage, accelerated aging of spigot rubber, and large heat generation of spigot rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

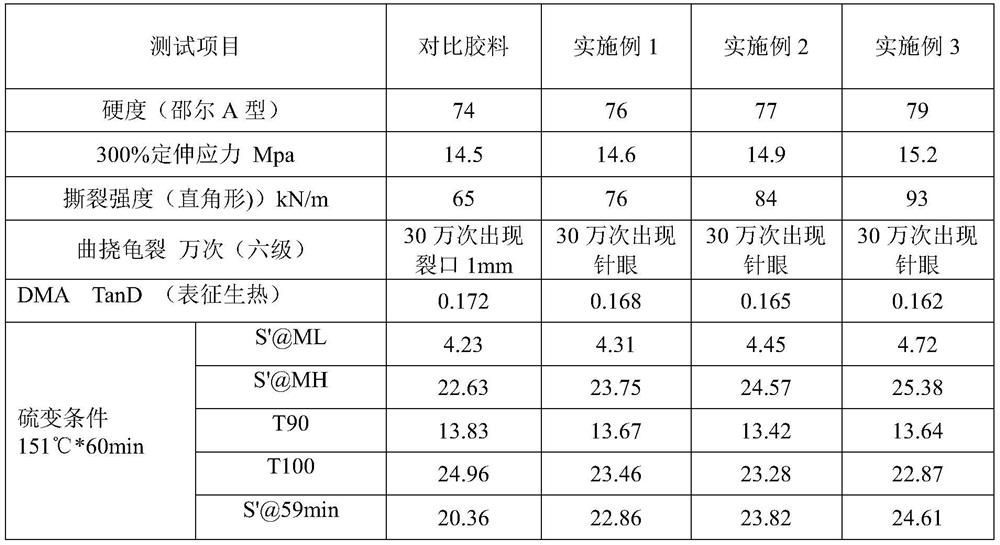

Embodiment 1

[0022] A tire rim protector, comprising the following components in parts by weight: 40 parts of natural rubber, 60 parts of high-cis-butadiene rubber, 2 parts of carbon nanotubes, 72 parts of carbon black, 4 parts of zinc oxide, hard 3 parts of fatty acid, 3 parts of anti-aging agent, 3 parts of tackifying resin, 4 parts of rubber filler oil, 1 part of rubber protective wax, 1.5 parts of accelerator, 1.4 parts of insoluble sulfur, 0.3 parts of anti-reversion agent, anti-scorch agent CTP0 .4 parts.

[0023] The carbon black is N330; the tackifying resin is Koresin super tackifying resin; the anti-reversion agent is dihydrated hexamethylene-1,6-dithiosulfate disodium salt; the anti-aging agent is anti-aging agent 4020, anti-aging agent RD and anti-aging agent 3100; the rubber filling oil is naphthenic oil; the accelerator is accelerator NS; the carbon nanotubes are multi-walled carbon nanotubes by vapor deposition method, with a diameter of 15nm, a length of 8um, and a specific...

Embodiment 2

[0029] A tire rim protector, comprising the following components in parts by weight: 40 parts of natural rubber, 60 parts of high-cis-butadiene rubber, 3 parts of carbon nanotubes, 70 parts of carbon black, 4 parts of zinc oxide, hard 3 parts of fatty acid, 3 parts of anti-aging agent, 4 parts of tackifying resin, 3 parts of rubber filler oil, 1 part of rubber protective wax, 1.5 parts of accelerator, 1.3 parts of insoluble sulfur, 0.2 parts of anti-reversion agent, anti-scorch agent CTP0 .4 parts.

[0030] The carbon black is N330; the tackifying resin is C5 tackifying resin; the anti-reversion agent is hexamethylene-1,6-dithiosulfuric acid disodium salt dihydrate; the anti-aging agent is anti-aging agent 4020 and anti-aging agent RD; The rubber filling oil is aromatic hydrocarbon oil; the accelerator is accelerator NS; the carbon nanotubes are multi-walled carbon nanotubes by gas phase precipitation, with a diameter of 12-15nm, a length of 5-12um, and a specific surface area...

Embodiment 3

[0036] A tire rim protector, comprising the following components in parts by weight: 35 parts of natural rubber, 65 parts of high-cis-butadiene rubber, 5 parts of carbon nanotubes, 66 parts of carbon black, 4 parts of zinc oxide, hard 3 parts of fatty acid, 3 parts of anti-aging agent, 3 parts of tackifying resin, 2-8 parts of rubber filler oil, 1 part of rubber protective wax, 1.4 parts of accelerator, 1.3 parts of insoluble sulfur, 0.3 parts of anti-reversion agent, anti-scorch Agent CTP 0.4 part.

[0037] The carbon black is N375; the tackifying resin is T6000 super tackifying resin; the anti-reversion agent is dihydrated hexamethylene-1,6-dithiosulfate disodium salt; the anti-aging agent is anti-aging agent 4020, anti-aging agent RD and anti-aging agent 3100; the rubber filler oil is aromatic oil; the accelerator is accelerator NS; the carbon nanotubes are multi-walled carbon nanotubes by vapor deposition method, with a diameter of 12nm, a length of 10um, and a specific su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com