High-stability, high-shading and high-adhesion environment-friendly PPA and preparation method thereof

A high stability, high shading technology, applied in the field of PPA plastics, can solve the problems of use demand, poor shading effect, poor shading performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

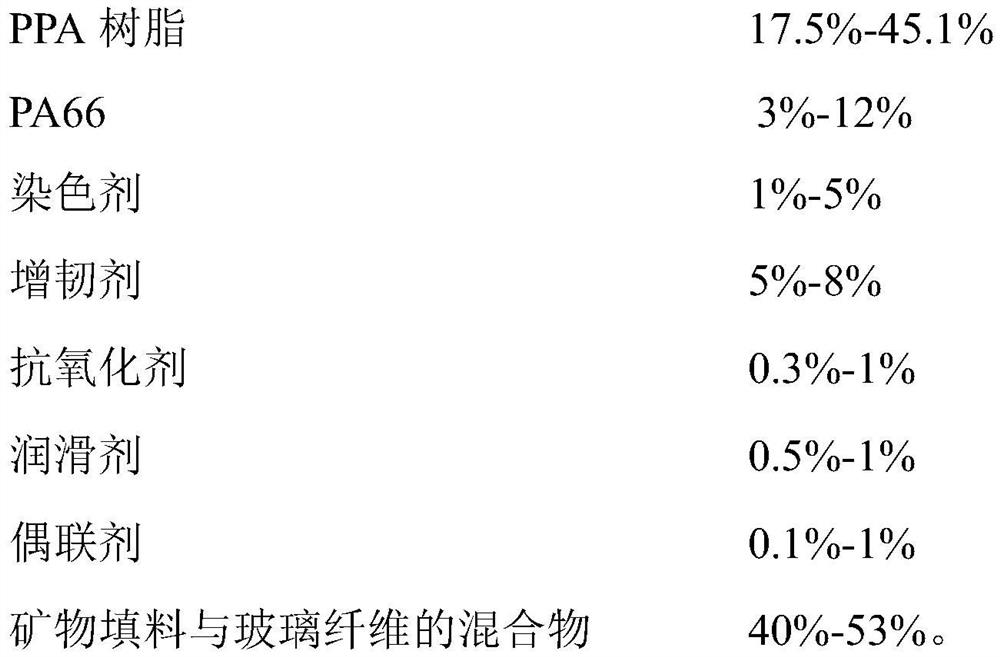

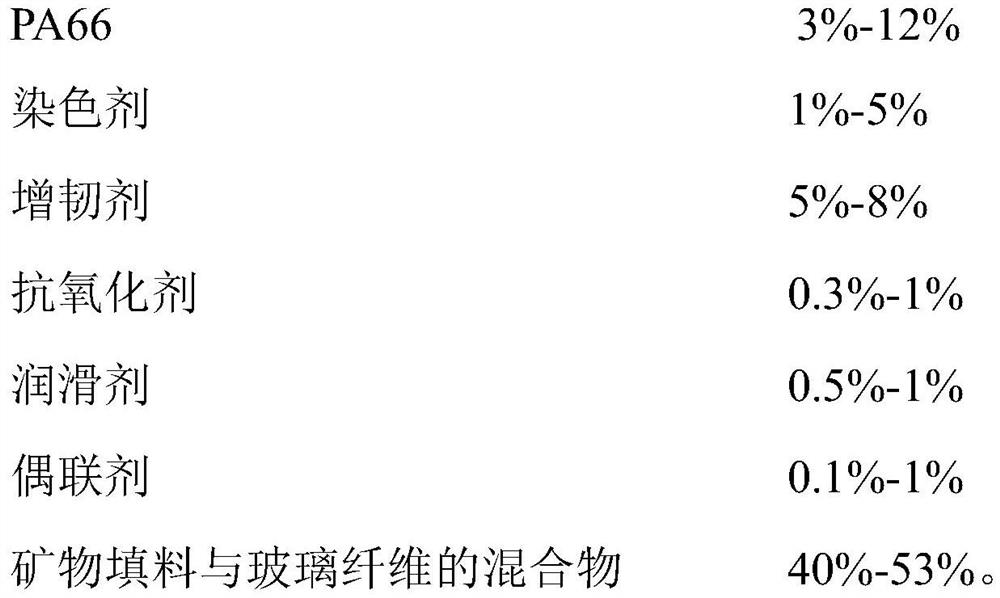

[0034] A high stability, high shading, high adhesion environment-friendly PPA, including the following raw materials by mass percentage: 17.5% PPA resin, 3% PA66, 5% toughening agent, 0.3% antioxidant, 0.5% lubricant, 0.1 A mixture of % coupling agent, 1% dyeing agent, 53% mineral filler and glass fiber.

[0035] Among them, the toughening agent is EPDM rubber, and the antioxidant is phosphite antioxidant 168. The antioxidant can also use other auxiliary materials that can play the role of anti-oxidation protection; the lubricant is stearate, and the coupling agent It is a titanate coupling agent, the dyeing agent is toner, the toner is titanium dioxide, and the mineral filler is glass microspheres; other additives include TiO2, and the proportion of TiO2 is 1%-5%.

[0036] Above-mentioned a kind of preparation method of high stability, high shading, high cleanliness environment-friendly PPA, PPA resin, PA66, toughening agent, antioxidant, lubricant, coupling agent, dyeing age...

Embodiment 2

[0038] An environment-friendly PPA with high stability, high shading and high adhesion, including the following raw materials in mass percentage: 45.1% PPA resin, 12% PA66, 8% toughening agent, 0.5% antioxidant, 1% lubricant, 1 % coupling agent, 5% dyeing agent, 40% mineral filler and glass fiber mixture.

[0039] Among them, the toughening agent is EPDM rubber, and the antioxidant is phosphite antioxidant 168. The antioxidant can also use other auxiliary materials that can play the role of anti-oxidation protection; the lubricant is stearate, and the coupling agent It is a titanate coupling agent, the dyeing agent is toner, the toner is titanium dioxide, and the mineral filler is glass microspheres; other additives include TiO2, and the proportion of TiO2 is 1%-5%.

[0040] Above-mentioned a kind of preparation method of high stability, high shading, high cleanliness environment-friendly PPA, PPA resin, PA66, toughening agent, antioxidant, lubricant, coupling agent, dyeing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com