General caliper automatic calibrating device

A verification device and caliper technology, applied in the direction of using mechanical devices, optical devices, measuring devices, etc., can solve the problems of disconnection between measurement and production, inability to provide timely and accurate feedback, and low verification efficiency, so as to improve verification efficiency and automation. , Eliminate the influence of subjective factors and reduce the effect of verification uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

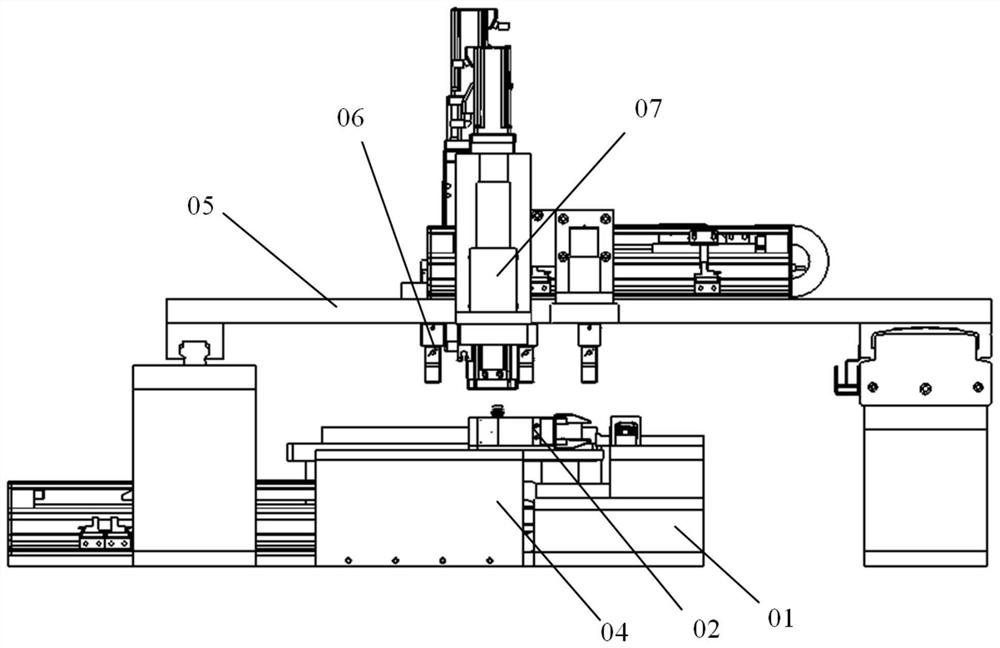

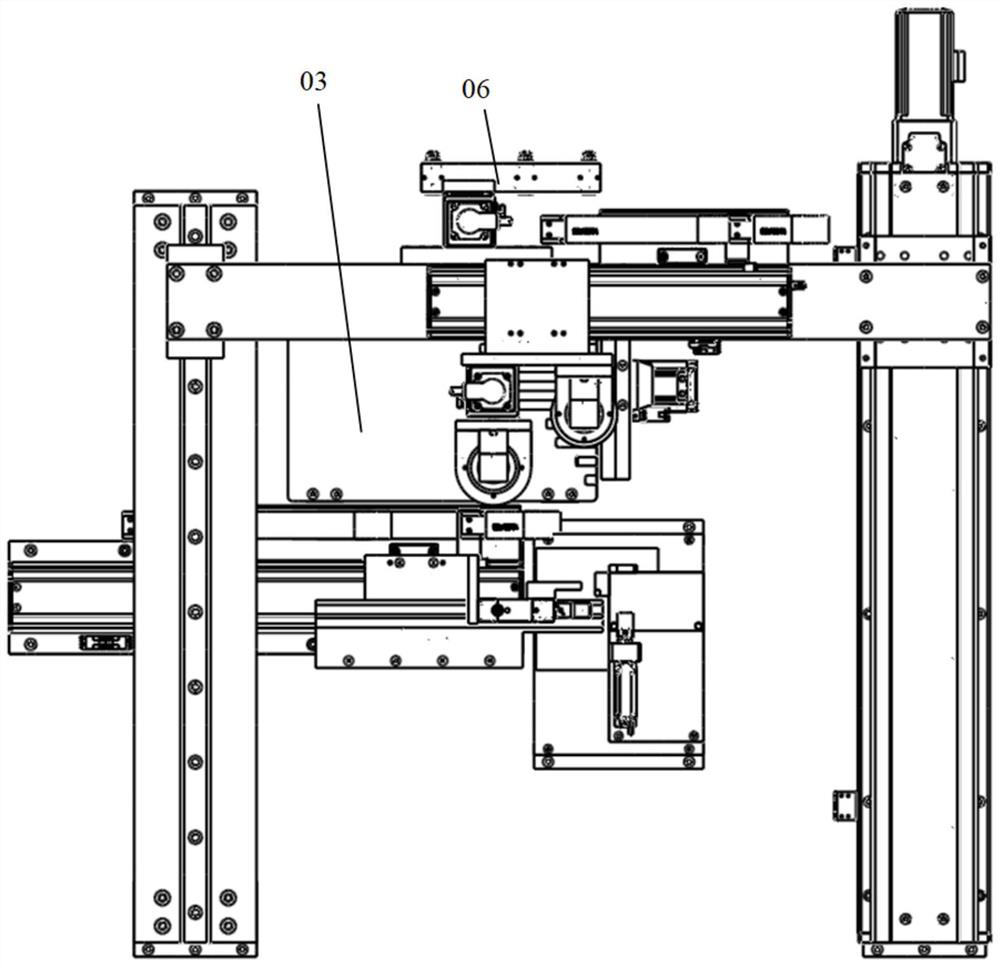

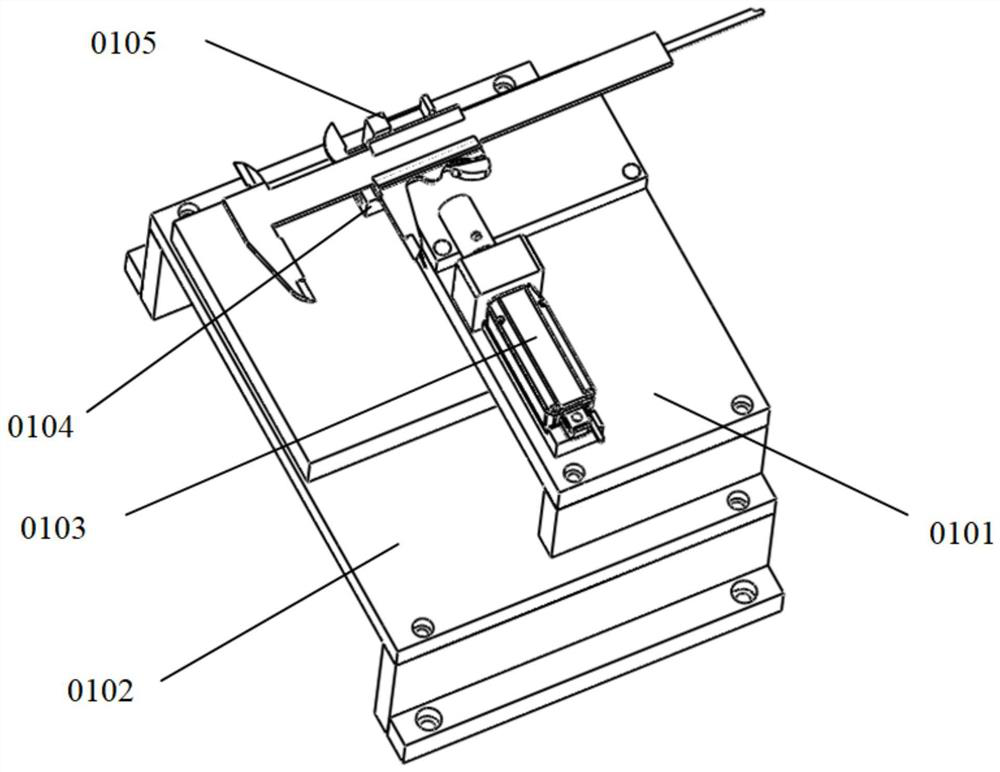

[0030] Such as figure 1 and figure 2 As shown, the caliper clamping and positioning mechanism 01 is installed at the near end of the console, the caliper clamping and dragging mechanism 02 is installed on the left side of the caliper clamping and positioning mechanism 01, the gauge block tray 03 is located at the far end of the console, and the edge of the tray is in line with the The left positioning block 0104 of the caliper clamping and positioning mechanism 01 is aligned to ensure the consistency of the lateral position when the gauge block is grasped.

[0031] The verification personnel first manually clamp the caliper to be tested on the clamping and positioning mechanism 01, and then select the caliper type in the verification software system and start the verification operation.

[0032] The first step is the verification o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com