Optical fiber sensor for perimeter security and protection

A technology of optical fiber sensor and mounting hole, which is applied in the direction of transmitting sensing components, converting sensor output, instruments, etc. by using optical devices, and can solve the problems that optical fiber sensors do not have the ability to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

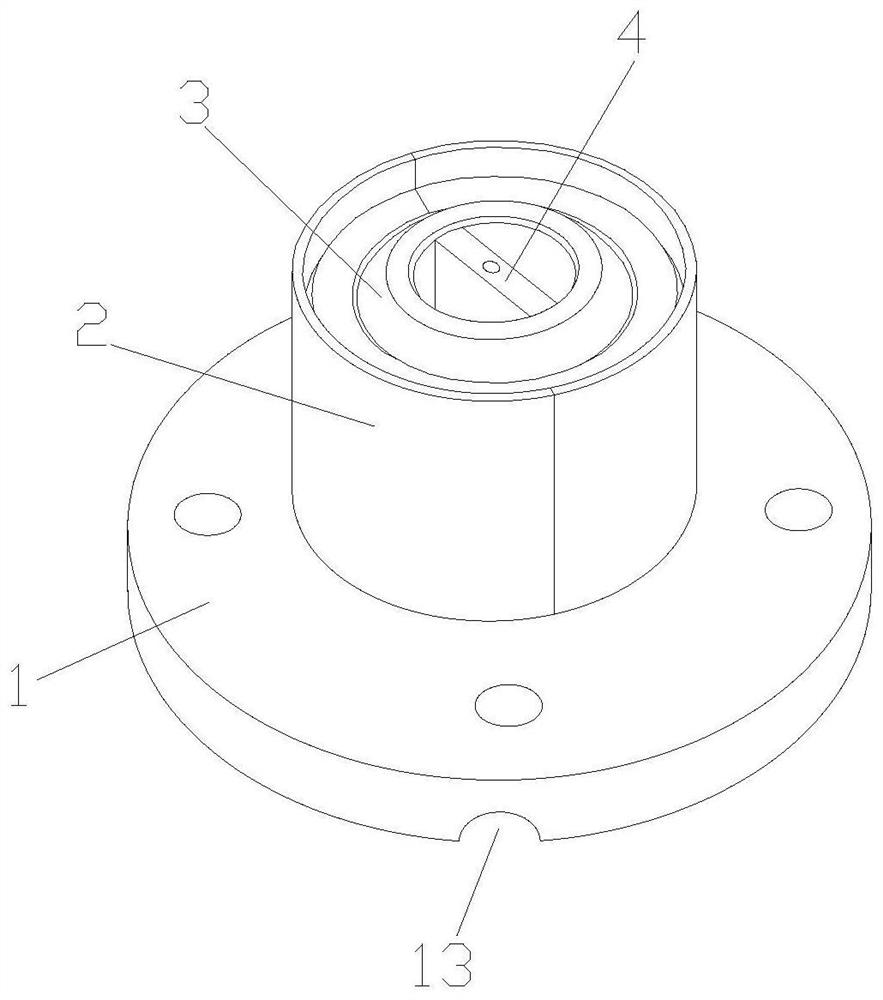

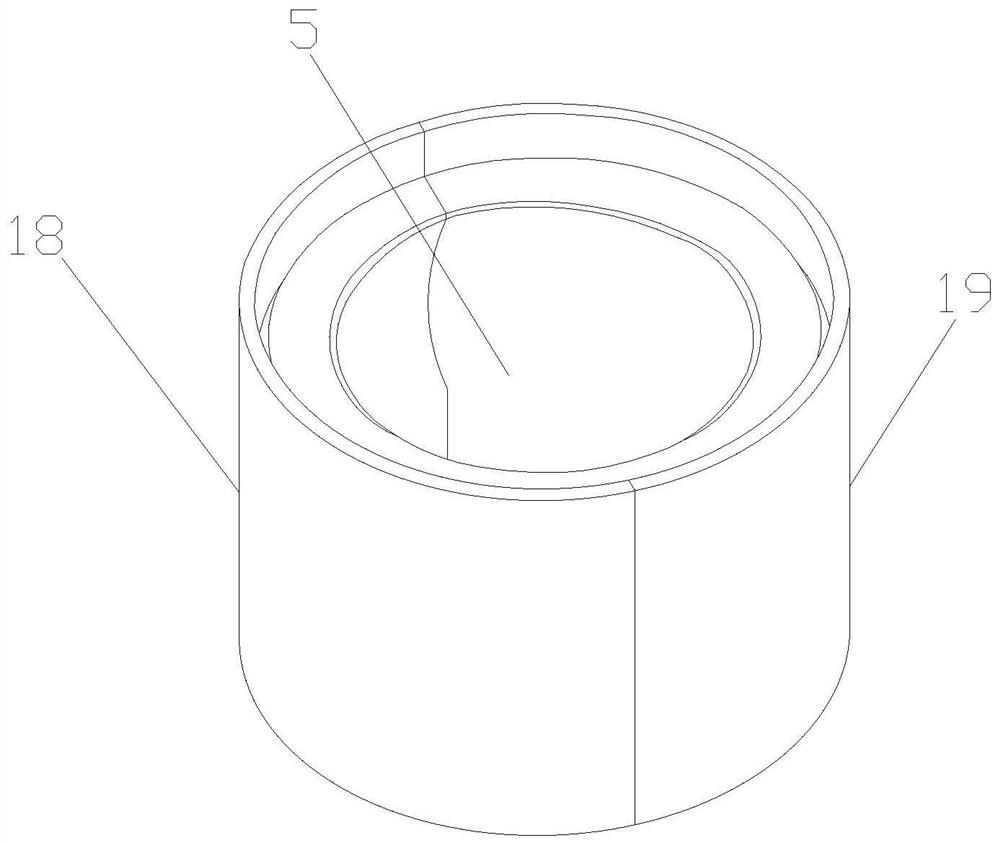

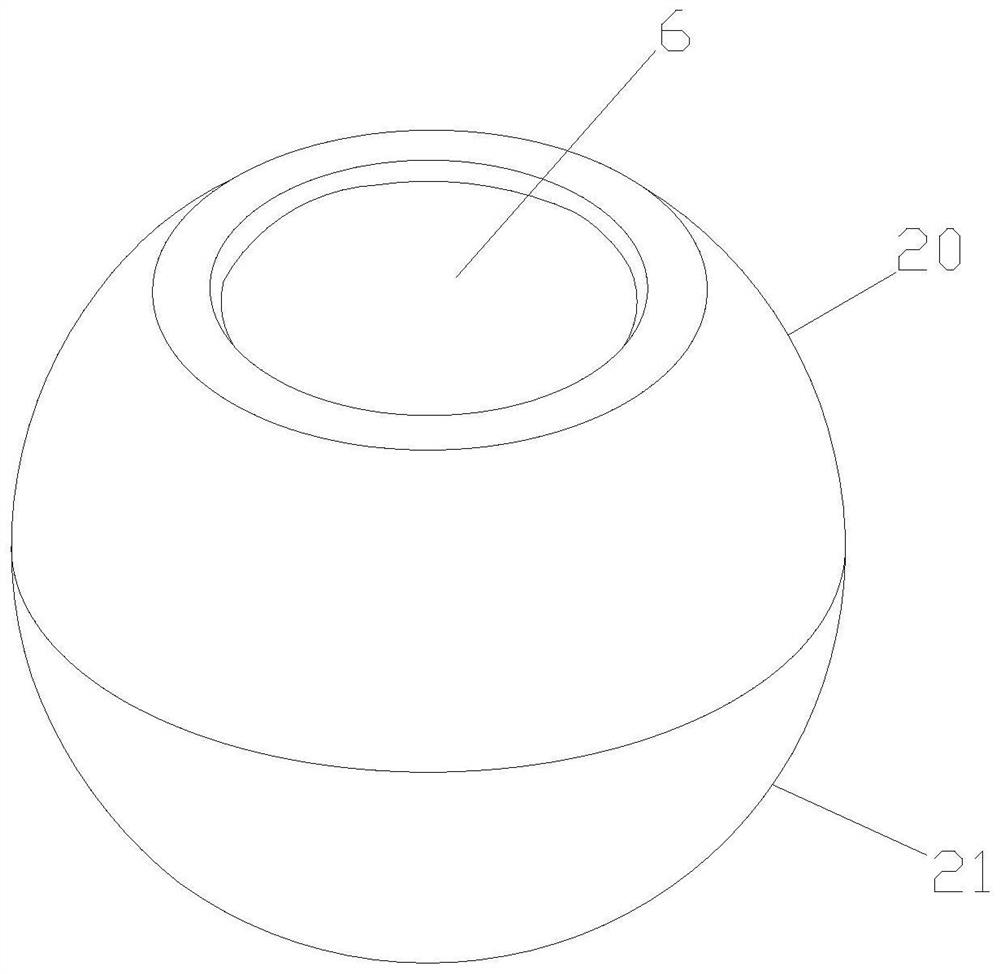

[0031] Such as Figure 1-8 As shown, a fiber optic sensor for perimeter security includes a base plate 1, an outer casing 2, a spherical inner casing 3 and a fiber optic sensor body 4, and the outer casing 2 is provided with a matching spherical inner casing 3 Joint cavity 5, the spherical inner shell 3 is installed in the joint cavity 5 and is movably connected with the outer shell 2 through the joint cavity 5, and the spherical inner shell 3 is provided with an installation hole 6 matched with the optical fiber sensor body 4 , the optical fiber sensor body 4 is installed in the installation hole 6, the outer casing 2 is provided with a connection hole (not shown), the connection hole communicates with the joint cavity 5, and the base plate 1 is provided with an electric turntable 7 and return spring 8, the middle part of the electric turntable 7 is provided with a perforation 9, the electric turntable 7 and return spring 8 are inserted into the connection hole, one end of th...

Embodiment 2

[0034] Such as Figure 1-8 As shown, a fiber optic sensor for perimeter security includes a base plate 1, an outer casing 2, a spherical inner casing 3 and a fiber optic sensor body 4, and the outer casing 2 is provided with a matching spherical inner casing 3 Joint cavity 5, the spherical inner shell 3 is installed in the joint cavity 5 and is movably connected with the outer shell 2 through the joint cavity 5, and the spherical inner shell 3 is provided with an installation hole 6 matched with the optical fiber sensor body 4 , the optical fiber sensor body 4 is installed in the installation hole 6, the outer casing 2 is provided with a connection hole (not shown), the connection hole communicates with the joint cavity 5, and the base plate 1 is provided with an electric turntable 7 and return spring 8, the middle part of the electric turntable 7 is provided with a perforation 9, the electric turntable 7 and return spring 8 are inserted into the connection hole, one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com