Optical lens with laser-induced periodic surface microstructure

A technology of optical lenses and microstructures, applied in optics, optical components, laser welding equipment, etc., can solve problems such as cumbersome processes, unstable optical functions, and uneven distribution of micro-nano structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

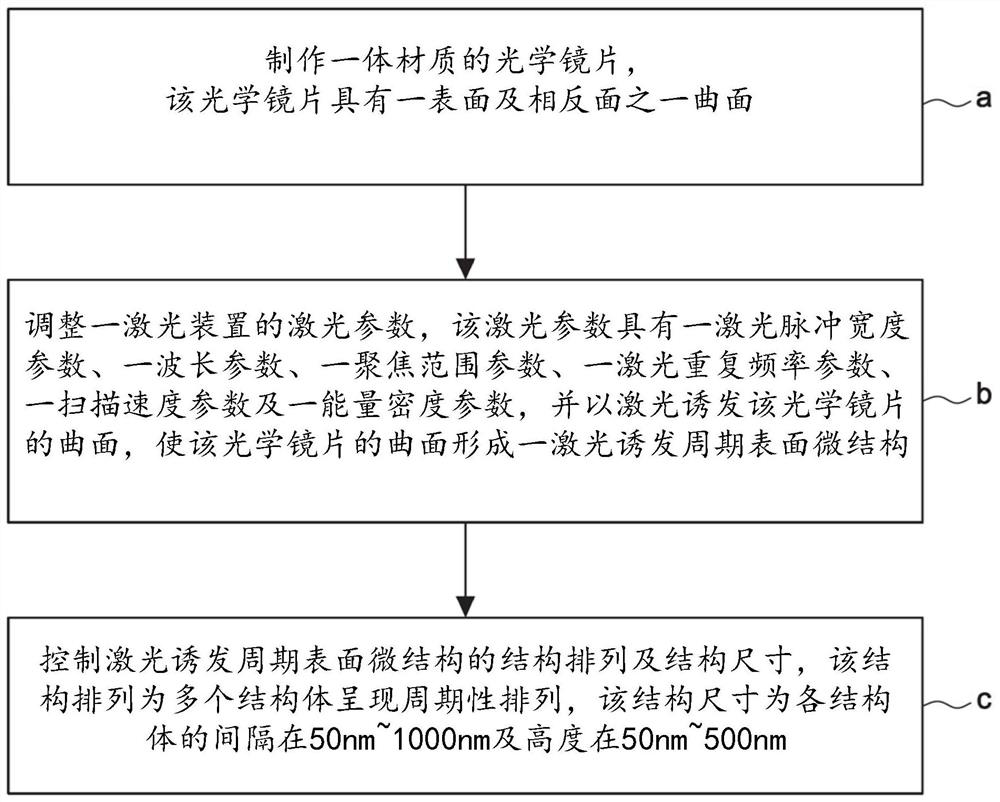

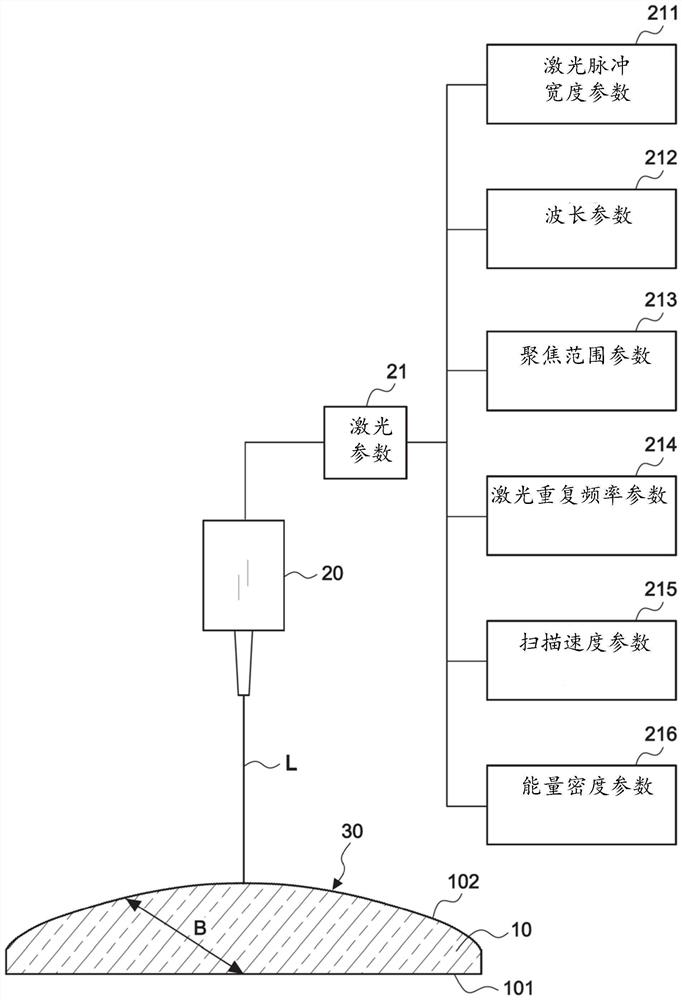

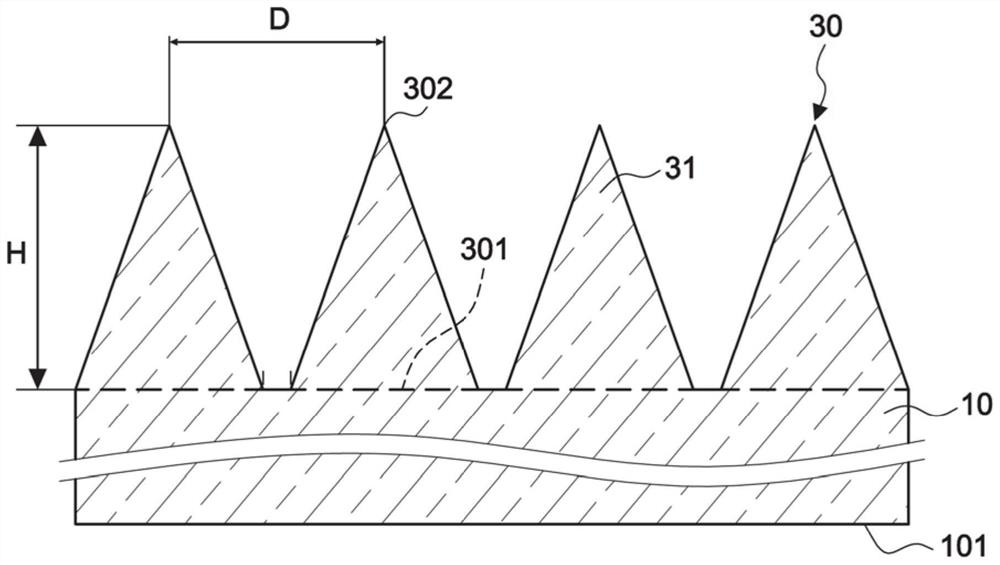

[0034] First, see figure 1 As shown in the flow chart, an optical lens with a laser-induced periodic surface microstructure of the present invention comprises the following steps: a). Making an optical lens 10 made of an integral material, the optical lens 10 has a surface 101 and an opposite surface A curved surface 102; b). Adjust the laser parameter 21 of a laser device 20, the laser parameter 21 has a laser pulse width parameter 211, a wavelength parameter 212, a focal range parameter 213, a laser repetition rate parameter 214, and a scanning speed parameter 215 and an energy density parameter 216, and induce the curved surface 102 of the optical lens 10 with a laser, so that the curved surface 102 of the optical lens forms a laser-induced periodic surface microstructure (Laser Induced Periodic Surface Structure, LIPSS) 30; and c) . Controlling the structure arrangement and structure size of the laser-induced periodic surface microstructure 30, the structure arrangement is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com