Photovoltaic module diode tin pre-storage device based on crest welder

A photovoltaic module and wave soldering machine technology, applied in the direction of tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems affecting the quality, appearance, thickness of photovoltaic module diodes, low efficiency of tin feeding, etc., and achieve uniformity Consistent, highly stable, good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

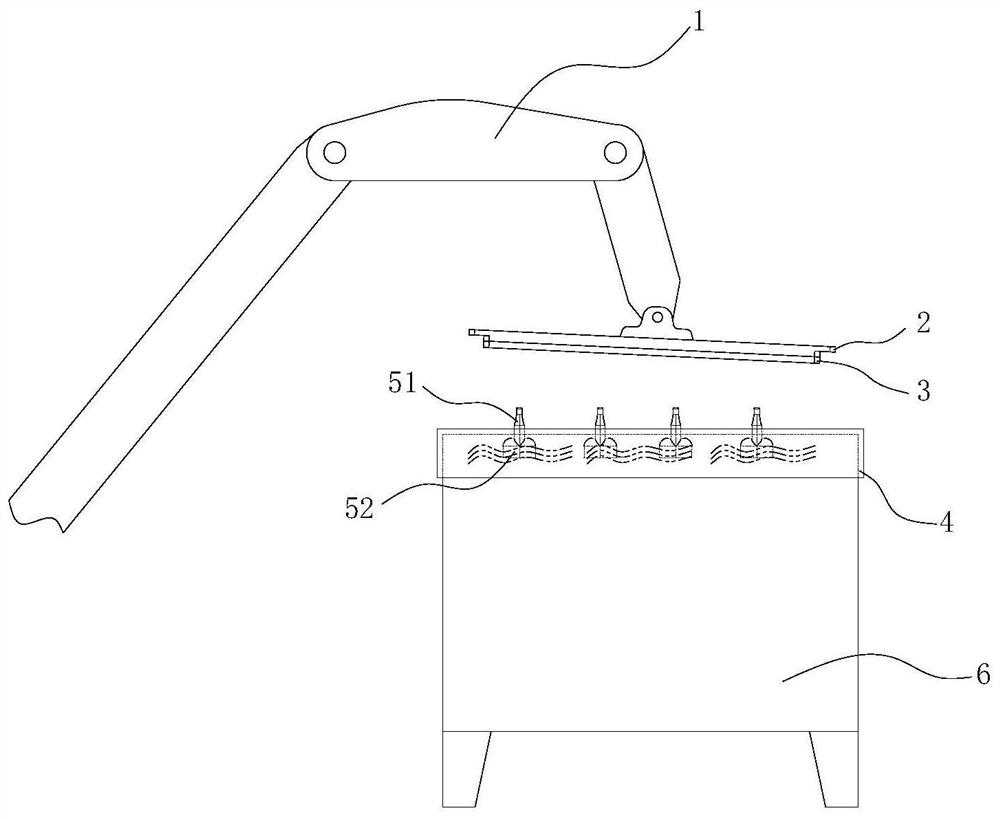

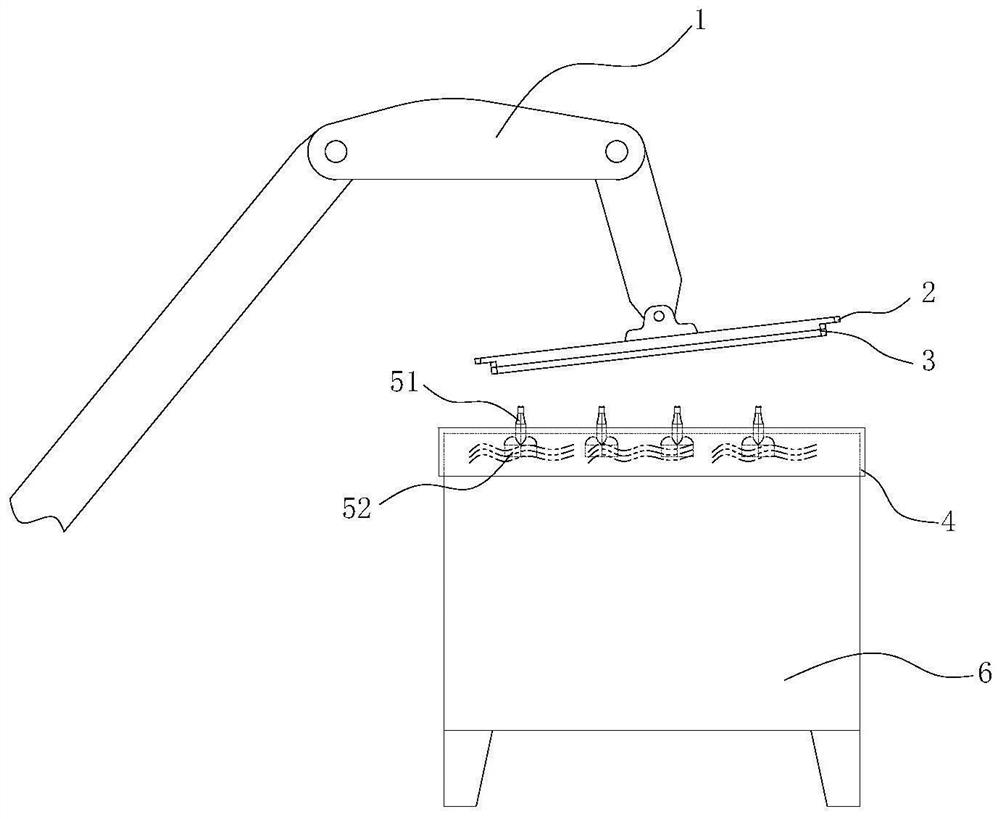

[0044] The following is attached Figure 1-18 Further illustrate the present invention, the present invention comprises mechanical arm 1 and wave soldering machine 6, and mechanical arm 1 is arranged on the top of wave soldering machine 6,

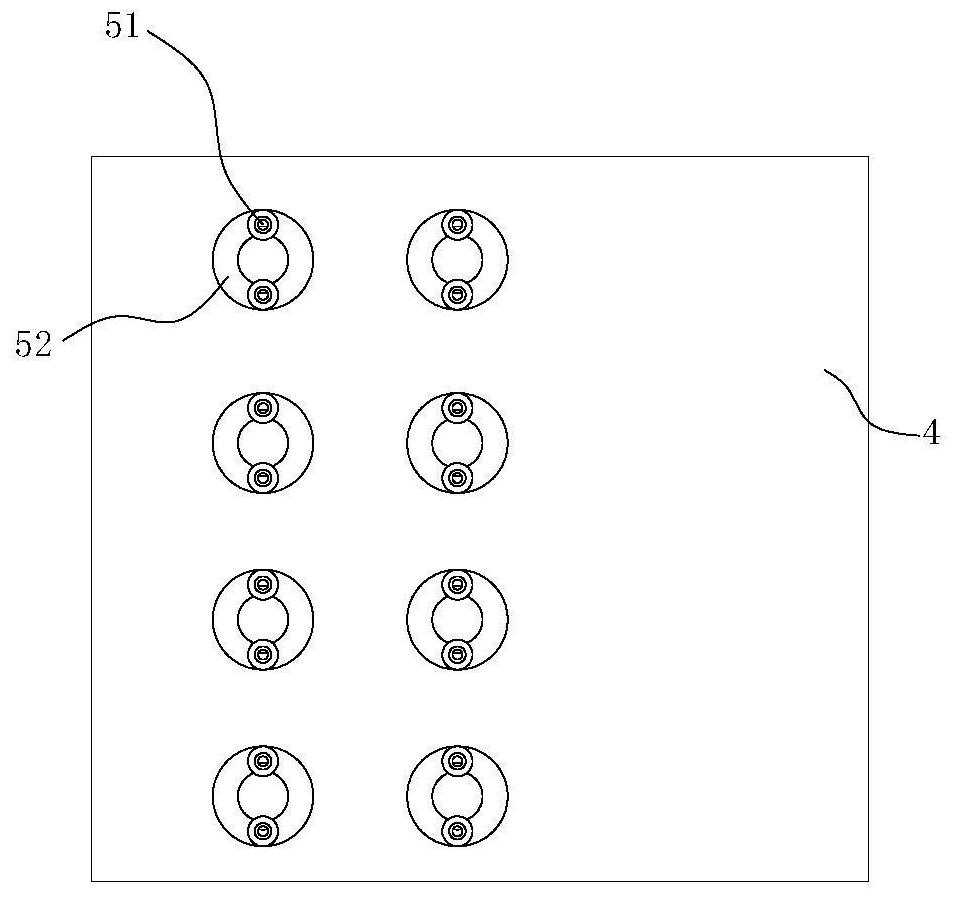

[0045] The clamping end of the mechanical arm 1 is also equipped with a photovoltaic module diode tin storage jig, and the top surface of the melting pool of the wave soldering machine 6 is also covered with a tin feeding cover 4, and the tin feeding cover 4 and the wave soldering machine 6 melt tin The top surface of the pool is sealed so that the molten tin liquid can squeeze upward into the tin guide head;

[0046] Photovoltaic module diode tin storage fixture includes a back plate 2 and a cover plate 3, the back of the back plate 2 is fixedly connected to the clamping end of the mechanical arm 1, and the front of the back plate 2 is provided with several groups of grooves 21, the grooves 21 are used to accommodate photovoltaic module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com