OLED display panel bright spot defect correction system

A technology for display panel and bright spot defects, used in microscopes, instruments, electrical components, etc., can solve problems such as strict beam focusing requirements, poor repair system adaptability, and poor repair results, and achieve improved detail resolution, simple structure, The effect of uniform brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

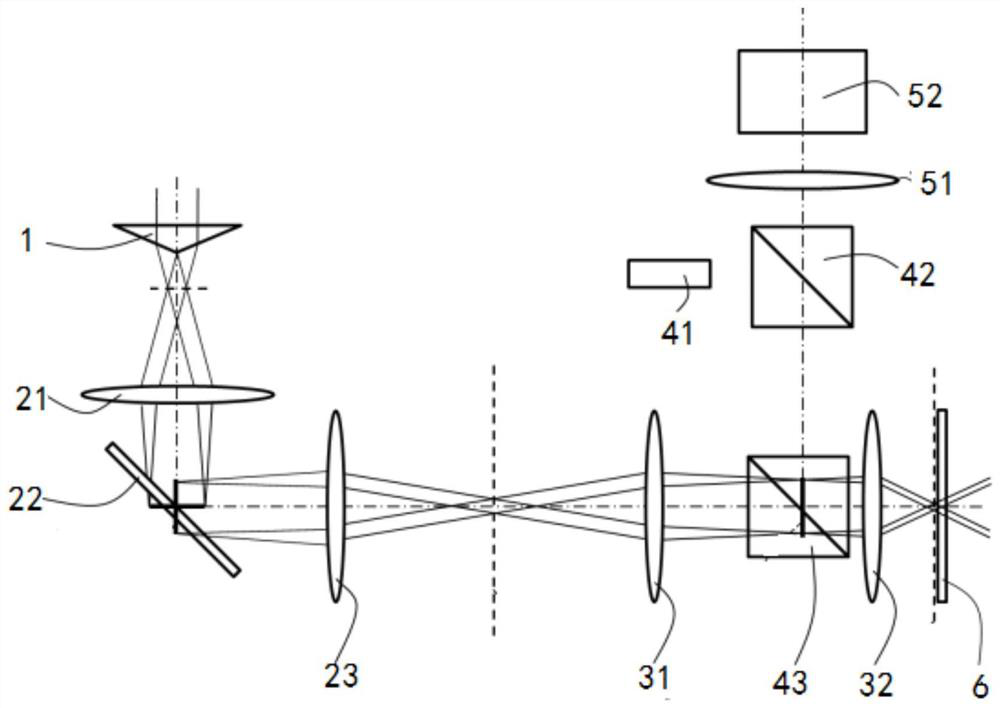

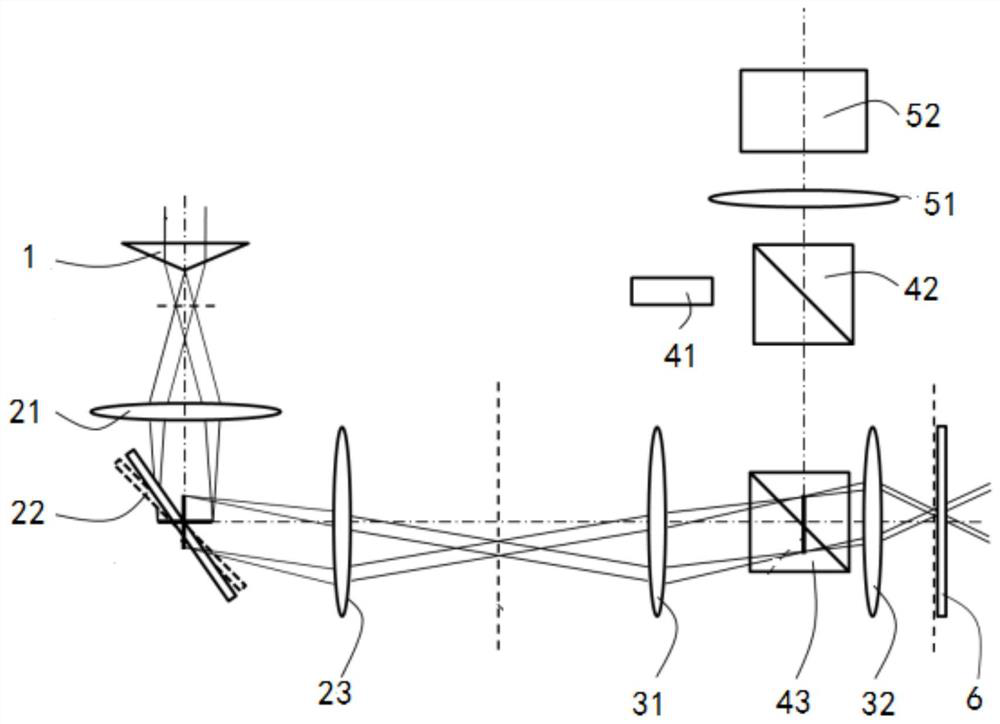

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

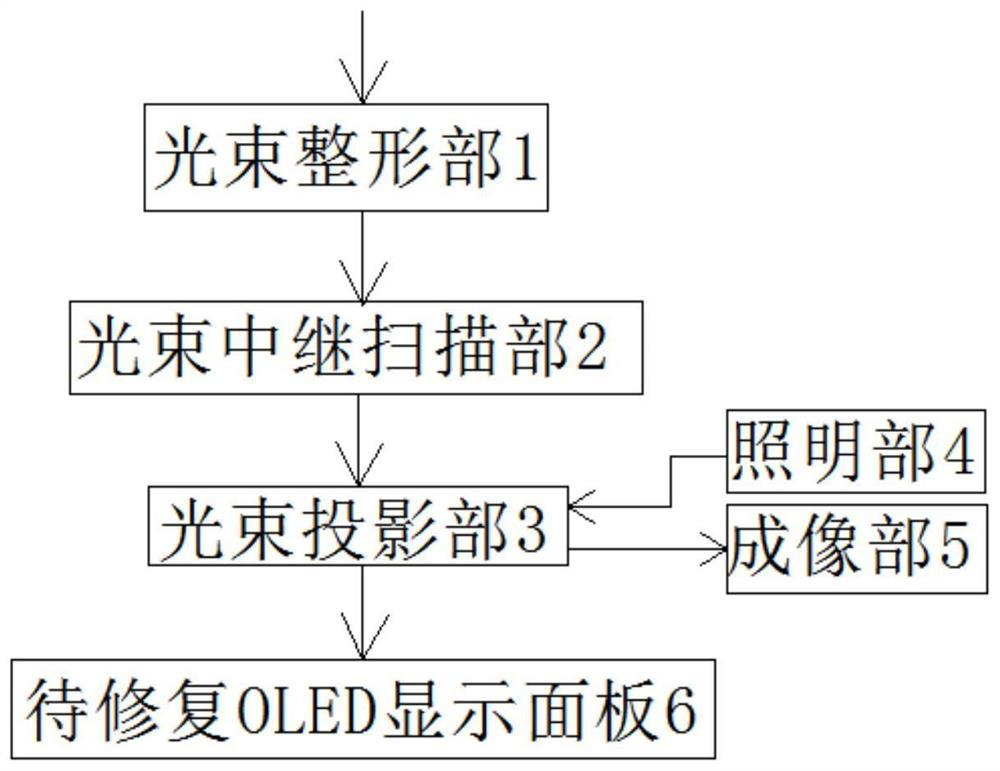

[0037] like figure 1 and Figure 5 As shown, this embodiment provides a bright spot defect correction system for an OLED display panel, including a beam shaping unit 1, a beam relay scanning unit 2, a beam projection unit 3, an illumination unit 4 and an imaging unit 5;

[0038] The beam shaping unit 1 is used to shape the incident Gaussian beam into a Gaussian-Bessel beam and output it, and the output optical path has a first Bessel region;

[0039] The beam relay scanning part 2 is arranged on the output optical path of the beam shaping part 1, which is used to relay the Gauss-Bessel beam output by the beam shaping part 1 to the far field, and make the Gaussian - Bessel beam off-axis and beam scanning;

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com