Preparation method and application of water-in-oil type liquid vitamin premix

A technology of vitamin premix and liquid vitamin, which is applied in the application, molding or processing of animal feed, animal feed, etc. It can solve the problems of feed mildew and vitamin loss, and achieve the effect of avoiding the increase of feed moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1.1 Preparation of liquid vitamin premix for pigs:

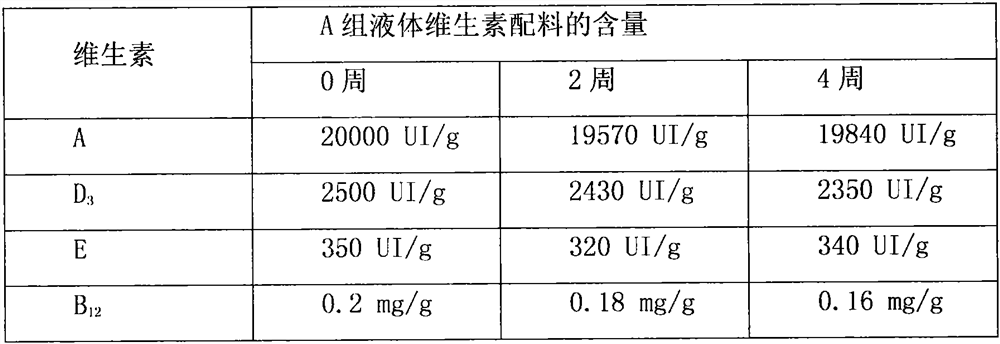

[0022] A group of liquid vitamin ingredients, its composition ratio is as follows: vitamin A acetate (oil agent) 20MIU / kg, vitamin D 3 (oil) 2.5MIU / kg, DL-α-tocopheryl acetate (oil) 0.35MIU / kg, vitamin B 12 The concentration is 0.2g / kg, ethoxyquinoline 20g / kg, soybean oil 65g / kg, ethyl lactate 265g / kg, 1,2-propanediol 50g / kg, monoglyceride 166g / kg, Span 8034g / kg . The preparation procedure is as follows: in the dosing tank, add 1,2-propanediol to B under stirring 12 In medium, continue stirring for 5 minutes to ensure even mixing. Ethyl lactate was then added to the mixture, followed by soybean oil. While continuing to stir, add ethoxyquinoline vitamins E, A, and D in turn. Finally, monoglyceride and Span 80 are added to the homogeneous liquid to make group A liquid vitamin ingredients;

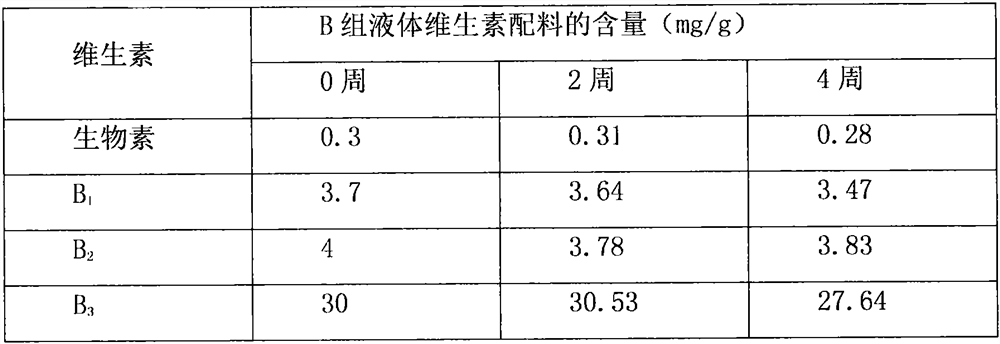

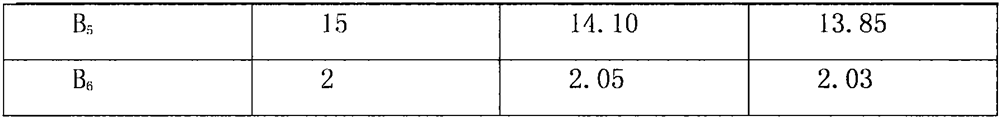

[0023] Group B liquid vitamin batching, its composition ratio is as follows: biotin 0.3g / kg, pyridoxine hydrochloride (B 6 )...

Embodiment 2

[0032] 2.1 Preparation of liquid vitamin premix for chicken:

[0033] A group of liquid vitamin ingredients, its composition ratio is as follows: vitamin A acetate (oil agent) 40MIU / kg, vitamin D 3 (oil) 10MIU / kg, DL-α-tocopheryl acetate (oil) 0.2MIU / kg, vitamin B 12 The concentration is 0.1g / kg, ethoxyquinoline 25g / kg, soybean oil 124g / kg, ethyl lactate 300g / kg, 1,2-propanediol 55g / kg, monoglyceride 166g / kg, Span 80 34g. The preparation procedure is as follows: In the dosing tank, add 1,2-propanediol to B12 under stirring, and continue stirring for 5 minutes to ensure uniform mixing. Ethyl lactate was then added to the mixture, followed by soybean oil. While continuing to stir, add ethoxyquinoline vitamins E, A, and D in turn. Finally, monoglyceride and Span 80 are added to the homogeneous liquid to make group A liquid vitamin ingredients;

[0034] Group B liquid vitamin batching, its composition ratio is as follows: biotin 0.2g / kg, pyridoxine hydrochloride (B 6 )3g / kg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com