Production method of shrimp meat wontons

A production method and technology of wontons, applied in the field of food processing, can solve the problems of poor foam resistance, unable to meet daily needs, easy to break skin, etc., and achieve the effect of poor foam resistance, enrich the market, and not easy to break skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

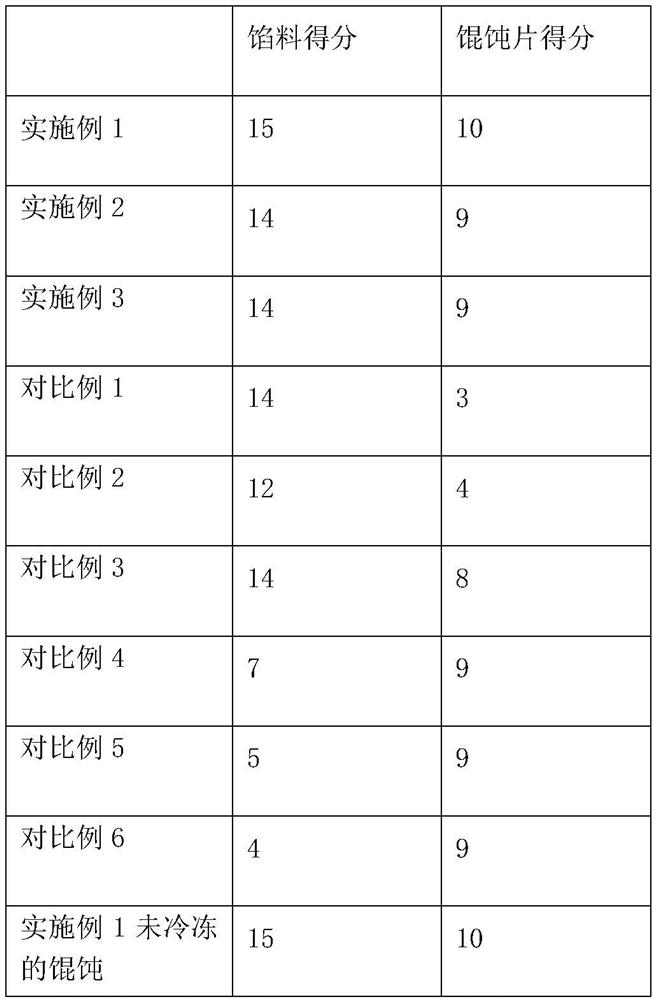

Examples

Embodiment 1

[0033] A production method of shrimp ravioli, comprising the following steps:

[0034] S1, the preparation of wonton skin:

[0035] The wonton skin is composed of the following raw materials in parts by weight: 68 parts of flour, 20 parts of rhubarb rice flour, 0.8 part of salt and 30 parts of water;

[0036] Stir the flour, rhubarb rice flour, salt and water evenly to make a dough, let the dough rest at 33°C for 35 minutes, then roll it into a dough with a thickness of 0.5mm, and cut the dough into wonton wrappers with a size of 8cmx9cm.

[0037] S2. Preparation of wonton stuffing:

[0038] The wonton stuffing consists of the following raw materials in parts by weight: 150 parts of shrimp, 38 parts of pork, 20 parts of diced vegetables, 5 parts of egg whites, 12 parts of pepper water, 2 parts of alkali, 0.4 parts of seasoning powder, 0.4 parts of liquid seasoning and 22 parts of water;

[0039] The preparation method of the Zanthoxylum bungeanum water is as follows: in par...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is:

[0046]The wonton wrapper described in step S1 consists of the following raw materials in parts by weight: 70 parts of flour, 30 parts of rhubarb rice flour, 1.2 parts of salt and 35 parts of water;

[0047] The wonton stuffing in step S2 is composed of the following raw materials in parts by weight: 200 parts of shrimp, 55 parts of pork, 25 parts of diced vegetables, 6 parts of egg white, 15 parts of pepper water, 3 parts of alkali, 0.5 parts of seasoning powder, liquid seasoning 0.5 parts and 25 parts of water;

[0048] The preparation method of the Zanthoxylum bungeanum water is as follows: in parts by weight, add 30 parts of water at a temperature of 70°C to 8 parts of green Zanthoxylum bungeanum, soak for 5 hours, filter, and the obtained filtrate is the Zanthoxylum bungeanum water; the alkali is edible Alkali powder; the liquid seasoning is a mixed solution of papain and extremely fresh taste with a mas...

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is:

[0051] The wonton wrapper described in step S1 consists of the following raw materials in parts by weight: 65 parts of flour, 15 parts of rhubarb rice flour, 0.6 part of salt and 25 parts of water;

[0052] The wonton stuffing in step S2 is composed of the following raw materials in parts by weight: 100 parts of shrimp, 25 parts of pork, 15 parts of diced vegetables, 3 parts of egg white, 10 parts of pepper water, 1 part of alkali, 0.3 parts of seasoning powder, liquid seasoning 0.3 parts and 20 parts of water;

[0053] The preparation method of the Zanthoxylum bungeanum water is as follows: in parts by weight, add 20 parts of water at a temperature of 60°C to 5 parts of green Zanthoxylum bungeanum, soak for 8 hours, filter, and the obtained filtrate is the Zanthoxylum bungeanum water; Alkali powder; the liquid seasoning is a mixture of papain and extremely fresh taste with a mass ratio of 1:4; the seasoning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com