Dust and mist remover with negative ion generating device

A negative ion generator and negative ion generation technology, applied in the field of flue gas purification, can solve the problems of low dust removal effect, high operating cost, large floor area, etc., achieve good dust removal and fog removal effect, convenient operation and maintenance, and low scaling risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiments. The description of the following embodiments is only used to help understand the present invention. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, several improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

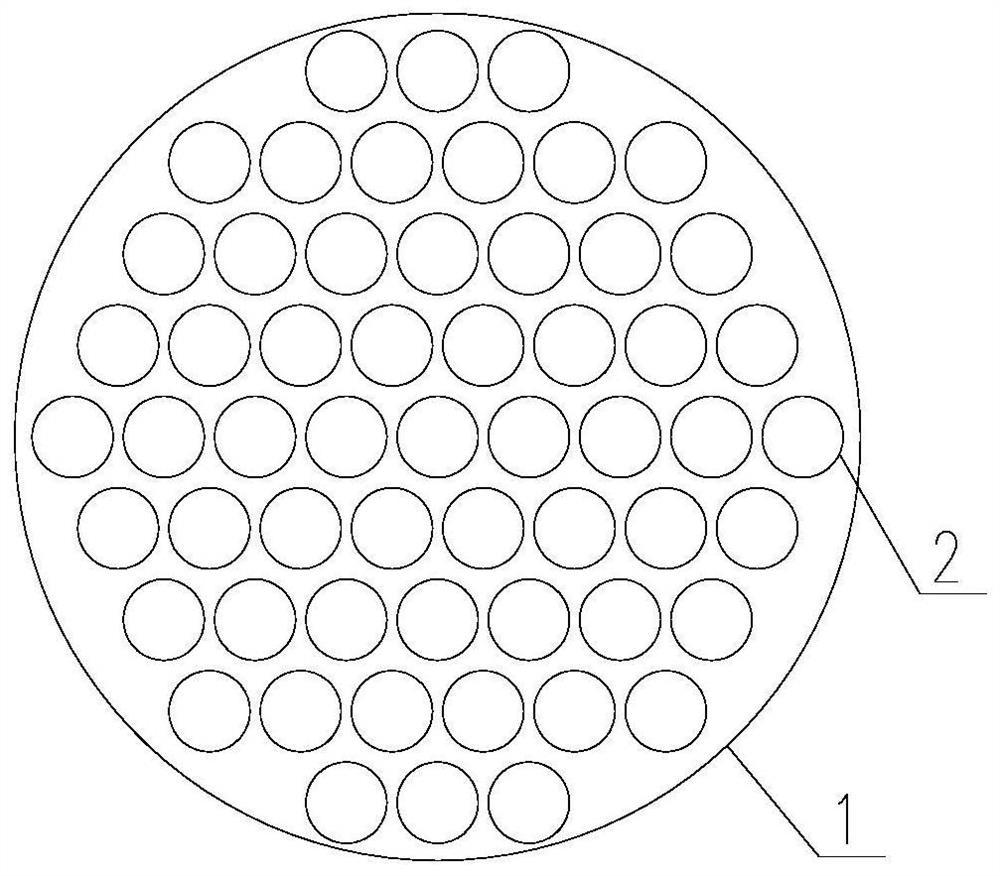

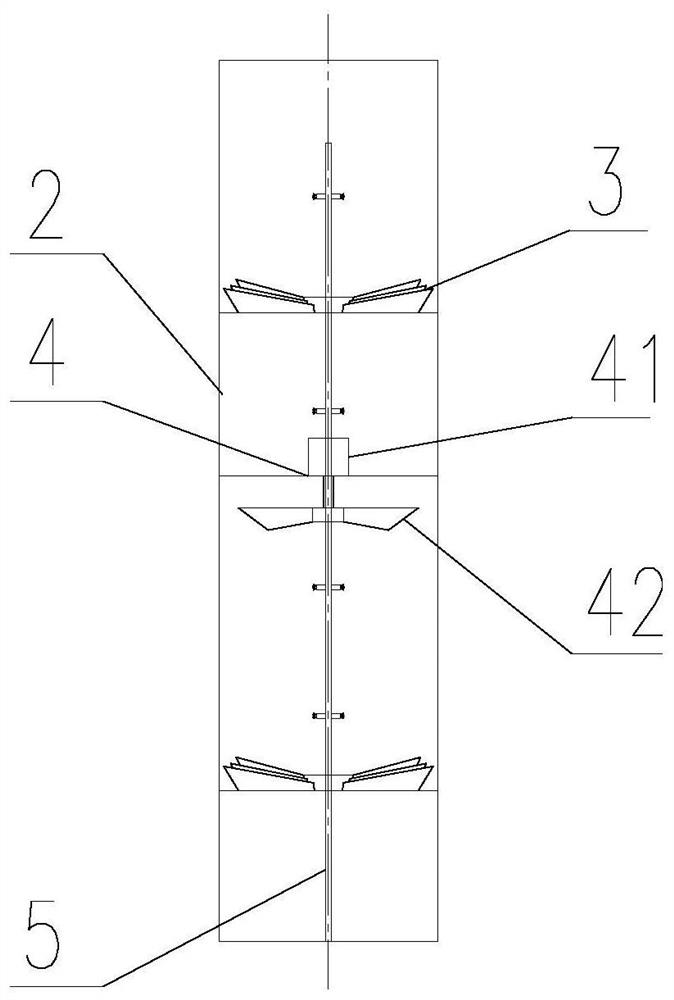

[0021] As an example, the dust and mist eliminator with a negative ion generating device is arranged in the desulfurization absorption tower and installed above the uppermost desulfurization slurry spray layer, and the saturated wet flue gas after desulfurization flows through the flue gas from bottom to top Dust removal and demister; the dust removal and demister is composed of a plurality of unit cylinders 2 for dust removal and demisting, the unit cylinders 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com