Color-changing coating and preparation system and method thereof

A preparation system and color-changing paint technology, which is applied in the field of color-changing paint and its preparation system and preparation, and can solve problems such as uneven stirring and affecting paint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

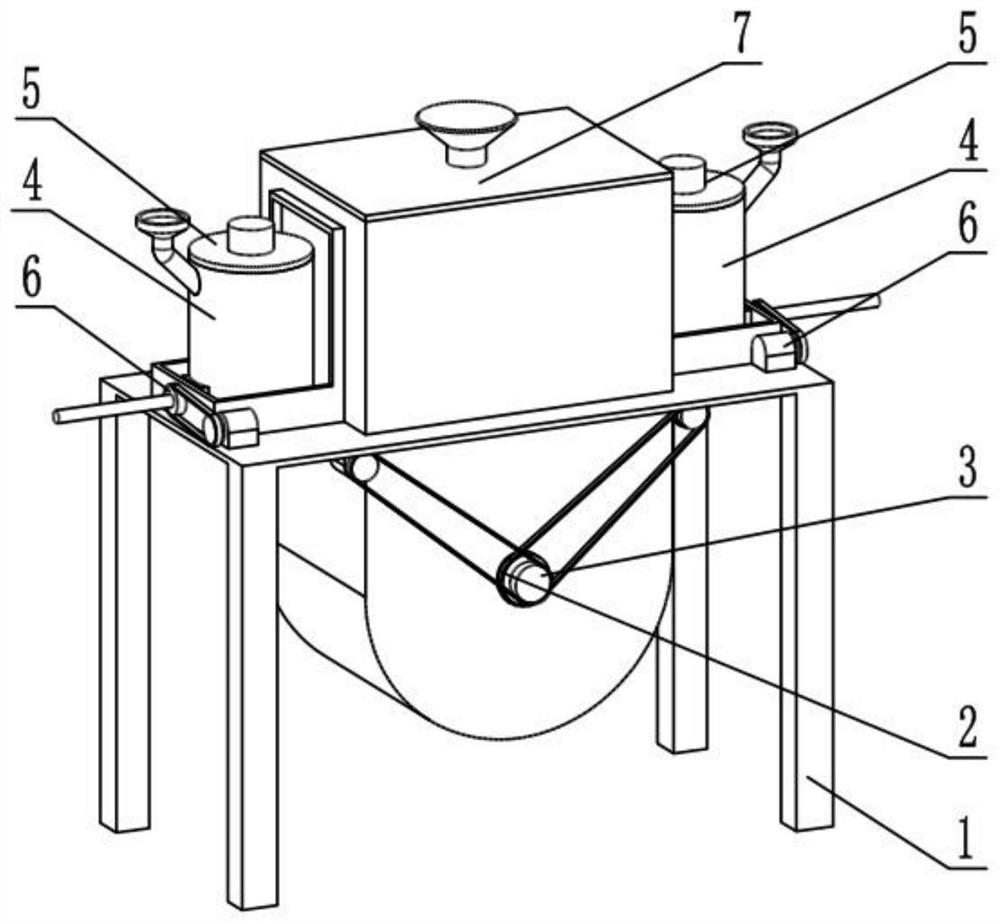

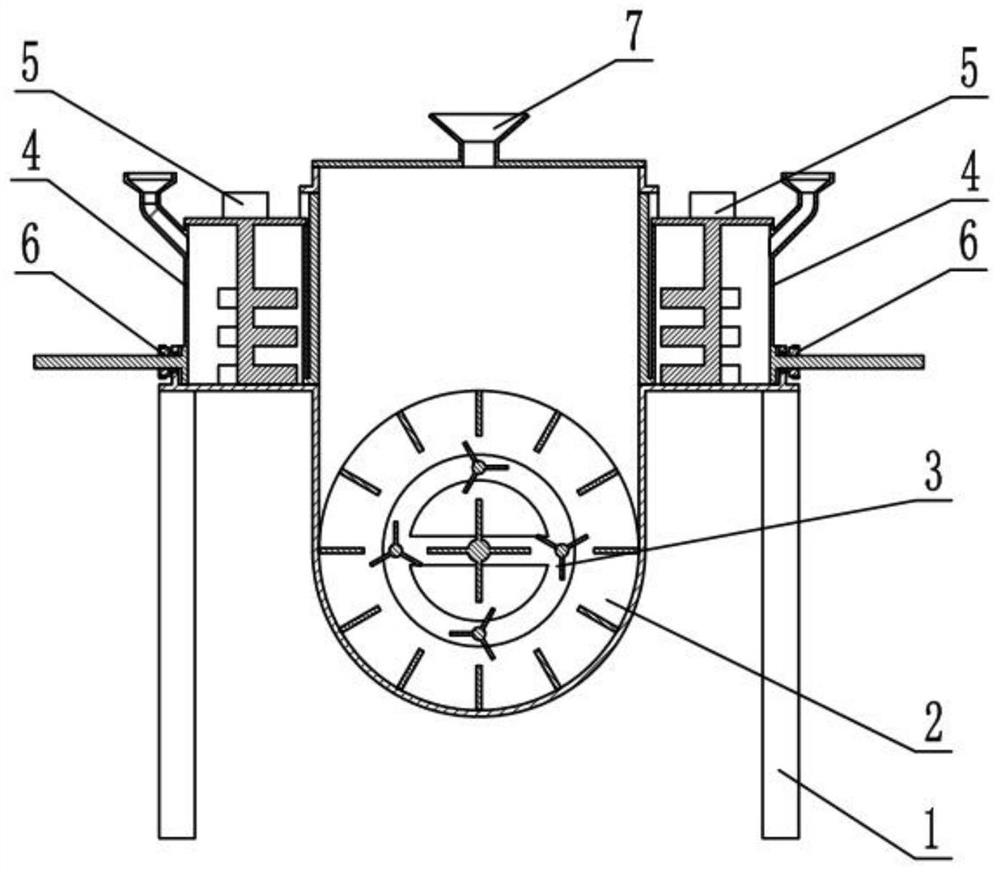

[0033] Such as Figure 1-10 As shown, a color-changing paint preparation system includes a stirring main frame 1, an external stirring mechanism 2, an internal stirring mechanism 3, a moving stirring frame 4, a batching stirring mechanism 5, a moving power mechanism 6 and an upper cover mechanism 7. The stirring mechanism 2 is rotatably connected in the stirring main frame 1, and the inner stirring mechanism 3 is rotatably connected in the outer stirring mechanism 2 and is fixedly connected with the stirring main frame 1, and the outer stirring mechanism 2 and the inner stirring mechanism 3 rotate in opposite directions. The mobile stirring frame 4 is provided with two, and the two mobile stirring frames 4 are symmetrically slidably connected to the left and right ends of the stirring main frame 1, and the described batching stirring mechanism 5 is provided with two, and the two batching stirring mechanisms 5 are respectively rotated and connected. In the two mobile stirring f...

specific Embodiment approach 2

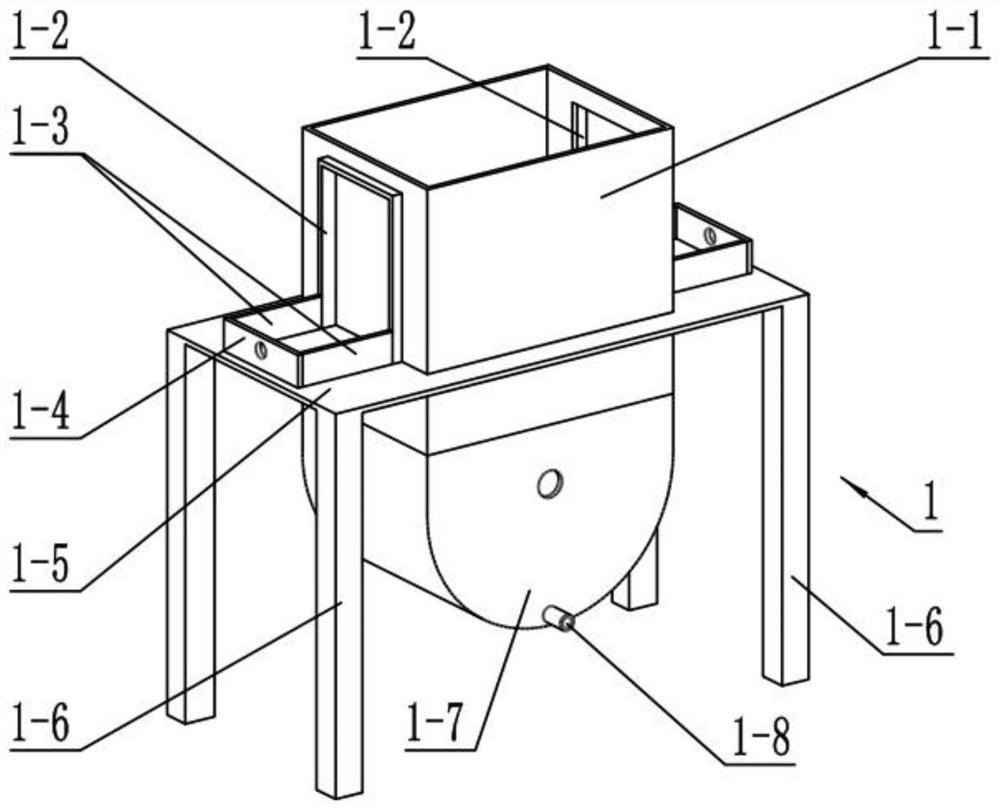

[0036] Such as Figure 1-10 As shown, the stirring main frame 1 includes a stirring rectangular tube 1-1, a channel tube 1-2, a limiting plate 1-3, a connecting plate 1-4, a supporting main board 1-5, a supporting leg 1-6, a stirring Semi-cylinder 1-7 and discharge pipe 1-8, the lower end of stirring rectangular pipe 1-1 is provided with stirring semi-cylinder 1-7, the lower end of stirring semi-cylinder 1-7 is provided with discharge pipe 1-8, discharge pipe 1-8 is provided with a valve, the stirring rectangular tube 1-1 is fixedly connected to the center of the supporting main board 1-5, and the four corners of the supporting main board 1-5 are fixedly connected with supporting legs 1-6, and the stirring rectangular tube 1-1 Channel tubes 1-2 are provided on the left and right sides, and the outer ends of the two channel tubes 1-2 are provided with two limiting plates 1-3, and the four limiting plates 1-3 are fixedly connected to the supporting main board 1- 5, the outer en...

specific Embodiment approach 3

[0039] Such as Figure 1-10 As shown, the external stirring mechanism 2 includes an external stirring motor 2-1, a front circular plate 2-2, a transmission wheel 2-3, a rotating circular tube 2-4, a stirring outer plate 2-5, and a rear circular plate 2- 6 and the gear ring 2-7, the front circular plate 2-2 and the rear circular plate 2-6 are coaxially arranged, and there are a plurality of stirring outer plates uniformly fixedly connected in the circumferential direction between the front circular plate 2-2 and the rear circular plate 2-6 The center of the plate 2-5, the front circular plate 2-2 and the rear circular plate 2-6 are all fixedly connected with a rotating circular tube 2-4, and the rotating circular tube 2-4 at the front end is fixedly connected with a drive wheel 2-3 , the inner surface of the front circular plate 2-2 is fixedly connected with a toothed ring 2-7, the toothed ring 2-7 is coaxial with the front circular plate 2-2, and the two rotating tubes 2-4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com