Supported alloy catalyst as well as preparation method and application thereof

An alloy catalyst and supported technology, which is applied in the field of supported alloy catalyst and its preparation, can solve the problems of by-product environmental pollution, low catalytic activity, and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

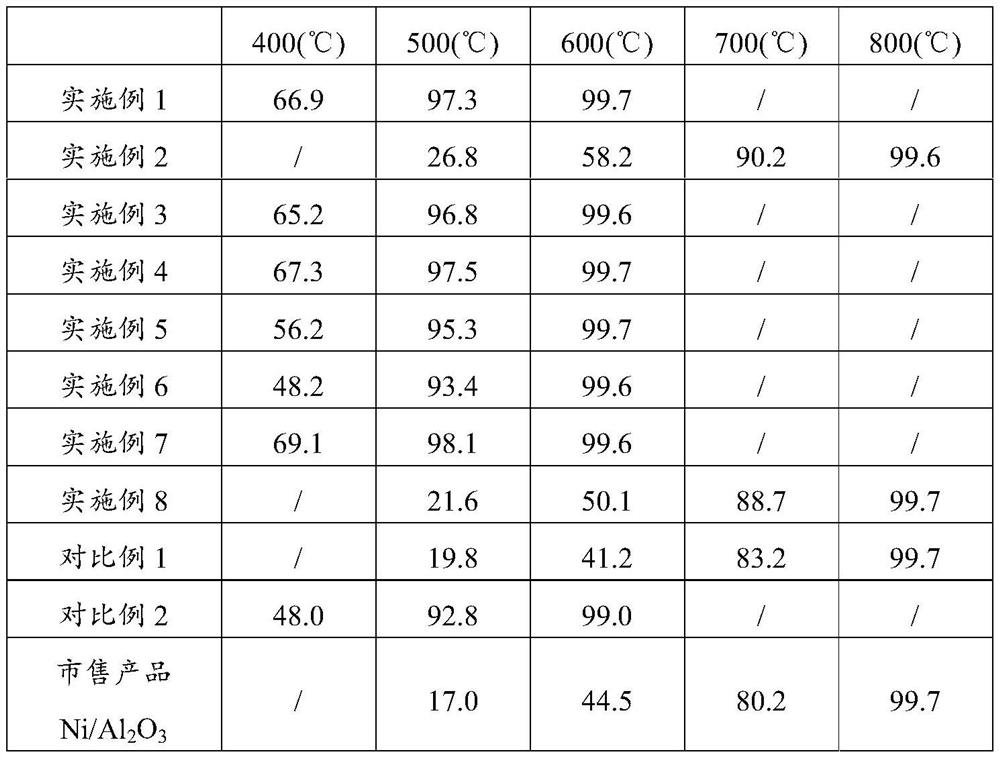

Examples

Embodiment 1

[0038] The present embodiment provides a supported alloy catalyst, and the preparation method of the catalyst is as follows:

[0039] 0.2463g of RuCl 3 and 10.1478 g of ZrOCl 2 ·8H 2 Add O to 100mL of water, mix evenly to obtain a mixed solution, add the above mixed solution and 100mL of potassium hydroxide solution with a substance concentration of 1.0mol / L dropwise into a water bath at 70°C, and control the pH of the solution to about 10.0 , and reacted for 2 hours to obtain a suspension; then 4.0 mL of 0.3 mol / L potassium borohydride solution was added dropwise to the above suspension, and the reaction was continued for 2 hours; the precipitate was washed by centrifugation, dried in vacuum at 60°C for 12 hours, and placed in an Ar atmosphere of 550°C Roasting for 2h, wherein, the heating rate of the calcination step is 1.0°C / min, that is, Ru-B / ZrO 2 Catalyst, wherein, Ru load 3.0wt%.

Embodiment 2

[0041] The present embodiment provides a supported alloy catalyst, and the preparation method of the catalyst is as follows:

[0042] 1.4946g of Ni(NO 3 ) 2 and 8.8896g of Ce(NO 3 ) 3 ·6H 2 O was added to 100mL of water, mixed evenly to obtain a mixed solution, and the above mixed solution and 100mL of sodium carbonate solution with a substance concentration of 2.0mol / L were added dropwise into a water bath at a temperature of 80°C, and the pH value of the control system was about 10.5 , reacted for 2h to obtain a suspension; then, 16.5mL of 0.5mol / L NaH 2 PO 2 The solution was added dropwise to the above suspension, and the reaction was continued for 2 hours; the precipitate was washed by centrifugation, dried in vacuum at 60°C for 12 hours, and calcined at 550°C in Ar atmosphere for 2 hours, wherein the heating rate of the calcining step was 1.0°C / min to obtain Ni-P / CeO 2 Catalyst, Ni loading 12.0wt%.

Embodiment 3

[0044] The present embodiment provides a supported alloy catalyst, and the preparation method of the catalyst is as follows:

[0045] 0.2466g of RuCl 3 and 10.1475 g of ZrOCl 2 ·8H2 Add O to 100mL of water, mix evenly to obtain a mixed solution, add the above mixed solution and 100mL of potassium hydroxide solution with a substance concentration of 1.0mol / L dropwise into a water bath at 60°C, and control the pH value of the solution to about 10.0 , and reacted for 4 hours to obtain a suspension; then 4.0 mL of 0.3 mol / L potassium borohydride solution was added dropwise to the above suspension, and the reaction was continued for 4 hours; the precipitate was washed by centrifugation, dried in vacuum at 60°C for 12 hours, and placed in an Ar atmosphere of 550°C Roasting for 2h, wherein, the heating rate of the calcination step is 1.0°C / min, that is, Ru-B / ZrO 2 Catalyst, wherein, Ru load 3.0wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com