Catalyst carrier, ammonia decomposition catalyst and preparation method

A catalyst carrier, catalyst technology, applied in catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of low interaction strength, affecting catalyst activity and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

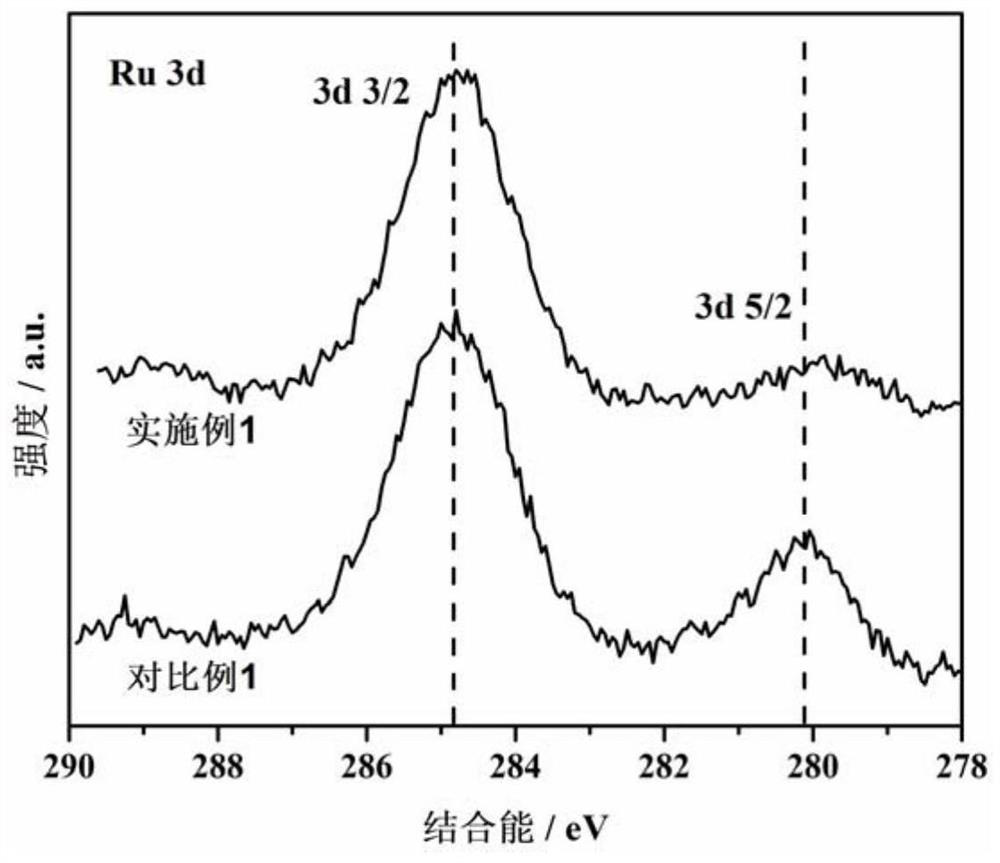

[0036] This embodiment provides an ammonia decomposition catalyst, including a carbon-modified boron nitride carrier and an active component Ru, wherein, in the carbon-modified boron nitride carrier, the doping amount of carbon is 5%, and in the active component, In terms of metal elements, the loading amount of Ru is 3%.

[0037] The preparation method of this catalyst is as follows:

[0038] Mix 11.8g of urea, 12.1g of boric acid, and 0.25g of activated carbon evenly, and perform calcination under a nitrogen atmosphere, wherein the calcination temperature is 900°C, and the calcination time is 4h, to obtain a carbon-modified boron nitride carrier;

[0039] Add 3.0 g of the above carbon-modified boron nitride carrier to 45.9 mL of RuCl with a molar concentration of 0.02 mol / L 3 The ammonia decomposition catalyst was obtained by step-by-step impregnation in the aqueous solution for five times, drying, and then roasting in a nitrogen atmosphere at a roasting temperature of 550°...

Embodiment 2

[0041] This embodiment provides an ammonia decomposition catalyst, including a carbon-modified boron nitride carrier and an active component Ni, wherein, in the carbon-modified boron nitride carrier, the doping amount of carbon is 5%, and in the active component, In terms of metal elements, the loading amount of Ni is 12%.

[0042] The preparation method of this catalyst is as follows:

[0043] Mix 11.8g of urea, 12.1g of boric acid, and 0.25g of activated carbon evenly, and perform calcination under a nitrogen atmosphere, wherein the calcination temperature is 900°C, and the calcination time is 4h, to obtain a carbon-modified boron nitride carrier;

[0044] Add 3.0 g of the above carbon-modified boron nitride carrier to 70 mL of Ni(NO 3 ) 2 The ammonia decomposition catalyst was obtained by step-by-step impregnation in the aqueous solution for seven times, drying, and then roasting in a nitrogen atmosphere at a roasting temperature of 900° C. for 2 hours.

Embodiment 3

[0046] This embodiment provides an ammonia decomposition catalyst, including a carbon-modified boron nitride carrier and an active component Ru, wherein, in the carbon-modified boron nitride carrier, the doping amount of carbon is 1%, and in the active component, In terms of metal elements, the loading amount of Ru is 1%.

[0047] The preparation method of this catalyst is as follows:

[0048] Mix 25.8g of melamine, 24.0g of boron chloride and 0.02g of polyvinyl alcohol uniformly, and perform calcination under a nitrogen atmosphere, wherein the calcination temperature is 800°C, and the calcination time is 12h, to obtain a carbon-modified boron nitride carrier;

[0049] Add 3.0 g of the above carbon-modified boron nitride carrier to 30 mL of Ru(NO 3 ) 3 In the aqueous solution, step-by-step impregnation was performed three times, dried, and then roasted in a nitrogen atmosphere at a roasting temperature of 550° C. for 6 hours to obtain the ammonia decomposition catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com