Preparation method of ethanol-SCR catalyst

A catalyst and ethanol technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as personal health and safety injuries, catalyst failure, and increase catalyst pressure drop, and achieve improved anti-fly ash and Carbon deposition ability, high NOx conversion rate, improved anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

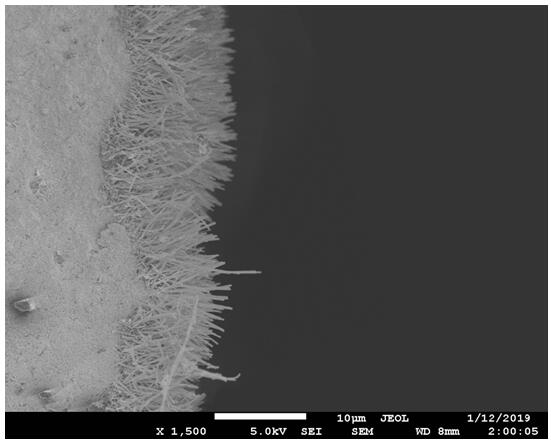

Image

Examples

Embodiment 1

[0026] The present embodiment prepares catalyst A, and concrete process is as follows:

[0027] (1) Put the honeycomb ceramic matrix into aluminum sol (solid content: 30wt%) for dip coating, then blow off the residual sol on the surface of the matrix and in the channels with compressed air, dry at 110°C for 3 hours, and bake at 600°C for 3 hours; Repeat the above process 2 times; the alumina coating coated on the honeycomb ceramic substrate accounts for 14% of the mass of the honeycomb ceramic substrate in terms of alumina;

[0028] (2) Put the material obtained in step (1) into a pressure-resistant container filled with ammonium bicarbonate aqueous solution (mass concentration: 17%), and carry out hydrothermal treatment at 130°C for 8 hours under airtight conditions to remove the residual liquid. Dry at 110°C for 6 hours, and bake at 500°C for 4 hours to obtain a coated honeycomb ceramic substrate; the mass ratio of the material obtained in step (1) to the ammonium bicarbonat...

Embodiment 2

[0032] The present embodiment prepares catalyst B, and concrete process is as follows:

[0033] (1) The process is the same as in Example 1; the alumina coating coated on the honeycomb ceramic substrate accounts for 18% of the mass of the honeycomb ceramic substrate in terms of alumina;

[0034] (2) Put the material obtained in step (1) into a pressure-resistant container filled with ammonium bicarbonate aqueous solution (mass concentration: 14%), and carry out hydrothermal treatment at 145°C for 6 hours under airtight conditions to remove the residual liquid. Dry at 110°C for 4 hours, and bake at 500°C for 4 hours to obtain a coated honeycomb ceramic substrate; the mass ratio of the material obtained in step (1) to the ammonium bicarbonate aqueous solution is 5:21;

[0035] (3) The process was the same as in Example 1 to obtain catalyst B, wherein the silver content in catalyst B was 1.0 wt%.

Embodiment 3

[0037] The present embodiment prepares catalyst C, and specific process is as follows:

[0038] (1) The process is the same as in Example 1; the difference is that the aluminum sol dip coating process is repeated once; the alumina coating coated on the honeycomb ceramic substrate accounts for 10% of the mass of the honeycomb ceramic substrate in terms of alumina. %;

[0039] (2) Put the material obtained in step (1) into a pressure-resistant container filled with ammonium bicarbonate aqueous solution (mass concentration: 14%), and conduct hydrothermal treatment at 140°C for 7 hours under airtight conditions to remove the residual liquid. Dry at 110°C for 3 hours, and bake at 500°C for 4 hours to obtain a coated honeycomb ceramic substrate; the mass ratio of the material obtained in step (1) to the ammonium bicarbonate aqueous solution is 1:6;

[0040] (3) The process was the same as in Example 1 to obtain catalyst C, wherein the silver content in catalyst C was 0.8wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com