A wood furniture processing waste recycling device

A waste recycling and processing device technology, applied in wood processing appliances, wood compression, manufacturing tools, etc., can solve the problems of waste materials, troublesome processing, inability to process high-quality particleboard, etc., and achieve easy transportation and storage, and reduce volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

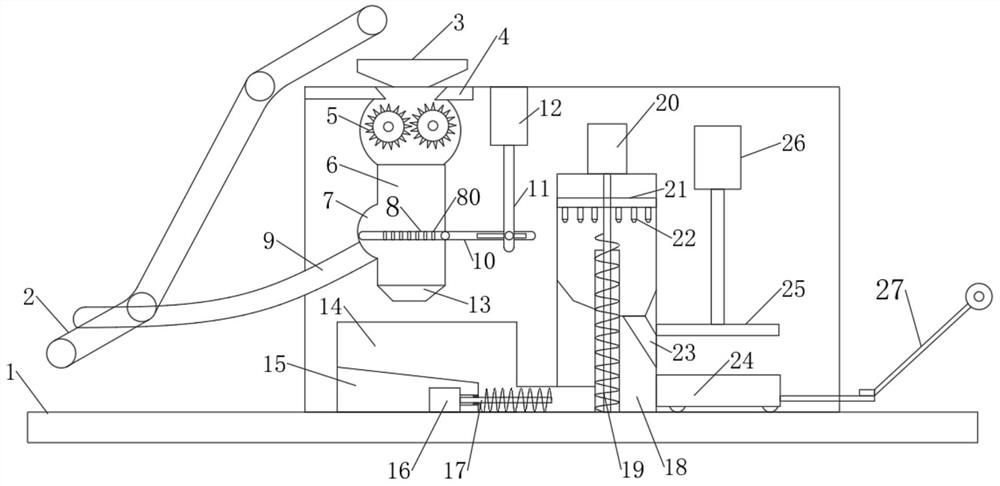

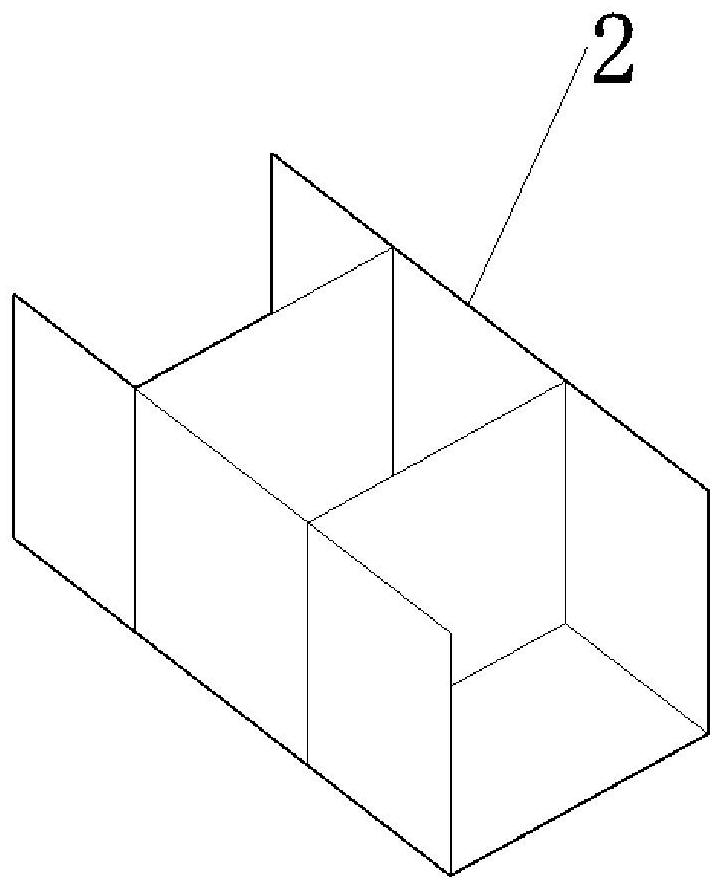

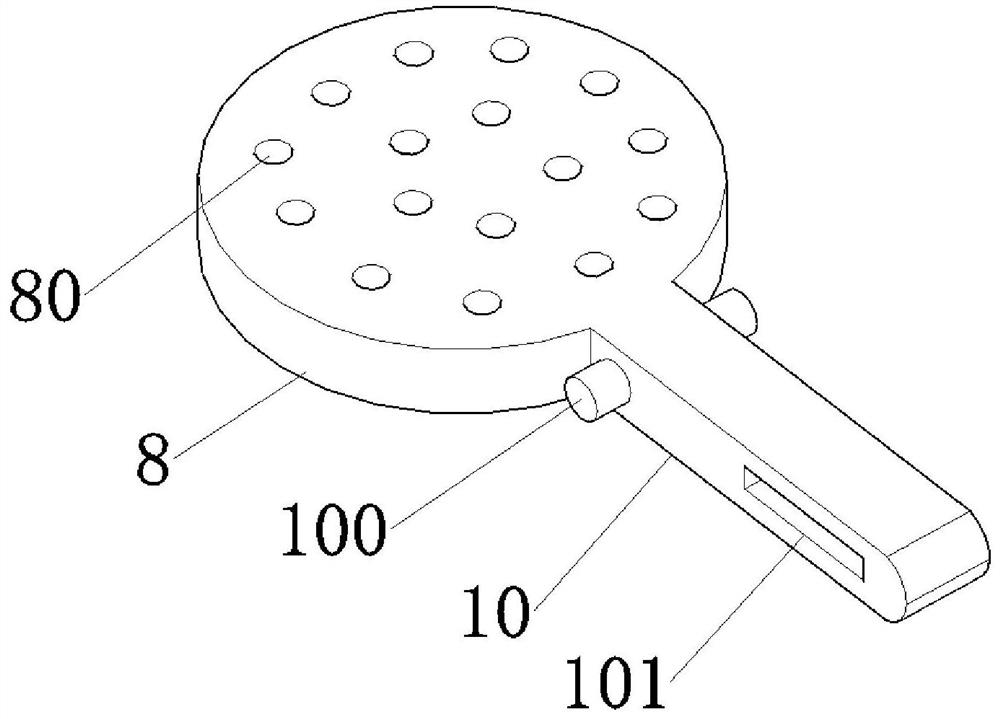

[0027] Such as Figure 1-3 As shown, a wood furniture processing waste recovery treatment device includes a base 1, a conveyor belt 2 is arranged above the base 1, and the end of the conveyor belt 2 is arranged on the upper side of a feed hopper 3, and the feed hopper 3 is connected to the The shells are connected, and the lower side of the feed hopper 3 is provided with a crushing cylinder 5, and the crushing cylinder 5 is connected with the lower material cylinder 6, and an arc-shaped groove 7 is arranged in the lower material cylinder 6, and the lower material cylinder The middle part of 6 is rotatably connected with a sieve plate 8, and sieve holes 80 are evenly arranged on the sieve plate 8, and the outer side of the sieve plate 8 is connected with a connecting rod 10, and a chute is arranged on the connecting rod 10 101, a telescopic rod 11 is slidably connected in the chute 101, the telescopic rod 11 is connected with the first cylinder 12, and a return pipe 9 is arrang...

Embodiment 2

[0041] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0042] A wood furniture processing waste recycling device, including all the parts in embodiment 1, also includes:

[0043] Further, a mounting plate 21 is disposed on the upper side of the second conveying roller 19 , and spray heads 22 are evenly disposed on the lower side of the mounting plate 21 .

[0044] Specifically, in order to further process the crushed debris, the debris is lifted by setting the first conveying roller 17 and the second conveying roller 19, and the debris is sprayed with an auxiliary agent in combination with the spray head 22 on the mounting plate 21, It is convenient for the subsequent extrusion operation of the debris.

[0045] The working principle of the embodiment of the present invention is:

[0046] Such as Figure 1-3 As shown, by crushing wood waste in the crushing cylinder 5, by setting an arc-shaped groove 7 in the lower mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com