Automatic sorting and sample loading assembly for soil samples

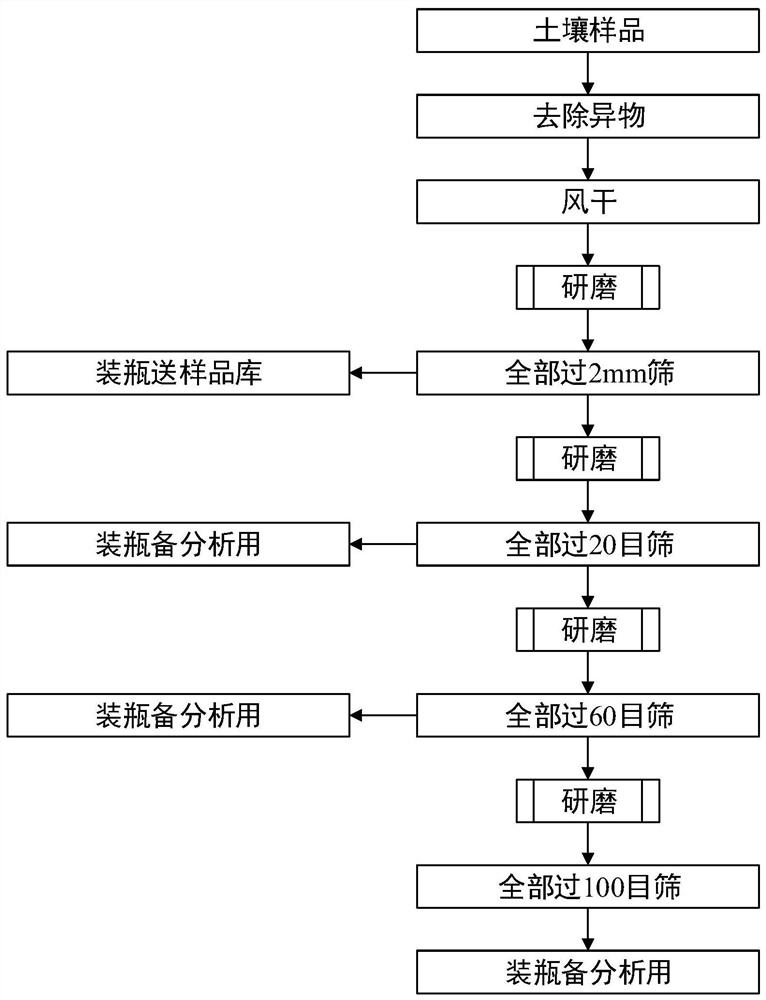

An automatic sorting and soil sample technology, applied in the preparation of test samples, special packaging objects, packaging, etc., can solve the problems of heavy workload, low sample preparation efficiency, long cycle, etc., to achieve automation and improve sample preparation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

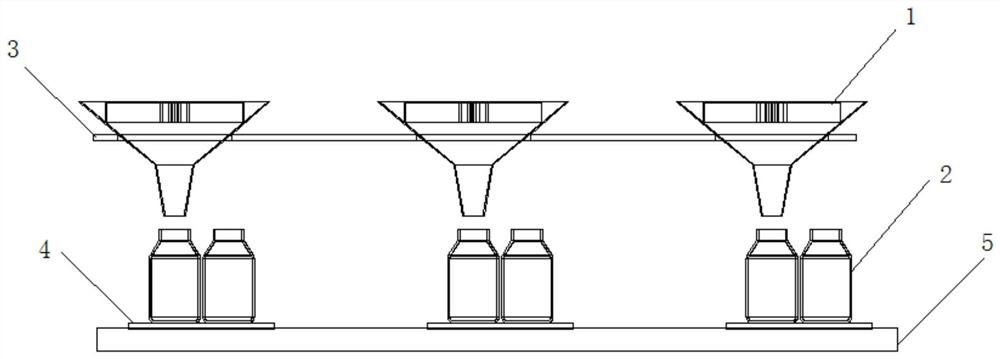

[0018] Embodiment 1: see attached figure 2 , an automatic sorting sample loading assembly for soil samples, the sample loading assembly is divided into upper and lower layers, including: a quarter funnel 1 on the upper layer and a sample loading container 2 on the lower layer;

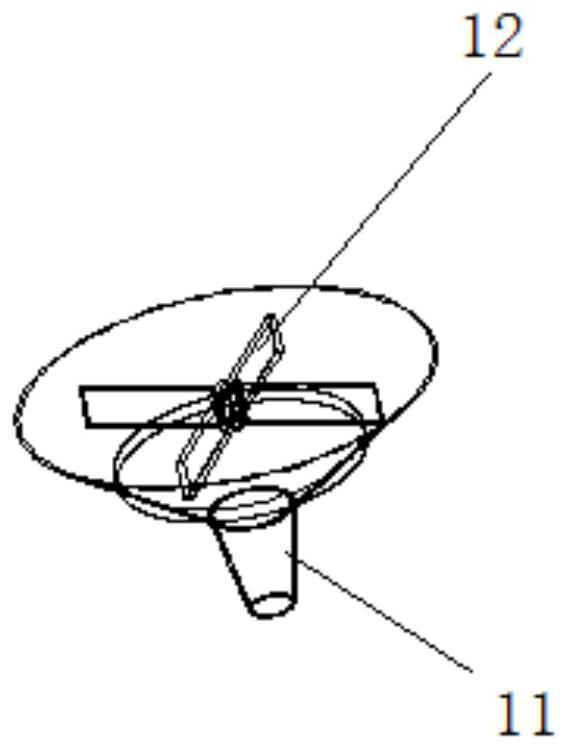

[0019] See attached image 3 , the four-point funnel 1 includes: funnel 11 and cross-shaped partition 12; cross-shaped partition 12 divides the inside of funnel 11 into four fan-shaped areas of equal parts, wherein a group of diagonal fan-shaped areas are open at the bottom, and the other group is paired The bottom of the fan-shaped area of the corner is closed; further, in order to facilitate the gripping of the four-point funnel 1 by the manipulator, the outer wall of the four-point funnel 1 can also be provided with a positioning and clamping boss;

[0020] During sample loading, the outlet of the quarter funnel 1 is opposite to the opening of the sample loading container 2 .

[0021] Further, ...

Embodiment 2

[0024] Example 2: On the basis of Example 1, according to the soil sample preparation process, it is necessary to load the soil samples that have passed through a 20-mesh sieve, a 60-mesh sieve, and a 100-mesh sieve. Therefore, in this example, the quarter funnel 1 There are 3 samples, which are respectively used to receive soil samples of 20 mesh, 60 mesh, and 100 mesh; correspondingly, there are 3 assembled sample containers 2, and each assembled sample container 2 is equipped with 5 sub-package bottles.

[0025] Taking the 20-mesh soil sample as an example, by scanning the barrel containing the soil sample, it is confirmed that the 20-mesh soil sample is bottled this time, and then by adjusting the position of the rotating frame 4, the bottle mouth of the 20-mesh bottle is Aim at a quarter funnel 1; the manipulator transports the material frame containing the 20-mesh soil sample to the top of the quarter funnel 1, and pours the soil sample to the center of the cross-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com