Winding assembly for continuous foaming material

A technology of winding components and foaming materials, applied in the direction of thin material processing, coiling strips, applications, etc., can solve problems affecting the quality and performance of plates, increasing the size deviation of finished products, and affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

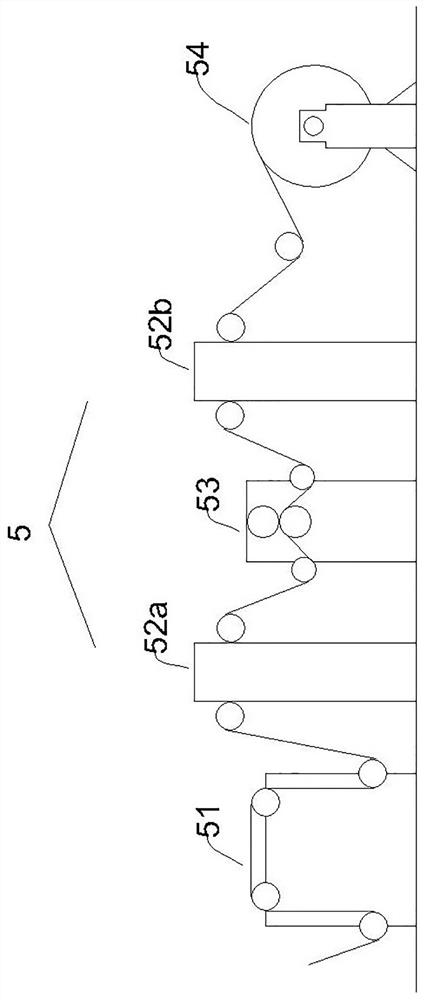

[0021] A winding assembly of continuous foam material such as figure 1 As shown, it includes a deviation correcting machine 51, a first tension machine 52a, a traction machine 53, a second tension machine 52b and a winding frame 54 arranged in sequence.

[0022] The deviation correcting machine 51 includes a frame and four rollers fixed on the frame. The deviation correcting machine 51 checks the correctness of the position through an infrared detector, and adjusts the direction of the frame through an automatic controller to correct the direction of foam material delivery. In order to avoid the influence of the deflection of the foam material on the thickness setting.

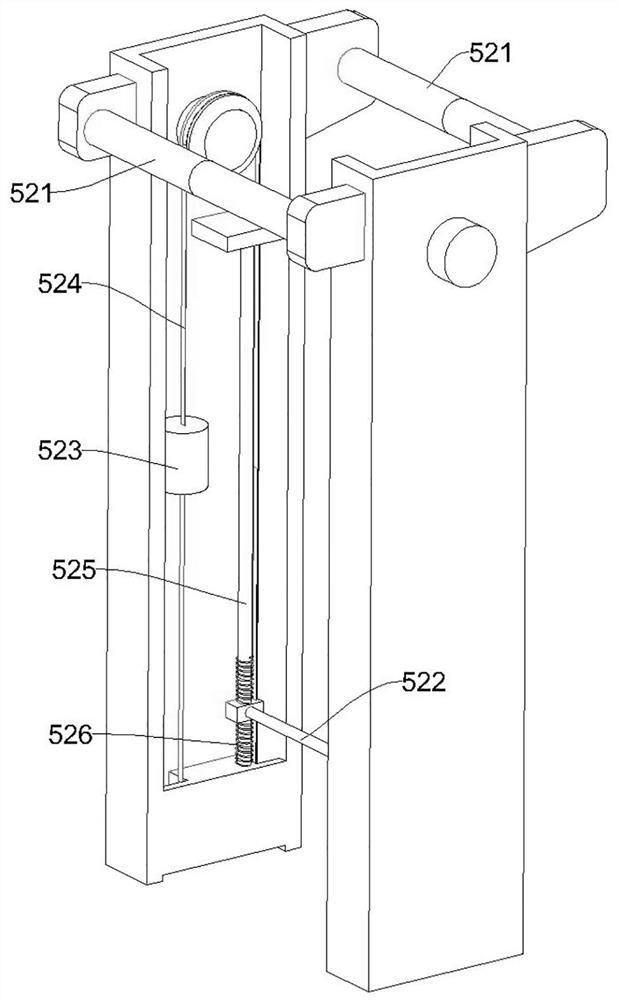

[0023] The structure of the first tension machine 52a is the same as that of the second tension machine 52b, as figure 2 As shown, it includes a floating roller 522 in the middle and two guide rollers 521 located on both sides of the floating roller 522 and above the floating roller 522. The guiding roller 5...

Embodiment 2

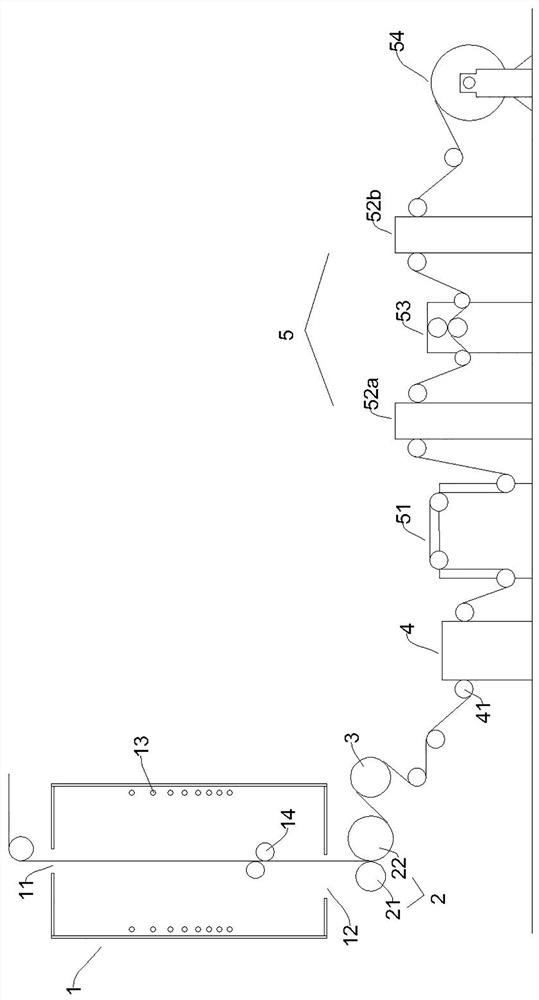

[0025] This embodiment is a preferred production system for the continuous foaming material comprising the winding assembly described in Embodiment 1, such as image 3 As shown, it includes a calibrating device, a cooling roll 3 , a corona machine 4 and a winding assembly 5 arranged in sequence.

[0026] The thickness fixing device includes a foaming chamber 1 and a thickness locking part 2; in the present embodiment, the foaming chamber 1 is a vertical foaming chamber, and the upper and lower ends are respectively provided with a feed port 11 and a discharge port 12. The inner wall of the bubble chamber 1 is provided with several heating elements 13 along the foaming material delivery direction, and the heating elements 13 are arranged in the middle part of the inner wall of the foaming furnace 1, and an unfolding roller 14 is arranged below the setting area of the heating element 13, and the unfolding roller 14 is hollow inside, and is provided with cooling water inlet. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com