A modified recycled composite plastic and its preparation method

A composite plastic and recycled plastic technology, applied in the field of polymer materials, can solve the problems affecting the use range and service life, poor mechanical properties of recycled plastic parts, different processing properties, etc., to achieve low interfacial energy, improve mechanical properties, good The effect of the cross-linked structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

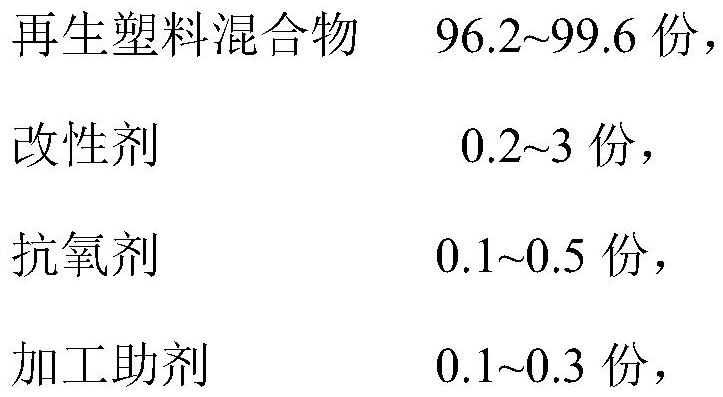

Method used

Image

Examples

Embodiment 1

[0024] 98.1 parts of the recycled plastic mixture (which contains PP 23.40%, PE 1.27%, ABS73.43%), modifier 4-epoxymethyl-3-phenylpiperazine-1-carboxylate tert-butyl 1.5 parts, 0.2 parts of antioxidant 1010, and 0.2 parts of processing aid calcium stearate were mixed uniformly in a high-mixer to obtain a mixed material;

[0025] Put the mixed material in a twin-screw extruder, and the processing temperature of each section: 250°C for the first zone, 255°C for the second zone, 270°C for the third zone, 270°C for the fourth zone, 270°C for the fifth zone, 270°C for the sixth zone, and 270°C for the seventh zone ℃, 260 ℃ in the eighth zone, 260 ℃ in the ninth zone, melt extrusion under the conditions of screw speed 250r / min, granulation and drying, to prepare modified recycled composite plastics.

Embodiment 2

[0027] 97.45 parts of the recycled plastic mixture (which contains PP 52.52%, ABS 16.43%, PC28.50), modifier 4-epoxymethyl-3-phenylpiperazine-1-carboxylate tert-butyl 2 0.3 part, 1076 parts of antioxidant, 0.25 part of processing aid silicone E5250.25 parts are mixed homogeneously in high mixer, obtain mixed material;

[0028] Put the mixed material in a twin-screw extruder, and the processing temperature of each section: 260°C for the first zone, 270°C for the second zone, 280°C for the third zone, 280°C for the fourth zone, 290°C for the fifth zone, 290°C for the sixth zone, and 280°C for the seventh zone ℃, 270°C in the eighth zone, 270°C in the ninth zone, melt extrusion under the condition of the screw speed of 220r / min, granulate and dry, and prepare the modified recycled composite plastic.

Embodiment 3

[0030] 96.95 parts of the recycled plastic mixture (which contains PP 40.31%, PE 23.78%, PC32.86%), modifier 4-epoxymethyl-3-phenylpiperazine-1-carboxylate tert-butyl 2.5 parts, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.1 part of processing aid zinc stearate were uniformly mixed in a high mixer to obtain a mixed material;

[0031] Put the mixed material in a twin-screw extruder, and the processing temperature of each section: 250°C for the first zone, 255°C for the second zone, 270°C for the third zone, 270°C for the fourth zone, 270°C for the fifth zone, 270°C for the sixth zone, and 270°C for the seventh zone ℃, 260°C in the eighth zone, 260°C in the ninth zone, melt extrusion under the condition of the screw speed of 280r / min, granulate and dry, and prepare the modified recycled composite plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com